Preparation method of nitrogen and sulfur co-doped graphene oxide grafted polyaniline/MoS2 electrode

A technology of nitrogen-sulfur co-doping and graphene, which is applied in the field of composite materials and electrochemical materials, can solve the problems of performance degradation and agglomeration, and achieve the effects of enhanced electronegativity, light weight and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

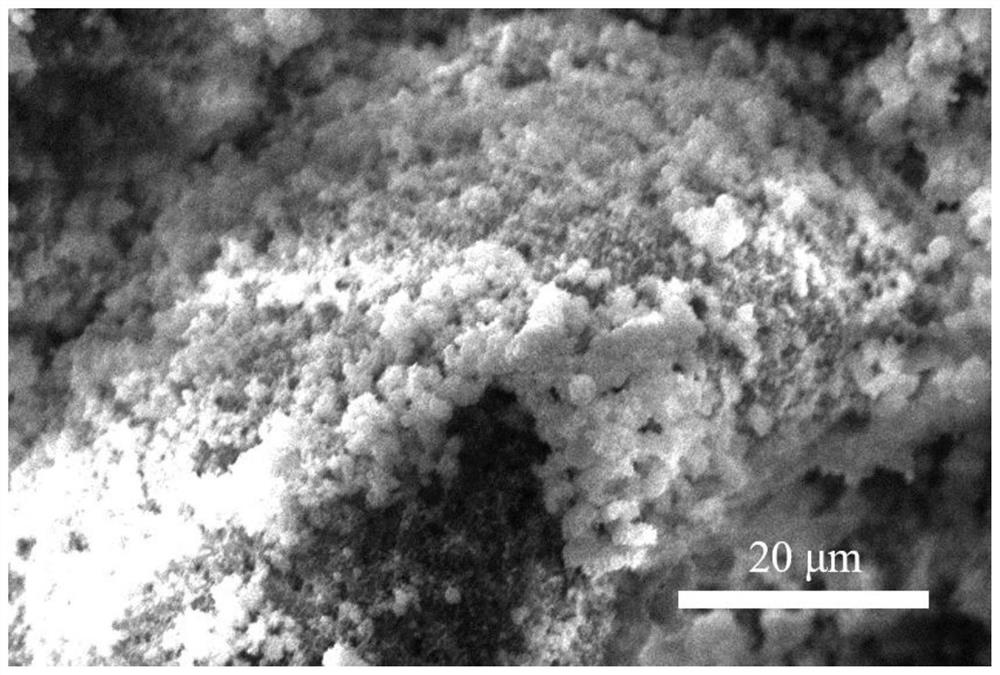

Image

Examples

Embodiment 1

[0039] This example provides a nitrogen-sulfur co-doped graphene oxide grafted polyaniline / MoS 2 The preparation method of electrode specifically comprises the following steps:

[0040] 1) Preparation of nitrogen and sulfur co-doped graphene oxide

[0041] Add 1.3 g of graphene oxide, 5 g of sodium dodecylbenzenesulfonate and 300 mL of deionized water into a three-necked flask, and stir magnetically at room temperature to form a dispersion. Add 0.2g pyrrole, 0.1g thiophene and 1.8g FeCl to the dispersion 3 , continue to stir and react for 12 hours, and the product is filtered, washed and dried to obtain a graphene oxide / polypyrrole / polythiophene composite. Soak the complex in 100 mL of ammonium chloride solution with a mass concentration of 1.2% for 12 hours, wash and dry. The compound was put into a tube furnace, and under the protection of argon, the temperature was raised from 25°C to 270°C and kept for 2h, then the temperature was raised from 270°C to 780°C and kept for...

Embodiment 2

[0051] This example provides a nitrogen-sulfur co-doped graphene oxide grafted polyaniline / MoS 2 The preparation method of electrode specifically comprises the following steps:

[0052] 1) Preparation of nitrogen and sulfur co-doped graphene oxide

[0053] Add 1.4 g of graphene oxide, 5 g of sodium dodecylbenzenesulfonate and 300 mL of deionized water into a three-necked flask, and stir magnetically at room temperature to form a dispersion. Add 0.3g pyrrole, 0.1g thiophene and 1.8g FeCl to the dispersion 3 , continue to stir and react for 12 hours, and the product is filtered, washed and dried to obtain a graphene oxide / polypyrrole / polythiophene composite. Soak the complex in 100 mL of 1% ammonium chloride solution for 12 hours, wash and dry. The compound was put into a tube furnace, and under the protection of argon, the temperature was raised from 25°C to 290°C and kept for 2h, then the temperature was raised from 290°C to 780°C and kept for 2h to obtain nitrogen-sulfur c...

Embodiment 3

[0063] This example provides a nitrogen-sulfur co-doped graphene oxide grafted polyaniline / MoS 2 The preparation method of electrode specifically comprises the following steps:

[0064] 1) Preparation of nitrogen and sulfur co-doped graphene oxide

[0065] Add 1.2 g of graphene oxide, 5 g of sodium dodecylbenzenesulfonate and 300 mL of deionized water into a three-necked flask, and stir magnetically at room temperature to form a dispersion. Add 0.4g pyrrole, 0.1g thiophene and 1.8g FeCl to the dispersion 3 , continue to stir and react for 12 hours, and the product is filtered, washed and dried to obtain a graphene oxide / polypyrrole / polythiophene composite. Soak the complex in 100 mL of ammonium chloride solution with a mass concentration of 1.1% for 12 hours, wash and dry. The compound was put into a tube furnace, and under the protection of argon, the temperature was raised from 25°C to 300°C and kept for 2h, and then the temperature was raised from 300°C to 780°C and kept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com