Method for extracting citrus pectin by using compound enzyme

A compound enzyme method and compound enzyme technology, which is applied in the field of food production and extraction technology, can solve the problems of high requirements for extraction equipment and large environmental pollution, and achieve the effects of low pollution, low energy consumption and good rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, single enzymatic method extracts the yield of citrus pectin

[0032] According to the suitable temperature and pH range of cellulase, xylanase and acid protease, the single factor experiment was carried out with pectin yield as the reference index, and the enzyme addition amount was studied separately. The mass of the pretreated citrus peel powder was: fiber Sulfase (1%, 2%, 3%, 4%, 5%, 6%, 7%, 8%), xylanase (1%, 3%, 5%, 7%, 9%, 11% , 13%) and acid protease (1%, 1.5%, 2%, 2.5%, 3%), the solid-liquid ratio is (10mL / g, 15mL / g, 20mL / g , 25mL / g, 30mL / g), enzymatic hydrolysis time (1h, 2h, 3h, 4h, 5h, 6h), temperature (40°C, 45°C, 50°C, 55°C, 60°C) and pH (3.5, 4.0 , 4.5, 5.0, 5.5) The impact of these five factors on the yield of pectin.

[0033] 1. Pretreatment of citrus peels: Boil fresh citrus peels in boiling water for 10 minutes to inactivate the proenzyme, then rinse with flowing water for 3 times to remove part of the orange peel pigment. The treated ...

Embodiment 2

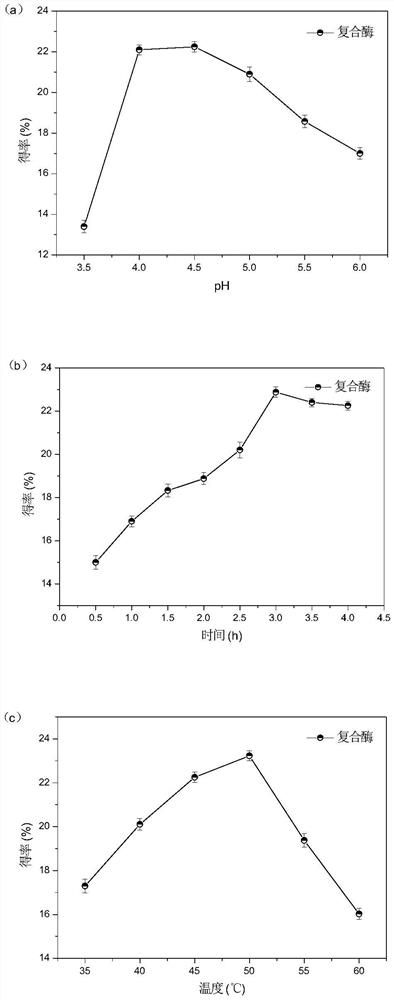

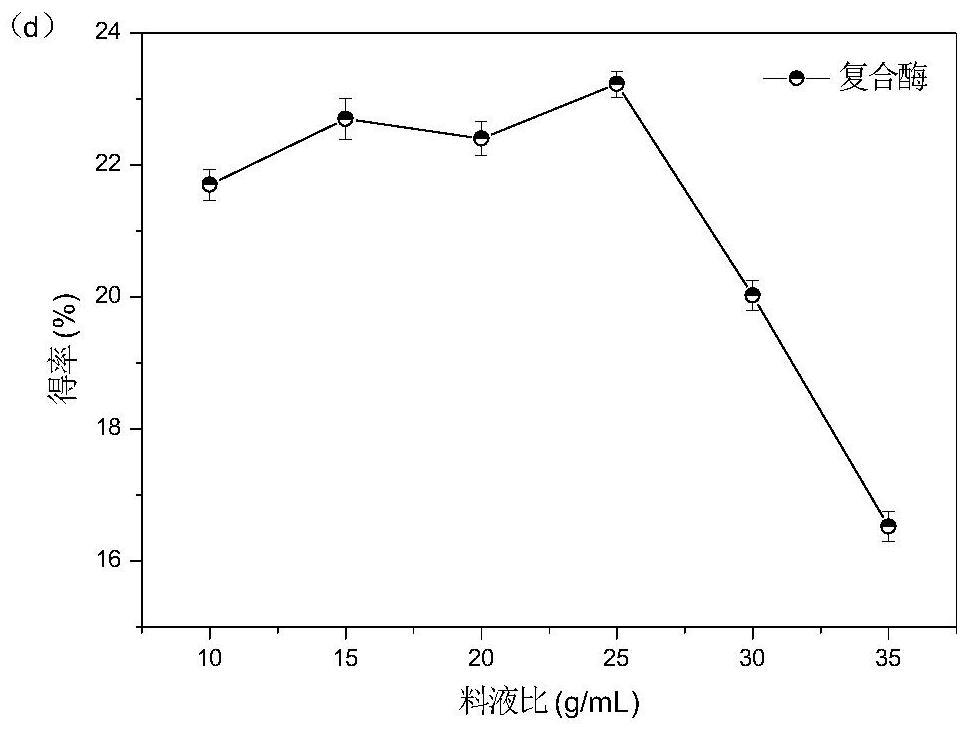

[0047] Embodiment 2, compound enzyme method extracts citrus pectin single factor experiment

[0048] (1)pH

[0049] Weigh 10 g of citrus peel powder after pretreatment by the method of Example 1, mix it with water at a material-to-liquid ratio of 25 mL / g, adjust to different pHs (3.5, 4.0, 4.5, 5.0, 5.5, 6.0), and heat up to 50 ° C , add 0.6g cellulase, 1g xylanase and 0.2g acid protease, and react uniformly in a constant temperature magnetic stirrer at 450rpm for 3h. Immediately after the reaction, boil to inactivate the enzyme activity. After cooling to normal temperature, centrifuge the pectin extract at 4°C and 10,000rpm for 10min to remove the orange peel and pomace sediment at the bottom, and filter the supernatant through a 200-mesh screen. Concentrate under pressure to 25% of the volume of the supernatant, pour 1.5 times the volume of ethanol and let stand for precipitation for 2 hours to precipitate pectin substances, filter through a 200-mesh sieve to obtain floccul...

Embodiment 3

[0058] Example 3, Response Surface Optimal Design of Compound Enzyme Extraction Process

[0059] Taking the yield of citrus pectin as the response value to compare, on the basis of the single factor test results of the compound enzyme, taking the solid-liquid ratio (A), temperature (B), pH (C) and time (D) as the investigation objects, the Response surface optimization experiments. See Table 3 for the factor level table.

[0060] Table 3 Factors and levels of response surface design experiments

[0061]

[0062] Orthogonal experiments are carried out according to Table 3, and the experimental results are shown in Table 4.

[0063] Table 4 The specific scheme and results of the response surface design experiment

[0064]

[0065]

[0066] In this experiment, Design Expert 8.0.6 software was used to organize and analyze the test results, and the data in Table 4 were fitted with quadratic polynomials, and the quadratic multiple regression model was obtained as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com