Burkholderia gladioli A1-07 and application thereof

A technology of Burkholderia Populus and Holderella, which is applied in the field of microorganisms, can solve problems such as large acid-base wastewater, and achieve the effects of high production efficiency, good industrial application prospects and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

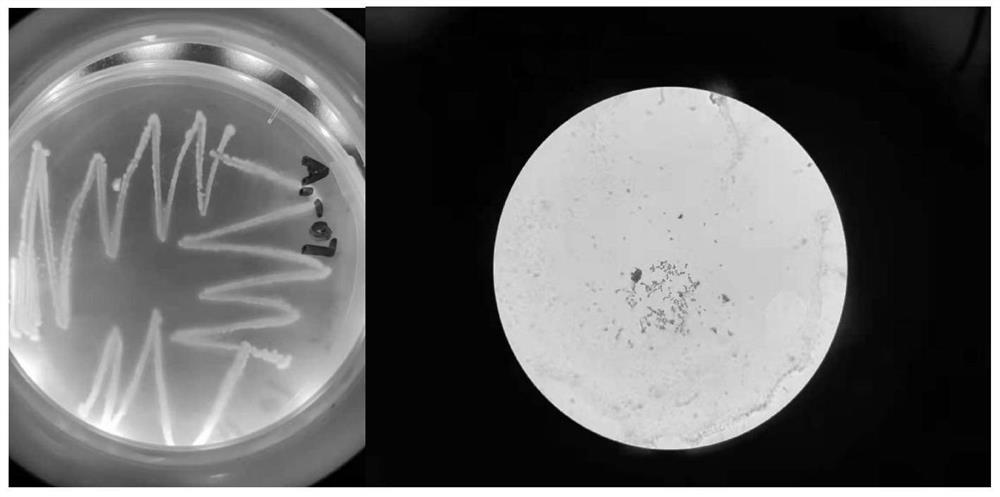

Embodiment 1

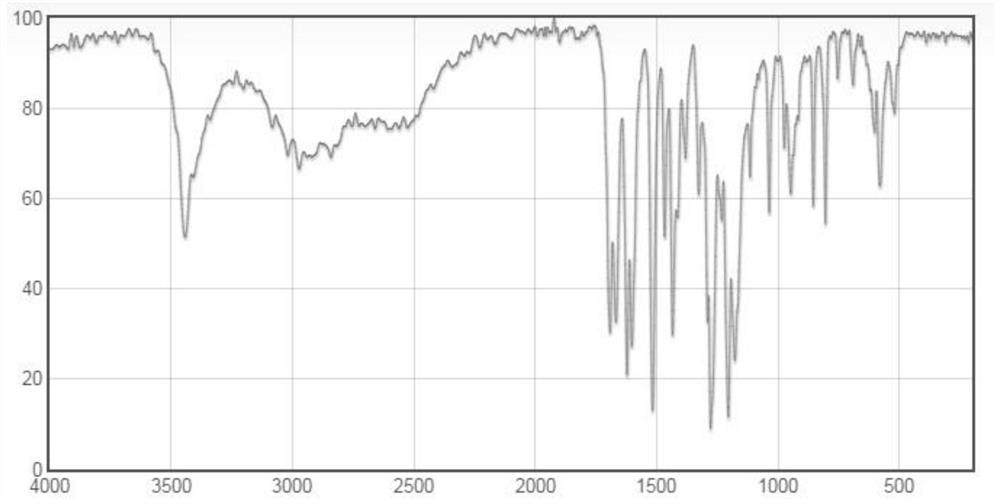

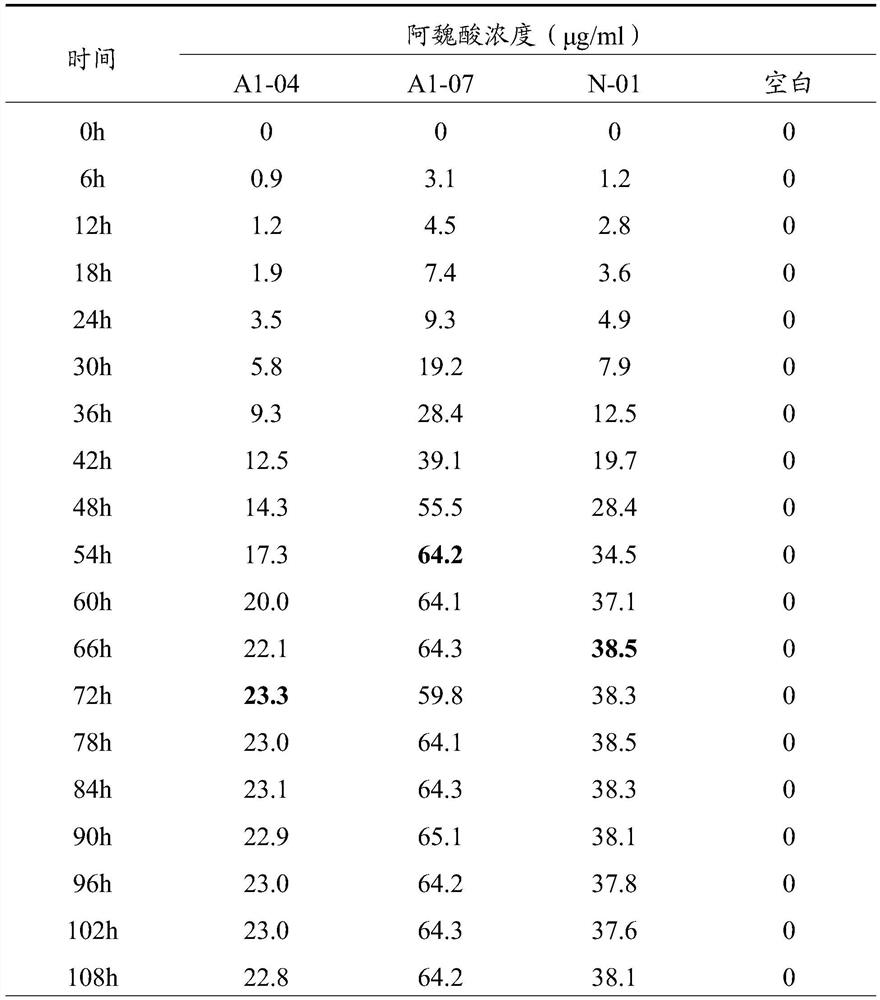

[0116] Embodiment 1: the present invention prepares ferulic acid by oryzanol

[0117] The implementation steps of this embodiment are as follows:

[0118] A. Preparation of crude enzyme powder

[0119] Preparation of liquid enzyme production medium: Weigh 10 parts by weight of glucose, 0.3 parts by weight of NaCl, 1.3 parts by weight of ammonium sulfate, 0.3 parts by weight of magnesium sulfate heptahydrate, and 0.3 parts by weight of dipotassium hydrogen phosphate, and then add 0.5 parts by weight of saturated oryzanol two Methyl sulfoxide solution, and then add them to 1000 parts by weight of distilled water to dissolve, and use 0.3N aqueous sodium hydroxide solution or 0.2N nitric acid aqueous solution to adjust the pH of the obtained uniform solution to 7.0, and then use sterilizing equipment at a temperature of 121 ° C Sterilize under 20min, obtain described liquid enzyme production medium;

[0120] Pick a single colony of Burkholderia gladiolus A1-07 and inoculate it i...

Embodiment 2

[0127] Embodiment 2: the present invention prepares ferulic acid by oryzanol

[0128] The implementation steps of this embodiment are as follows:

[0129] A. Preparation of crude enzyme powder

