Preparation method and application of novel modified amine epoxy curing agent

An amine epoxy and curing agent technology is applied in the field of preparation of a new type of modified amine epoxy curing agent, which can solve the problems of poor molecular structure designability and high formaldehyde content of the curing agent, and can improve the high free formaldehyde content and control the formaldehyde content. , the effect of promoting the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In a three-necked flask equipped with a mechanical stirrer, a condenser, and a thermometer, 18.82 g (0.2 mol) of phenol, 13.2 g (0.44 mol) of paraformaldehyde, and 200 mL of toluene were sequentially added, and the temperature was slowly raised to 55° C. in an oil bath; then At intervals of 15 minutes, add 20.44 g (0.2 mol) of N,N-dimethyl-1,3-diaminopropane in three batches. The mass fraction of the solute in the system is 30%. When N,N-dimethyl-1 , After adding all the 3-diaminopropane, slowly raise the temperature to 85°C, stir and react for 4 hours, wash and dry after the reaction, and obtain a light yellow product, namely benzoxazine P-dampa, whose structure is shown in formula (3) As shown, the yield is 92.7%.

[0040]

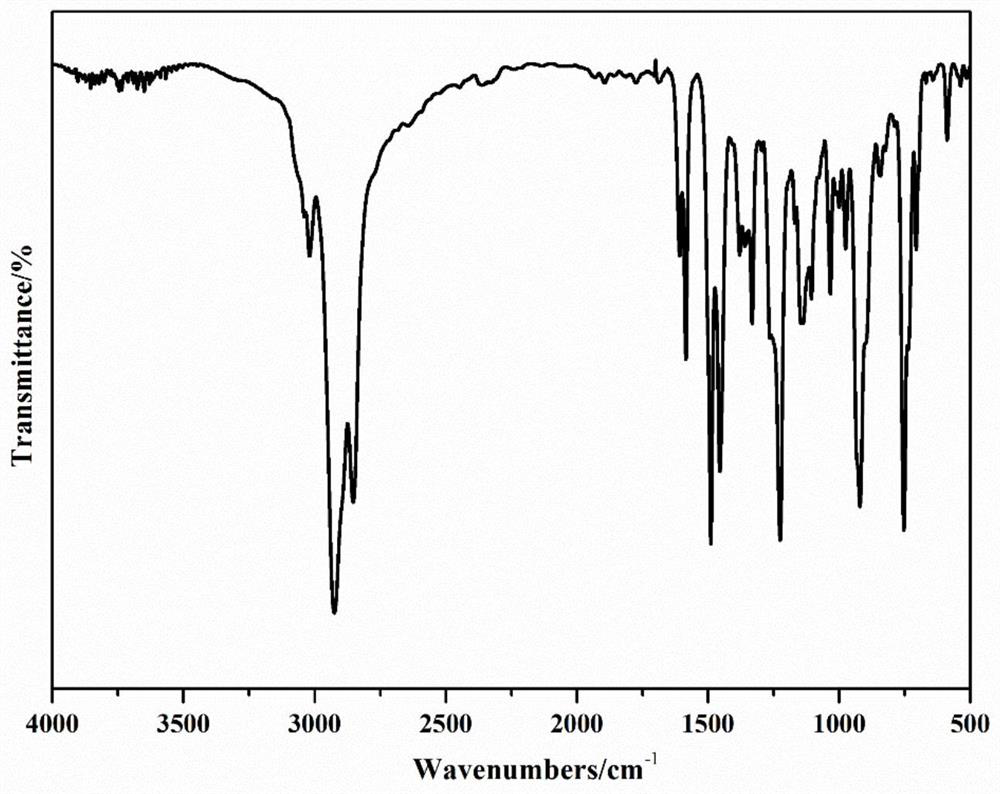

[0041] The prepared benzoxazine has carried out infrared spectroscopic analysis, and the results are as follows: figure 1 shown. As can be seen from the figure, the 921cm -1 Is the characteristic absorption peak of oxazine ring, 1034cm -1 a...

Embodiment 2

[0043] In a three-neck flask equipped with magnetic stirring, a condenser, and a thermometer, 4.42 g (0.02 mol) of benzoxazine P-dampa and 2.33 g (0.02 mol) of hexamethylenediamine prepared in Example 1 were added successively, and in a solvent-free 1. Under the condition of nitrogen protection, put it in an oil bath and slowly raise the temperature to 90° C., and stir for 5 hours to obtain curing agent-I (①), whose structure is shown in formula (4), and the yield is 95.6%.

[0044]

