Porous polymer-sulfur composite material, preparation method and application thereof

A porous polymer and polymer technology, applied in the direction of active material electrodes, structural parts, positive electrodes, etc., can solve the problems of increasing material and battery costs, increasing battery energy density, complex post-processing, etc., and achieve excellent cycle stability, Effect of suppressing shuttling and high Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] (1) Preparation of porous polymer

[0092] Monomer I is an aldehyde monomer, R 1 with R 2 All are H, n=1

[0093] Monomer II is an amine monomer, R 3 for H, R 4 for-SO 3 H,n=1

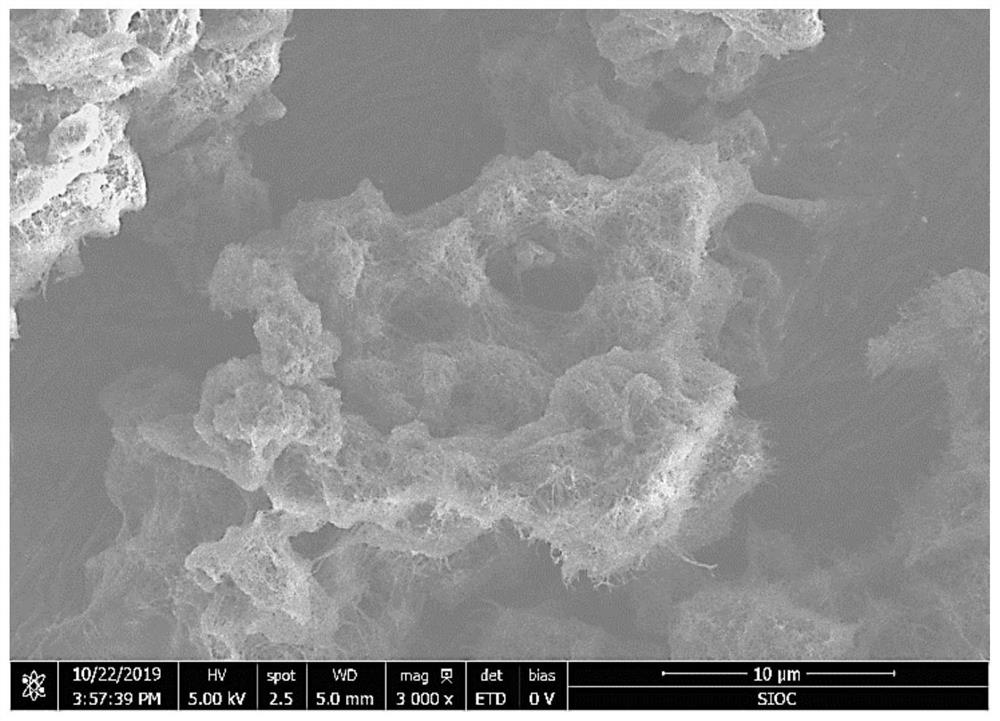

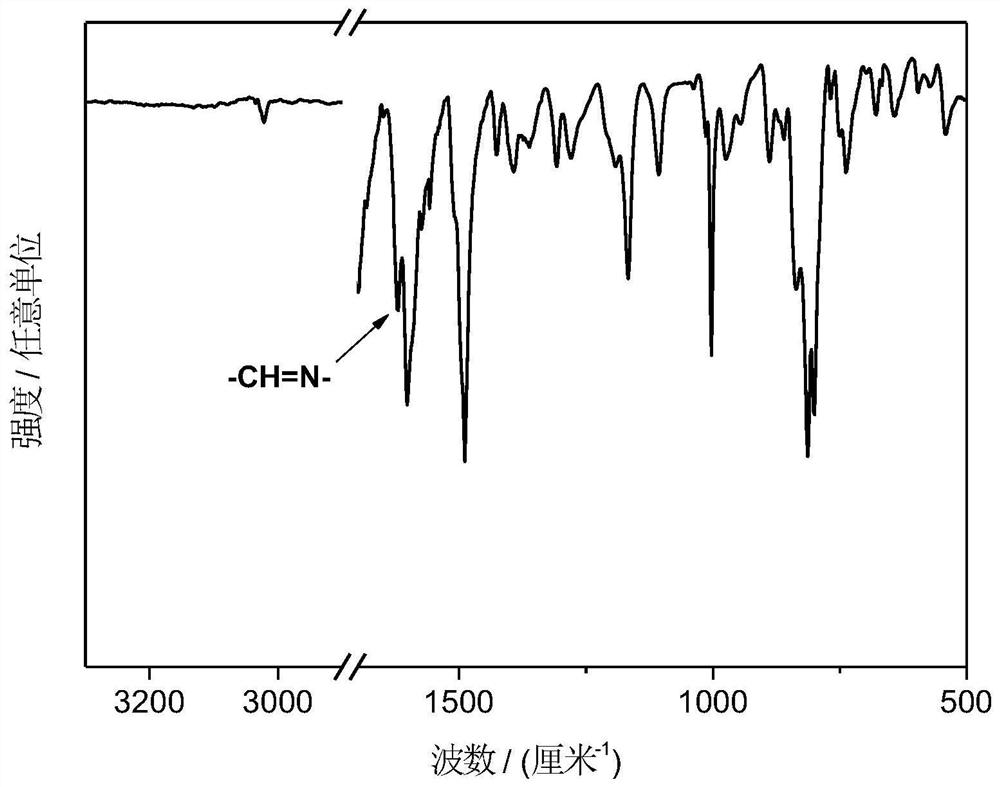

[0094] The monomer I and the monomer II are weighed according to the molar ratio of 1:1, dispersed in the mixed solvent of butanol, dichlorobenzene and acetic acid with a volume ratio of 2:4:1, sealed tube and vacuumized 5℃min -1 The temperature was raised to 120° C., and the insulation reaction was carried out for 72 hours to obtain a porous polymer ( figure 1 ). Combined with the infrared spectrum ( figure 2 ) analysis, it is not difficult to find that monomer I reacts with monomer II to form an imine bond to obtain a porous polymer. The specific surface area of the resulting porous polymer is 500 m 2 g -1 , with a pore volume of 0.9 cm 3 g -1 , the pore size is 1.4nm.

