High-contrast high-definition lens and preparation method thereof

A high-definition, high-contrast technology, applied in the field of optical lenses, can solve the problems of poor dispersion and compatibility, and achieve the effects of improving compatibility and dispersion, increasing contrast, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

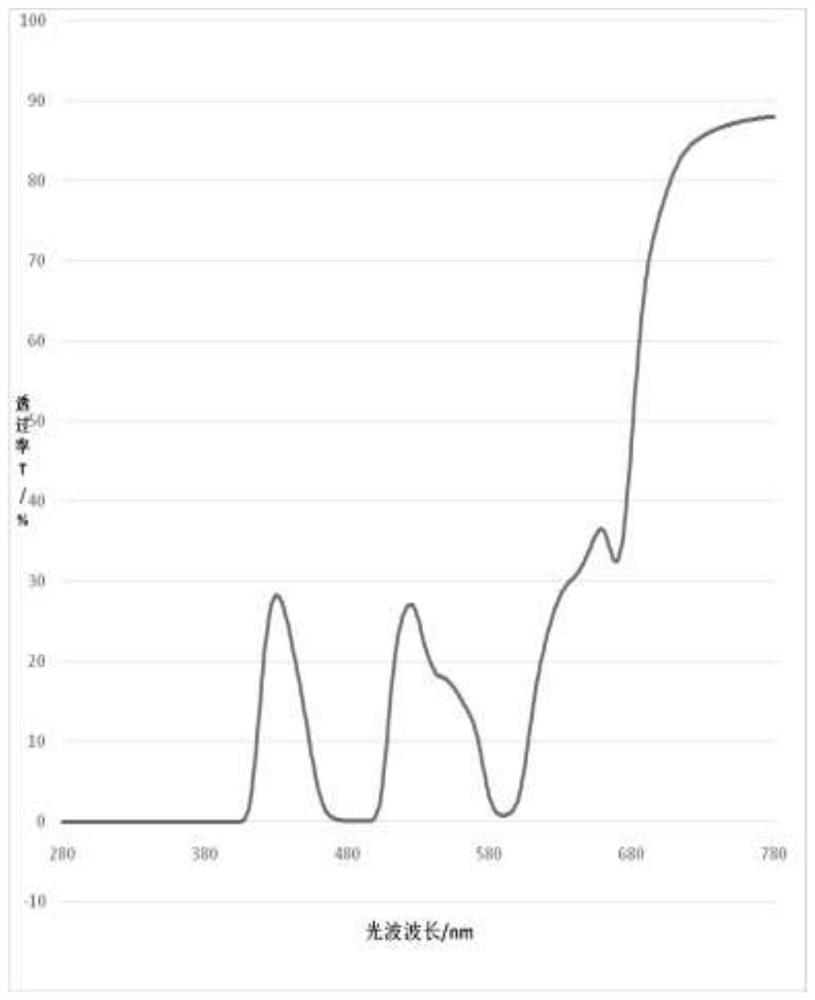

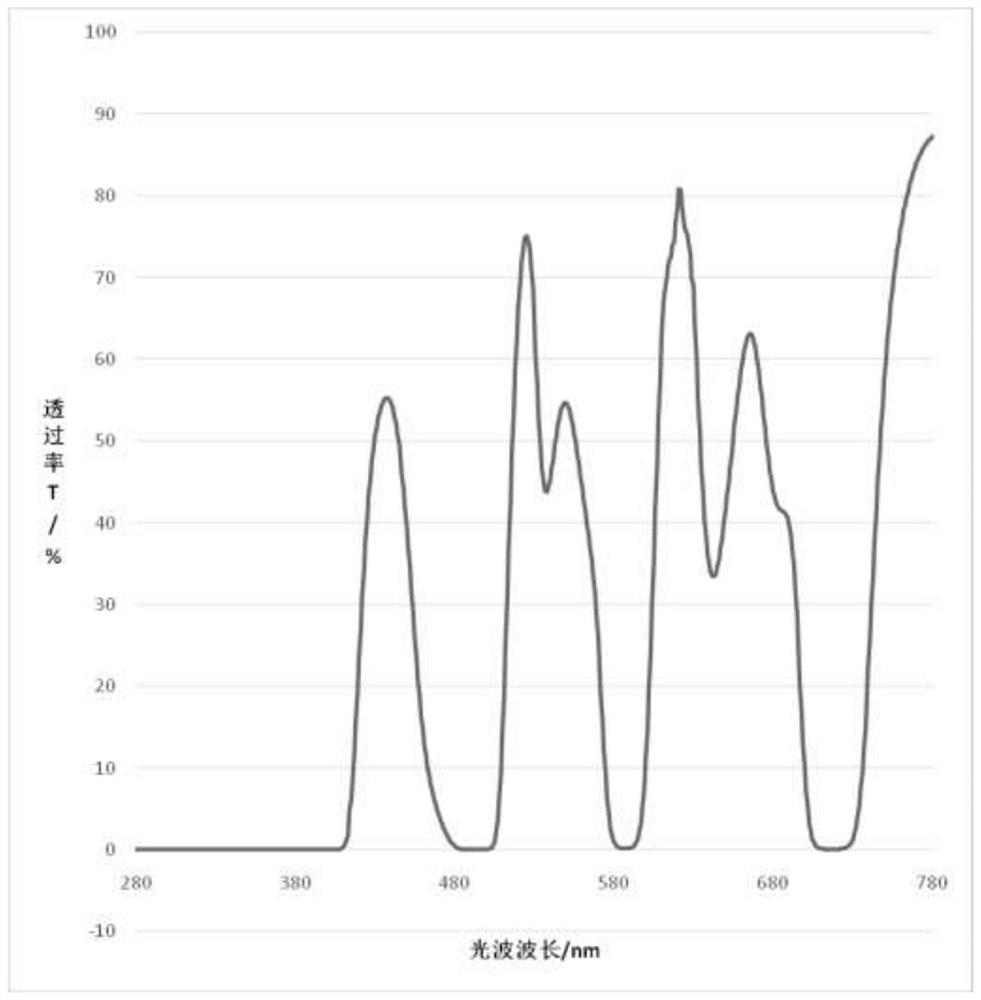

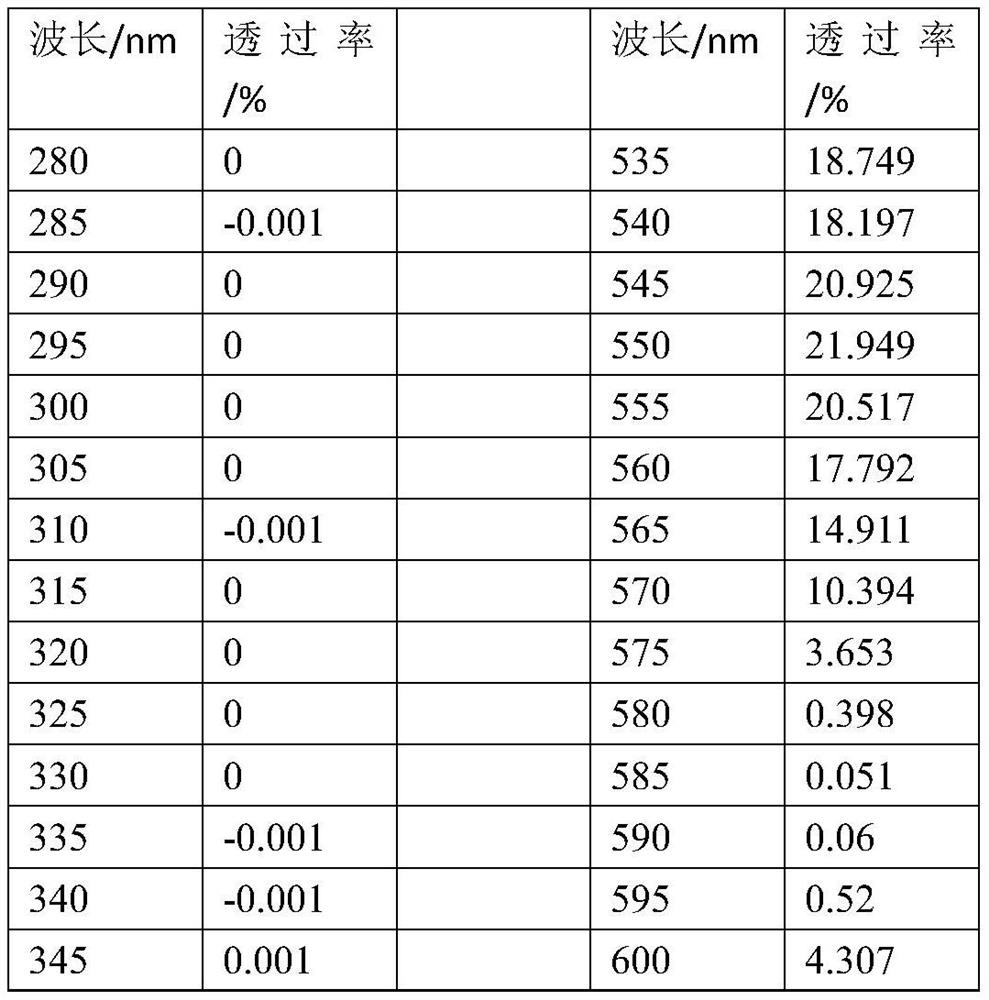

Image

Examples

Embodiment 1

[0043] A high-contrast high-definition lens, comprising a cured film layer slurry, a mixed solution 1 and a base, wherein, calculated in parts by weight, the mixed solution 1 and the cured film layer slurry jointly include the following components: bisphenol A epoxy acrylic resin 40 parts of dioctyl adipate, 10 parts of dioctyl adipate, 10 