[0130] Preparation of liquid enzyme production medium: Weigh 10 parts by weight of glucose, 0.3 parts by weight of NaCl, 1.3 parts by weight of ammonium sulfate, 0.3 parts by weight of magnesium sulfate heptahydrate, and 0.3 parts by weight of dipotassium hydrogen phosphate, and then add 0.5 parts by weight of saturated oryzanol two Methyl sulfoxide solution, and then add them to 1000 parts by weight of distilled water to dissolve, and use 0.4N potassium hydroxide aqueous solution or 0.3N hydrochloric acid aqueous solution to adjust its pH to 7.0, and then use sterilizing equipment at a temperature of 121 ° C Sterilize under 20min, obtain described liquid enzyme production medium;

[0131] Pick a single colony of Burkholderia gladiolus A1-07 and inoculate it into the liquid enzyme-pr...

Embodiment 3

[0138] Embodiment 3: the present invention prepares ferulic acid by oryzanol

[0139] The implementation steps of this embodiment are as follows:

[0140] A. Preparation of crude enzyme powder

[0141] Preparation of liquid enzyme production medium: Weigh 10 parts by weight of glucose, 0.3 parts by weight of NaCl, 1.3 parts by weight of ammonium sulfate, 0.3 parts by weight of magnesium sulfate heptahydrate, and 0.3 parts by weight of dipotassium hydrogen phosphate, and then add 0.5 parts by weight of saturated oryzanol two Methyl sulfoxide solution, and then add them to 1000 parts by weight of distilled water to dissolve, and use 0.1N sodium carbonate aqueous solution or 0.1N sulfuric acid aqueous solution to adjust the pH of the obtained uniform solution to 7.0, and then use sterilizing equipment at a temperature of 121 ° C Sterilize for 20 minutes to obtain the liquid enzyme-producing medium;

[0142] Pick a single colony of Burkholderia gladiolus A1-07 and inoculate it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com