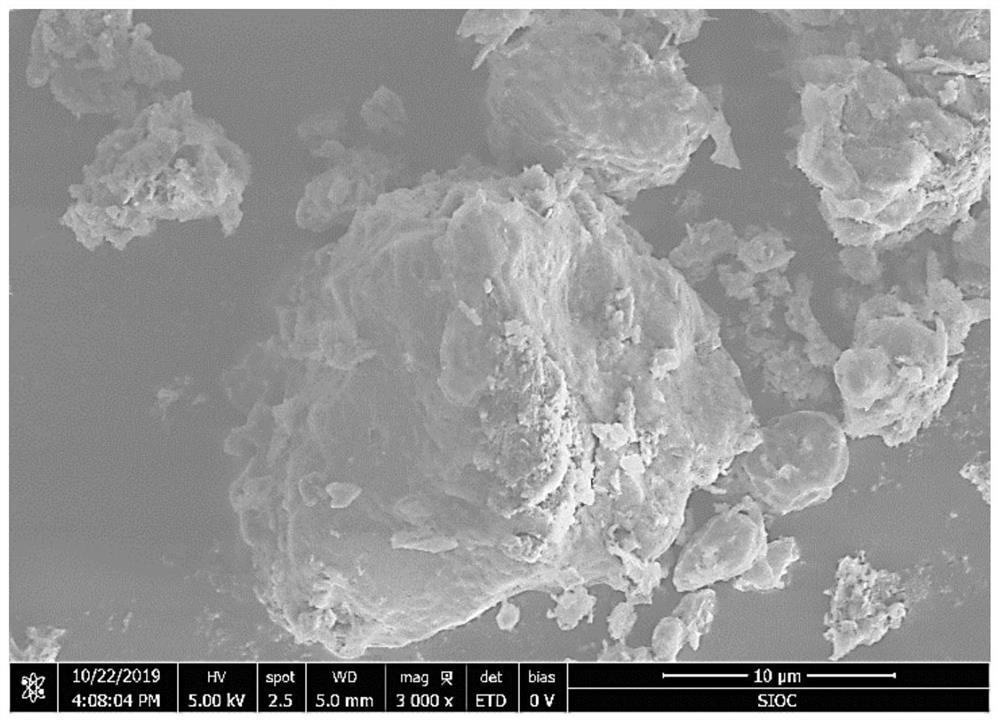

[0095] (2) Preparation of porous polymer-sulfur composites

[0096] The above-mentioned porous poly...

Embodiment 2

[0103] Other is identical with embodiment 1, difference is:

[0104] R in monomer I 1 for R 2 for H, n=1

[0105] R in monomer II 3 for H, R 4 for-SO 3 H,n=1

[0106] The specific surface area of the obtained porous polymer is 620m 2 g -1 , the pore volume is 0.85cm 3 g -1 , the pore size is 1.2nm; the mass percentage of sulfur in the porous polymer-sulfur composite material is about 70%.

[0107] The obtained lithium-sulfur battery is subjected to the same test method as in Example 1, and the 0.1C discharge specific capacity is 1608mAh g -1 , the discharge specific capacity after 50 cycles is 882mA h g -1 .

Embodiment 3

[0109] Others are the same as Example 1, the difference is:

[0110] Monomer IR 1 for R 2 for H, n=1

[0111] R in monomer II 3 for H, R 4 for-SO 3 H, n=2

[0112] The specific surface area of the resulting porous polymer is 570 m 2 g -1 , the pore volume is 0.96cm 3 g -1 , the pore size is 1.3nm; the mass percentage of sulfur in the porous polymer-sulfur composite is about 77%.

[0113] The obtained lithium-sulfur battery is subjected to the same test method as in Example 1, and the 0.1C discharge specific capacity is 1614mAh g -1 , the discharge specific capacity after 50 cycles is 896mA h g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com