parts of vinyltrimethoxysilane, 0.3 parts of tetrabutylammonium chloride, 3 parts of praseodymium oxide, 3 parts of neodymium oxide, 2 parts of azo nickel metal compound, three 10 parts of ethylhexyl phosphoric acid, 5 parts of octadecyl dimethyl benzyl ammonium chloride, 0.1 part of simethicone, 20 parts of ethyl benzoate, 5 parts of polyethylene glycol and 15 parts of acrylic resin.

[0044] The preparation method of cured film layer slurry and mixed solution 1 comprises the following steps:

[0045] S1. Mix and stir bisphenol A epoxy acrylic resin, triethylhexyl phosphoric acid, dioctyl adipate and vinyltrimethoxysilane evenly to obtain a...

Embodiment 2

[0057] A high-contrast high-definition lens, comprising a cured film layer slurry, a mixed solution 1 and a base, wherein, calculated in parts by weight, the mixed solution 1 and the cured film layer slurry jointly include the following components: bisphenol A epoxy acrylic resin 40 parts of dioctyl adipate, 10 parts of dioctyl adipate, 10 parts of vinyltrimethoxysilane, 0.3 parts of tetrabutylammonium chloride, 3 parts of praseodymium oxide, 3 parts of neodymium oxide, 2 parts of nickel azo metal compound, three 10 parts of ethylhexyl phosphoric acid, 5 parts of octadecyldimethylbenzyl ammonium chloride, 0.1 part of dimethylsilane, 20 parts of ethyl benzoate, 5 parts of polyethylene glycol and 15 parts of acrylic resin.

[0058] The preparation method of cured film layer slurry and mixed solution 1 comprises the following steps:

[0059] S1, bisphenol A epoxy acrylic resin, triethylhexyl phosphoric acid, dioctyl adipate and vinyltrimethoxysilane are mixed and stirred evenly t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com