Silver nanowire and preparation method thereof

A technology of nano-silver wire and silver nitrate, which is applied in the field of preparation of new precious metal powder materials, can solve the problems of uneven conductive film surface, long preparation time, and decreased conductive function of the film layer, and achieves good uniformity in length and diameter, and synthesis The process is easy to operate and the effect of improving the conductivity efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

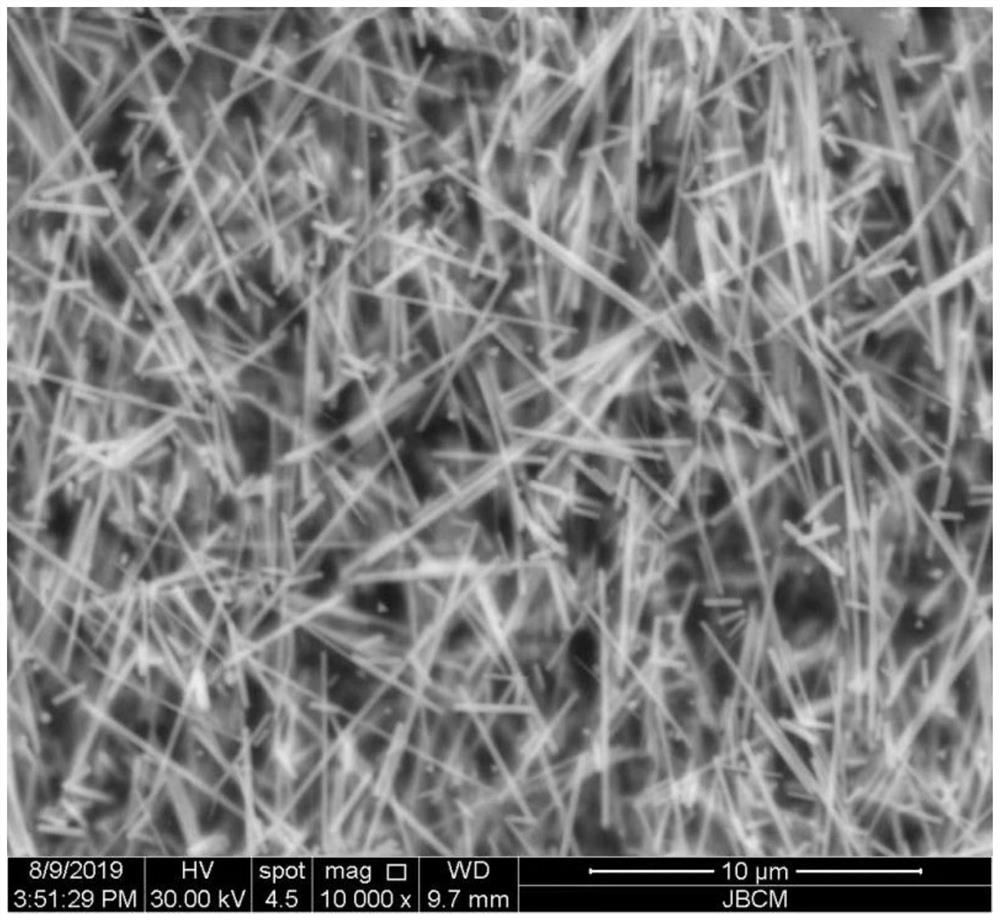

Embodiment 1

[0048] (1) Take 8g of silver nitrate and dissolve it in 40mL of ethylene glycol, stir to form solution B;

[0049] (2) Dissolve 26g of polyvinylpyrrolidone K30 in 100mL of ethylene glycol, stir to form solution A, heat solution A to 180°C in a magnetic stirrer, add 1mL of the above dissolved solution B and 200uL of hydrazine hydrate, and stir After 1 minute, add the remaining solution B above to solution A at a rate of 10mL / min, and keep warm at 180°C for 1 hour after the addition is completed;

[0050] (3) After cooling down, wash with water, wash with ethanol, and centrifuge to obtain silver nanowire 1#.

