Ultrasonic-assisted laser welding method for steel wheel rim

An ultrasonic-assisted, laser welding technology, applied in the field of wheel welding manufacturing, can solve the problems of high-power lasers being expensive, reducing the mechanical properties of the joints, and reducing the elongation at the joints. The effect of laser power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

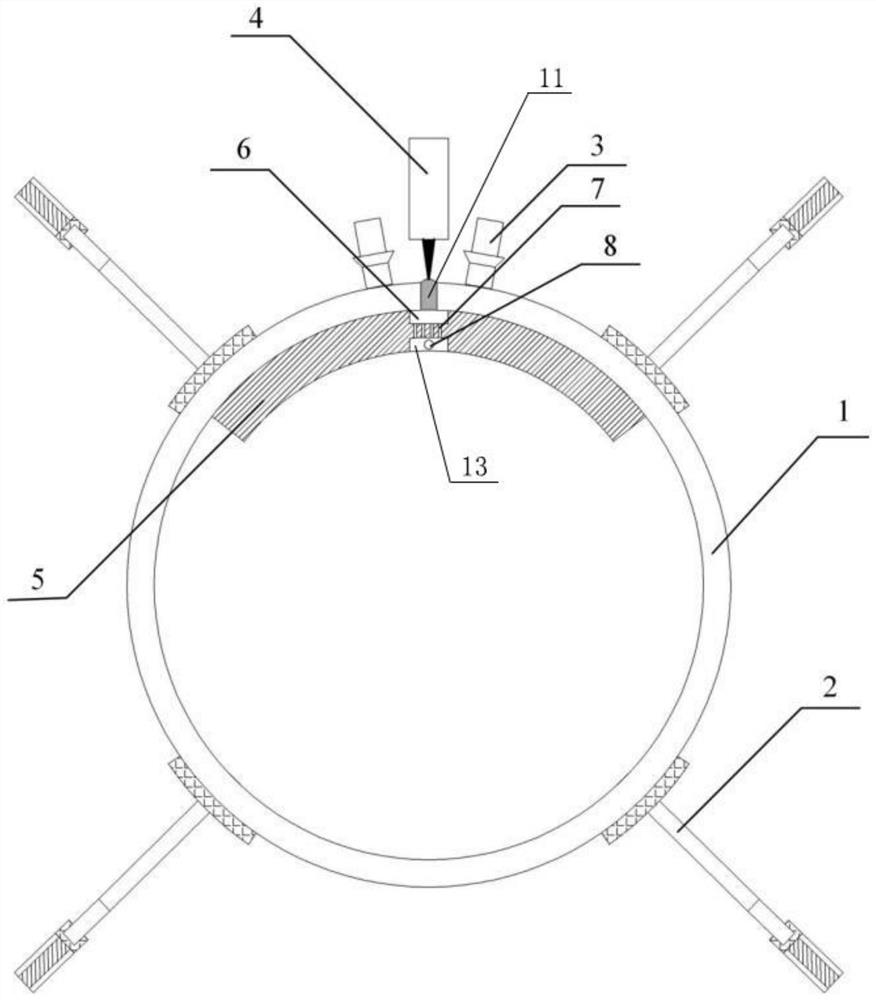

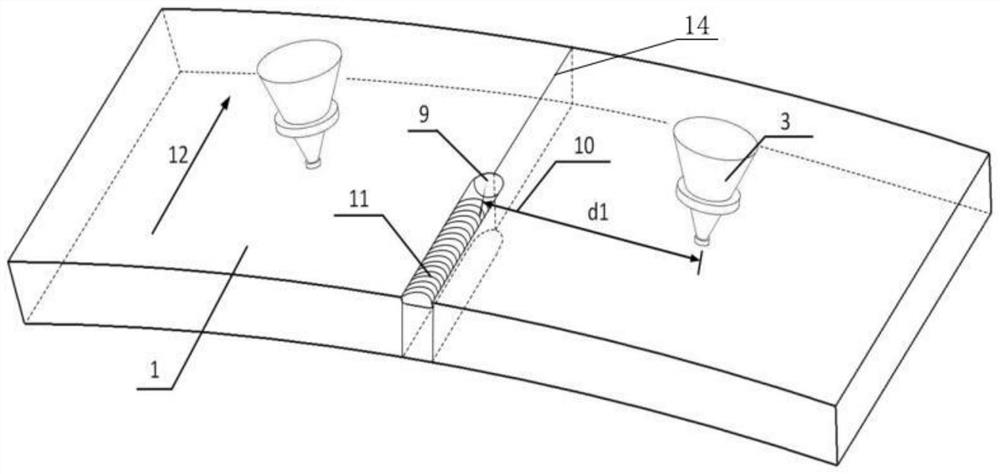

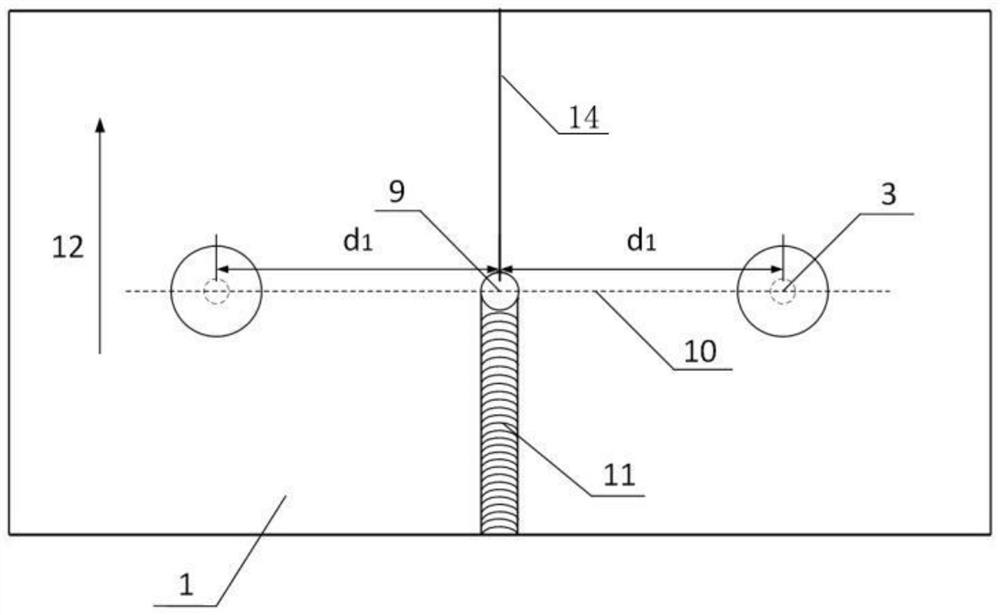

[0029] In order to clearly illustrate the technical features of the present solution, the present solution will be described below through specific embodiments and in conjunction with the accompanying drawings.

[0030] An ultrasonic-assisted laser welding method for a steel wheel rim comprises the following steps.

[0031] (1) Grinding, cleaning and rolling the steel plate to be welded.

[0032] The steel plate is medium carbon high-quality non-alloy steel, low-alloy steel or hot-formed steel, the thickness of the steel plate is 2-15mm, preferably the steel plate is made of 22MnB5 hot-formed steel, the thickness of the preferred steel plate is 5mm, and the steel plate is soaked in a tank before welding. The steel plate is immersed in an acid solution, and after removing rust and oxide scale, the pickled steel plate is washed with water to clean the acid solution and residues on the surface of the steel plate, and the washed steel plate is passivated by soaking in a tank. An ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap