Method for preparing low-cobalt positive electrode material by sol-gel-solid phase sintering method

A solid-phase sintering method and cathode material technology, which is applied in the field of C01G, can solve the problems affecting the crystal structure and electrical properties of low-cobalt or even cobalt-free cathode materials, uneven porous structure pore size, easy shrinkage and collapse, etc., to achieve excellent cycle Stability, elimination of local variability problem, effect of avoiding dust problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

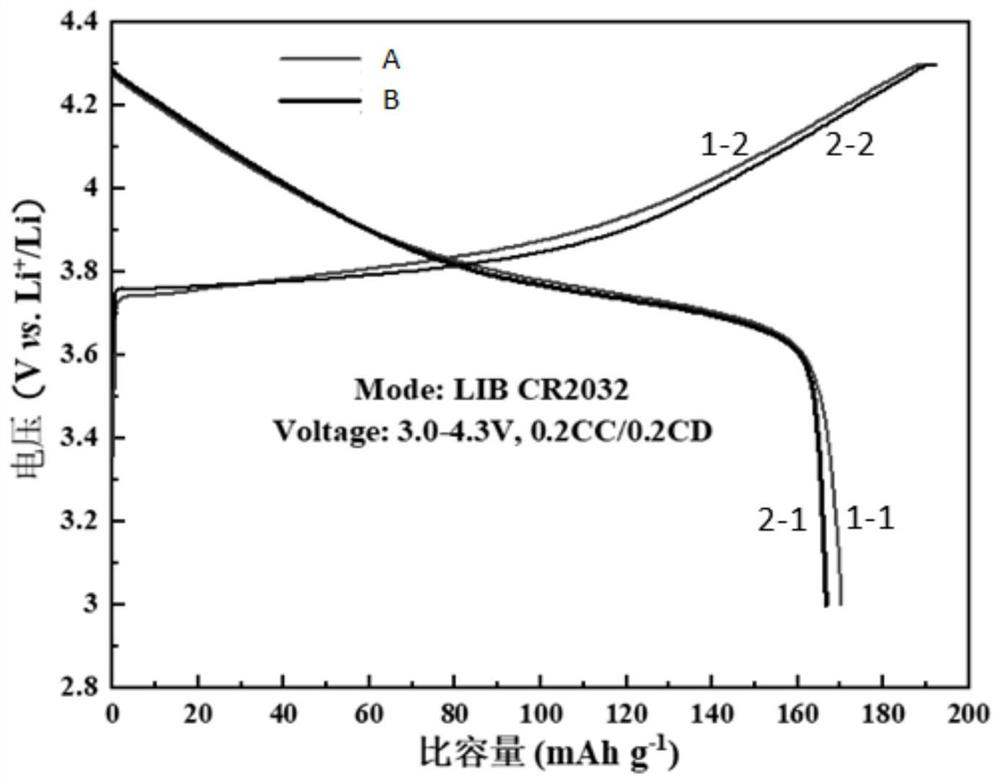

[0041] This example provides a method for preparing positive electrode materials, including:

[0042] Lithium salt sol preparation: take 35mL methanol, add 2.5mL lithium methoxide under stirring state, add 10mL water and 35mL tetrahydrofuran, mix, add 50mL tri-n-butyl borate at a rate of 20mL / h, stir for 30min, and obtain lithium salt sol ;