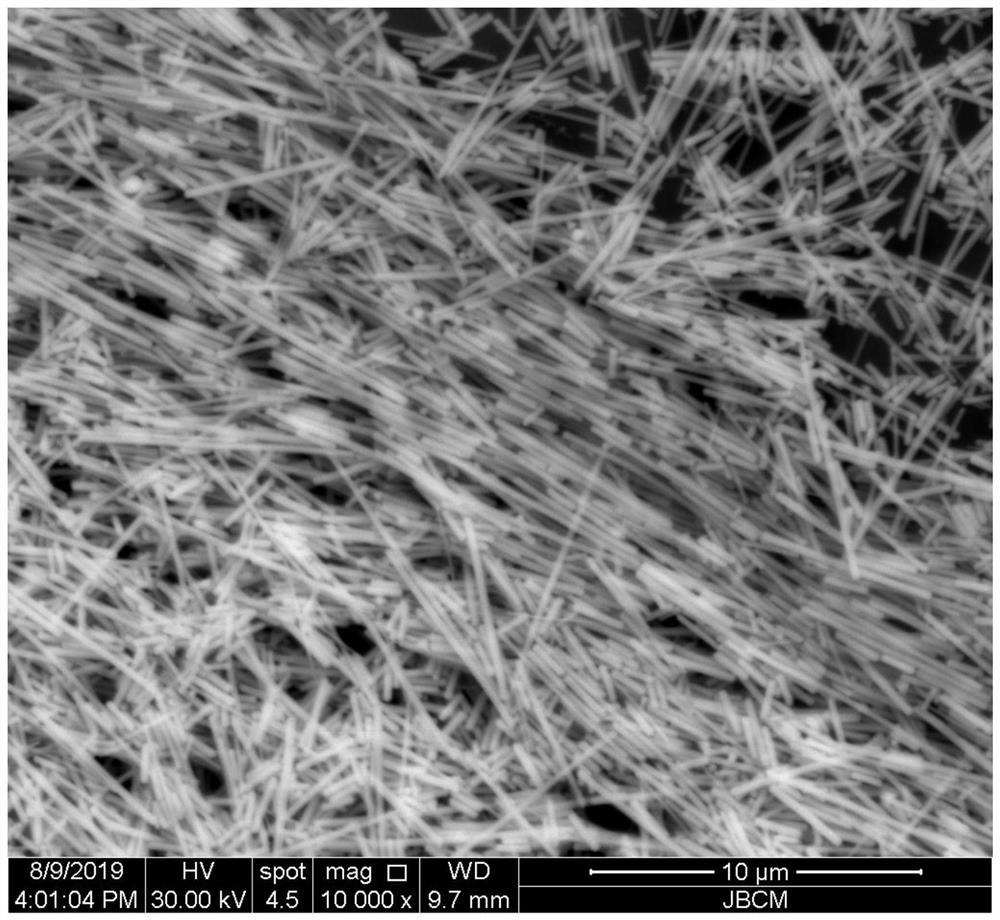

Embodiment 2

[0052] (1) Take 8g of silver nitrate and dissolve it in 40mL of ethylene glycol, stir to form solution B;

[0053] (2) Dissolve 16g of polyvinylpyrrolidone K30 in 100mL of ethylene glycol, stir to form solution A, heat solution A to 180°C in a magnetic stirrer, add 1mL of the above dissolved solution B and 200uL of hydrazine hydrate, and stir After 1 minute, add the remaining solution B above to solution A at a rate of 10mL / min, and keep warm at 180°C for 1 hour after the addition is completed;

[0054] (3) After cooling down, wash with water, wash with ethanol, and centrifuge to obtain silver nanowire 2#.

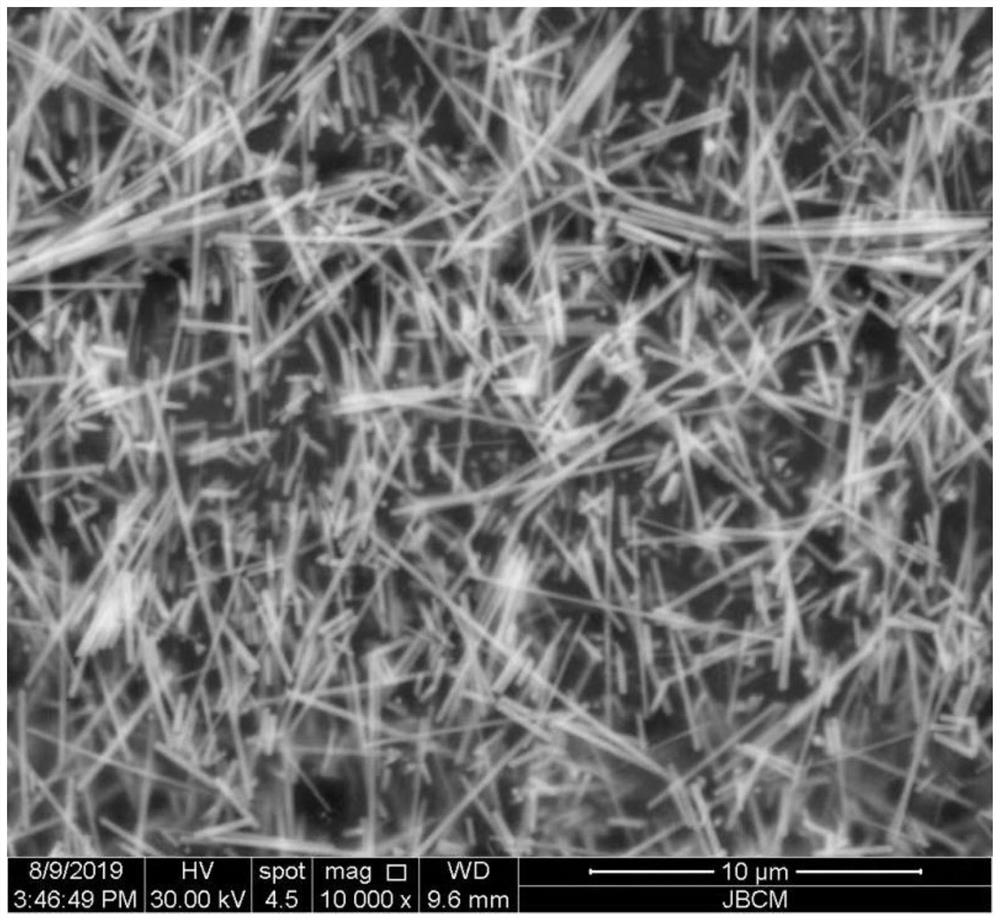

Embodiment 3

[0056] (1) Take 8g of silver nitrate and dissolve it in 40mL of ethylene glycol, stir to form solution B;

[0057] (2) Dissolve 16g of polyvinylpyrrolidone K30 in 100mL of ethylene glycol, stir to form solution A, heat solution A to 160°C in a magnetic stirrer, add 1mL of the above dissolved solution B and 200uL of hydrazine hydrate, and stir After 1 min, add the remaining solution B above to solution A at a rate of 10 mL / min. After the addition, keep it warm at 160°C for 1 h;

[0058] (3) After cooling down, wash with water, wash with ethanol, and centrifuge to obtain silver nanowire 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com