Gemstone inlaying process

A mosaic technology, gemstone technology, applied in jewelry, epoxy resin glue, adhesive type, etc., to achieve the effect of clean stone surface, improved mosaic efficiency, and improved data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A jewel inlay process, comprising the steps of:

[0037] 1) Turning stone position: under a magnifying glass, trim the stone position of the molded copper embryo or the injected wax mold by means of an electric drill;

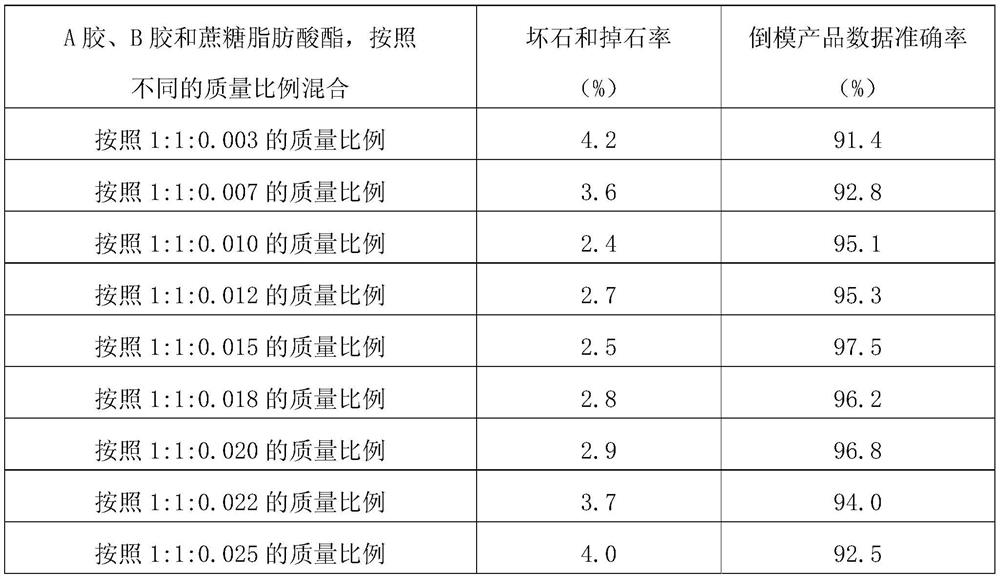

[0038] 2) Glue application: apply a layer of transparent epoxy resin AB glue and sucrose fatty acid ester mixture on the slot of the stone position obtained in the previous step, or when the stone position becomes slightly loose after part of the copper embryo is poured out , or when the size of the gemstones is slightly different, apply a layer of transparent epoxy resin AB glue and sucrose fatty acid ester mixture through the slot of the stone position, and then inlay the gemstones; the transparent epoxy resin AB glue and the mixture of sucrose fatty acid ester, wherein A glue, B glue and sucrose fatty acid ester are mixed according to the mass ratio of 1:1:0.015, and A glue (selected from Zhongxin brand 4-hour sticky stone glue A) is the main agent, ...

Embodiment 2

[0047] A jewel inlay process, comprising the steps of:

[0048] 1) Turning stone position: under a magnifying glass, use a gun to trim the stone position of the inverted copper embryo or injected wax model through a gun;

[0049] 2) Glue application: apply a layer of transparent epoxy resin AB glue and sucrose fatty acid ester mixture on the slot of the stone position obtained in the previous step, or when the stone position becomes slightly loose after part of the copper embryo is poured out , or when the size of the gemstones is slightly different, apply a layer of transparent epoxy resin AB glue and sucrose fatty acid ester mixture through the slot of the stone position, and then inlay the gemstones; the transparent epoxy resin AB glue and the mixture of sucrose fatty acid ester, wherein A glue, B glue and sucrose fatty acid ester are mixed according to the mass ratio of 1:1:0.01, and A glue (selected from Zhongxin brand 4-hour sticky stone glue A) is the main agent, B glu...

Embodiment 3

[0058] A jewel inlay process, comprising the steps of:

[0059] 1) Turning stone position: under a magnifying glass, trim the stone position of the molded copper embryo or the injected wax mold by means of an electric drill;

[0060] 2) Glue application: apply a layer of transparent epoxy resin AB glue and sucrose fatty acid ester mixture on the slot of the stone position obtained in the previous step, or when the stone position becomes slightly loose after part of the copper embryo is poured out , or when the size of the gemstones is slightly different, apply a layer of transparent epoxy resin AB glue and sucrose fatty acid ester mixture through the slot of the stone position, and then inlay the gemstones; the transparent epoxy resin AB glue and the mixture of sucrose fatty acid ester, wherein A glue, B glue and sucrose fatty acid ester are mixed according to the mass ratio of 1:1:0.02, and A glue (selected from Zhongxin brand 4-hour sticky stone glue A) is the main agent, B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com