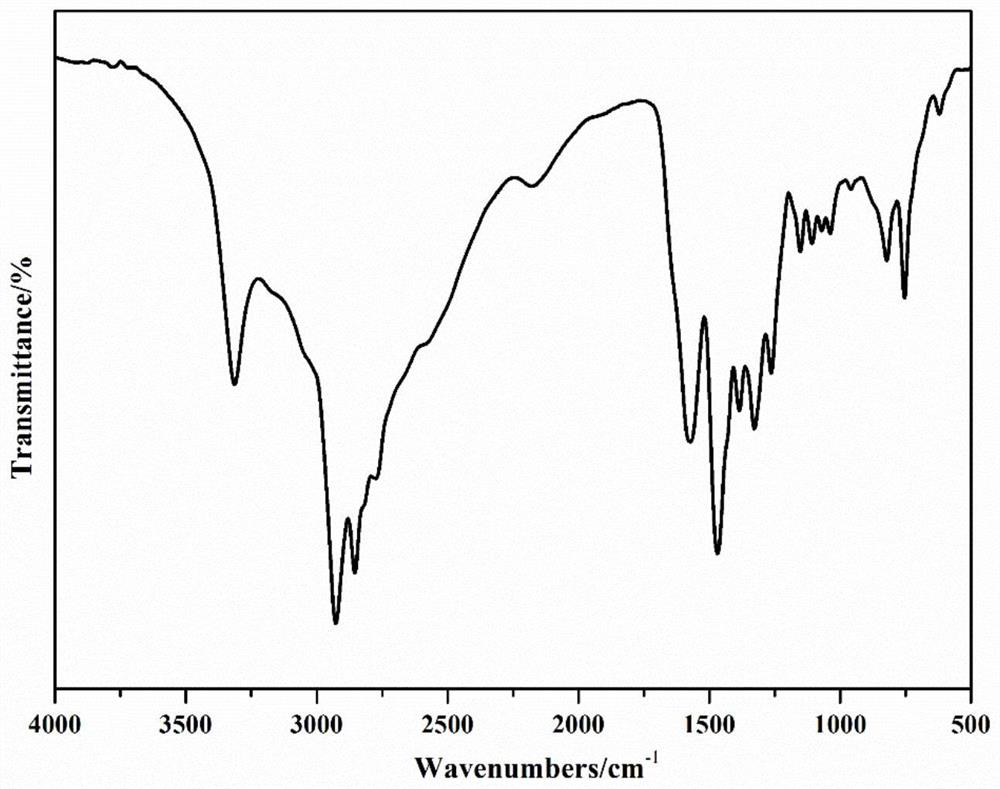

[0045] Prepared curing agent-I has carried out infrared spectroscopic analysis, and the results are as follows: figure 2 shown. As can be seen from the figure, the 921cm -1 The characteristic peak of the oxazine ring disappeared, 3313cm -1 There is an absorption peak of -OH at 1137cm -1 There is a C-N-C vibration peak at 1381cm -1 -CH 3 vibration peak. Therefore, it can be shown that the synthesized compound has the correct structure.

Embodiment 3

[0047] In the there-necked flask equipped with magnetic stirring, condenser, and thermometer, benzoxazine P-dampa 4.42g (0.02mol) and triethylenetetramine 2.92g (0.02mol) prepared in Example 1 were added successively. Under the conditions of solvent and nitrogen protection, put it in an oil bath and slowly raise the temperature to 100°C, and stir for 4 hours to obtain curing agent-II (②), whose structure is shown in formula (5), and the yield is 98.1%.

[0048]

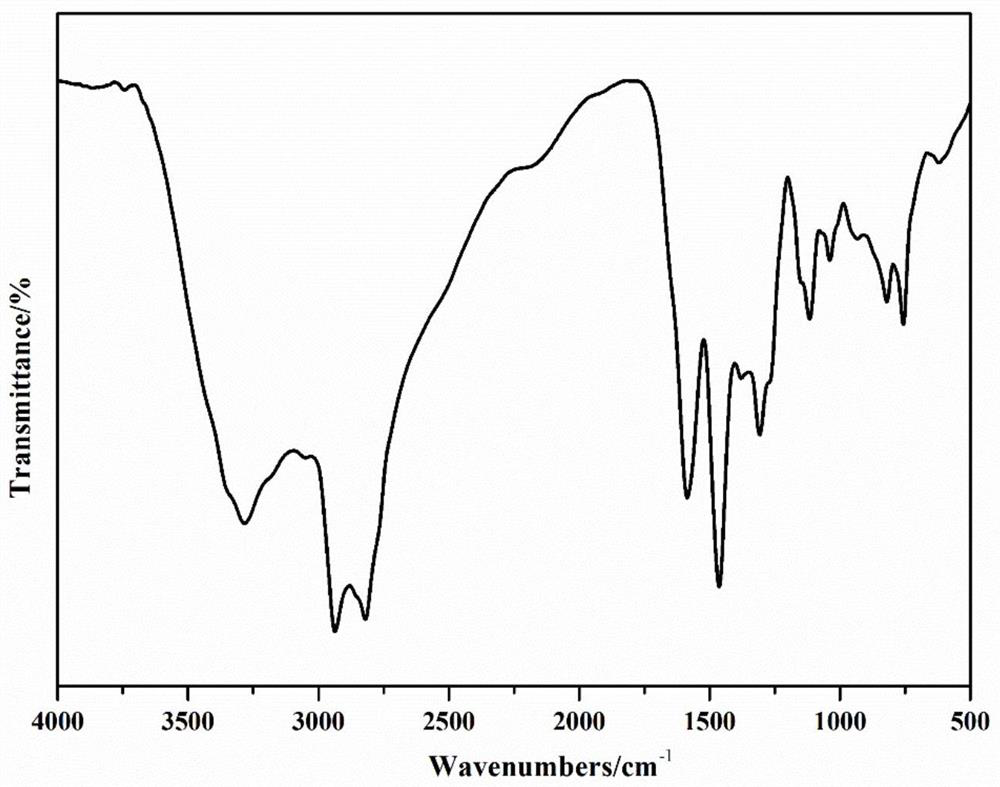

[0049] Prepared curing agent-II has carried out infrared spectroscopic analysis, and the results are as follows: image 3 shown. As can be seen from the figure, the 921cm -1 The characteristic peak of the oxazine ring disappeared, 3282cm -1 There is an absorption peak of -OH at 1117cm -1 There is a C-N-C vibration peak at 1380cm -1 -CH 3 vibration peak. Therefore, it can be shown that the synthesized compound has the correct structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gelation time | aaaaa | aaaaa |

| Gelation time | aaaaa | aaaaa |

| Gelation time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com