Shadow mask for patterned vapor deposition of organic light emitting diode (OLED) material, shadow mask module comprising same and method for manufacturing shadow mask module

A technology of light-emitting diodes and patterning, which is applied to photosensitive materials used in optomechanical equipment, photoplate-making process of pattern surface, metal material coating process, etc., which can solve alignment and alignment errors, inhomogeneity, Solve problems such as film bending, achieve high yield, reliable manufacturing process, and enhance mechanical strength and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

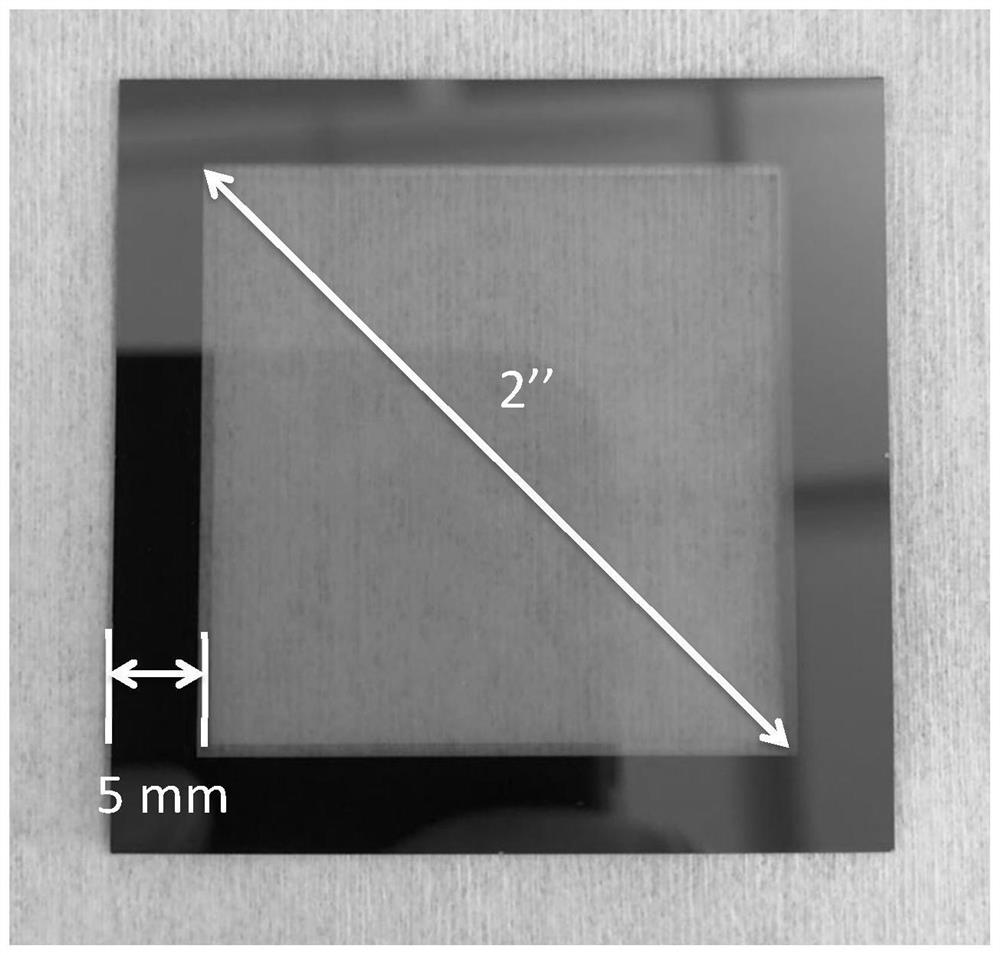

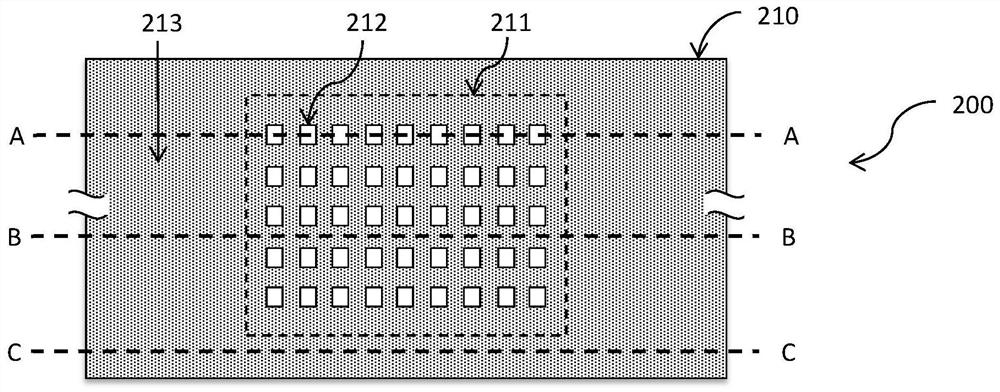

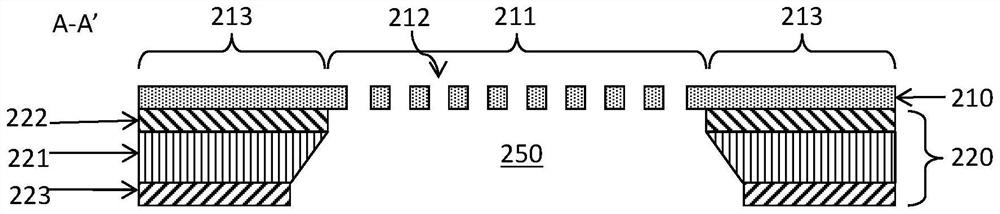

[0055] In this embodiment, the fabrication process of a shadow mask according to the structure disclosed in the disclosed method is described.

[0056] A 4-inch double-sided polished silicon wafer with a thickness of 400 μm was used as a starting substrate to fabricate a shadow mask. Sequentially use deionized water and 120°C sulfuric acid solution (sulfuric acid H 2 SO 4 / hydrogen peroxide H 2 o 2 =10 / 1) After cleaning, the wafer was immersed in a hydrofluoric acid (HF) solution at room temperature for 1 minute to remove native oxide. The wafer is then transferred to a furnace where both sides of the wafer are grown at a temperature of 1000°C of silicon oxide (SiOx). The silicon oxide on one side of the wafer is removed by an oxide etchant. The other side of the wafer that still has silicon oxide on it is defined as the front side, while the side without silicon oxide is defined as the back side. Next, 1.5 μm silicon nitride (SiN x ). Photoresist was then spin-coate...

Embodiment 2

[0058] A shadow mask was produced in the same manner as in Example 1, except that the thickness of the silicon oxide layer was instead of

Embodiment 3

[0060] A shadow mask was produced in the same manner as in Example 1, except that the thickness of the silicon oxide layer was instead of

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com