Cleaning method for removing chromatic aberration on the back of sapphire single-polishing substrate

A sapphire substrate and sapphire technology, applied in the direction of cleaning methods using liquids, cleaning methods using tools, cleaning methods and utensils, etc., can solve problems such as uneven cleaning of the surface of sapphire substrates, and achieve excellent settlement performance and excellent surface The effect of high activity and dilution ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0026] This embodiment provides a cleaning method for removing chromatic aberration on the back of a sapphire single throw substrate, the steps are as follows:

[0027] S1: After the sapphire substrate is ground off the machine, use running water to rinse off the grinding sand on the surface, and then soak it in an alkaline cleaning agent with a pH of 12 for 25 minutes, and use a water gun to rinse off the floating sand and alkaline cleaning agent on the surface;

[0028] Wherein, the alkaline cleaning agent is composed of the following components by weight: 55% deionized water, 15% inorganic base, 12% chelating agent, 10% inorganic auxiliary, 6% organic base, and 2% organic auxiliary.

[0029] S2: Use a nylon brush to brush both sides of the sapphire substrate while spraying the active agent, and finally spray pure water to rinse off the active agent on the surface of the sapphire substrate and the nylon brush;

[0030] S3: After scrubbing the surface of the sapphire substrat...

Embodiment approach 2

[0038] This embodiment is substantially the same as Embodiment 1, and the only difference is:

[0039] In S1, the soaking time with alkaline cleaning agent is 30min.

[0040] After S5 and before S6, the polished surface of the sapphire substrate after single-side chemical polishing was also scrubbed with a 4-fold compressed wiper, and then the impurity deposits on the surface were rinsed with pure water.

[0041] Except for this, this embodiment is exactly the same as Embodiment 1, which is not repeated here.

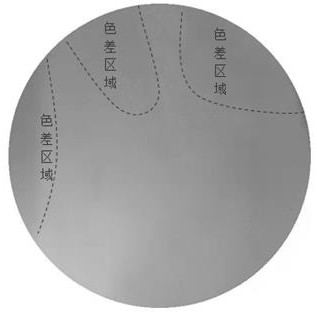

[0042] like figure 2 Shown is the appearance picture of the sapphire substrate obtained by using the methods of the above-mentioned Embodiments 1 and 2. It can be seen that figure 1 In contrast, the color difference on the back is significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com