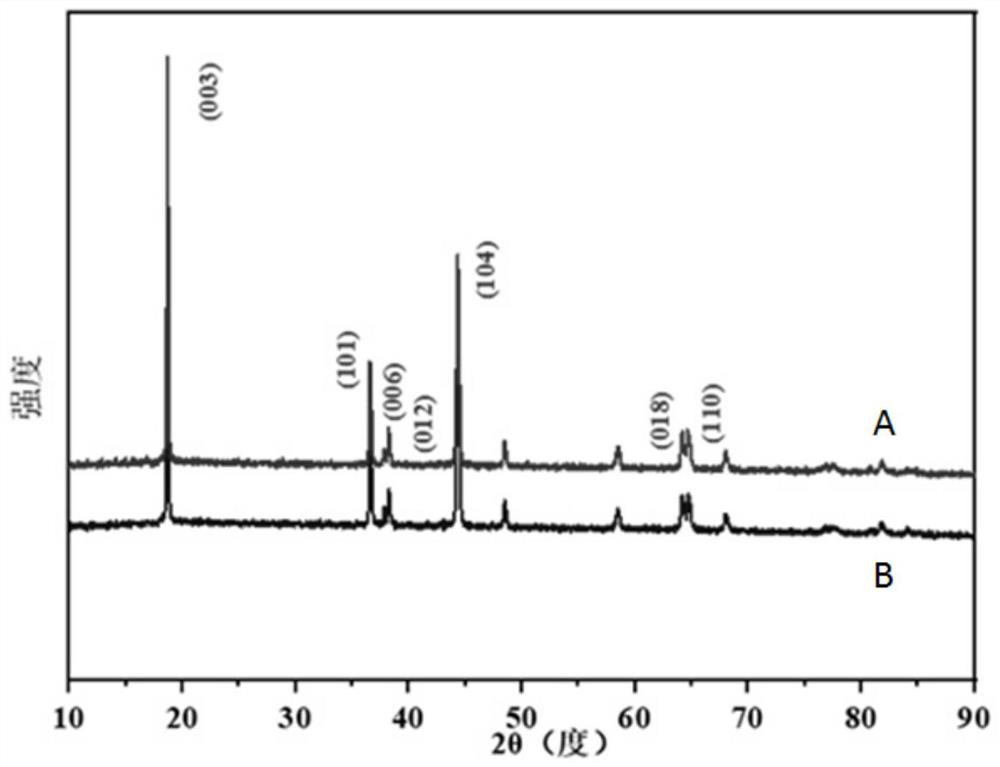

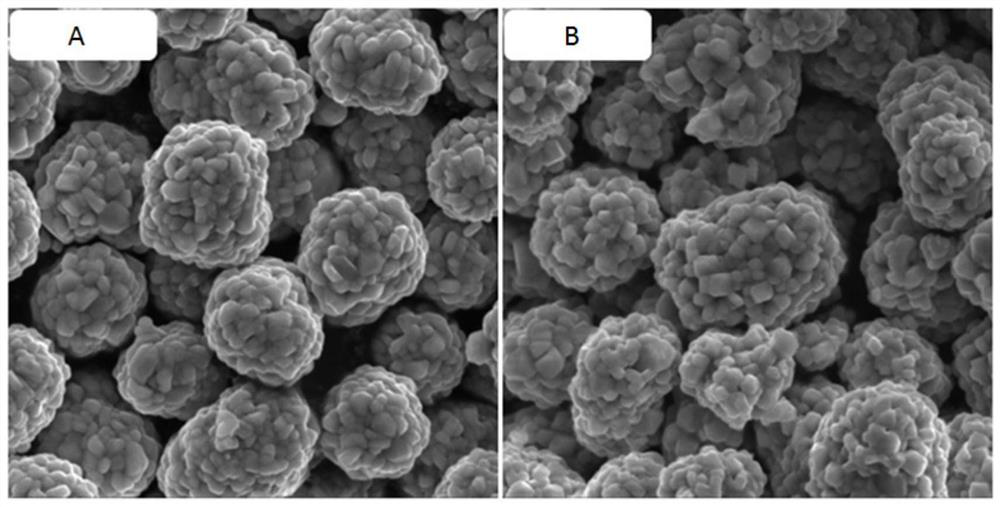

[0043] Preparation of low-cobalt precursor dispersion: take D prepared by batch co-precipitation method 50 3.5μm low cobalt ternary hydroxide precursor Ni 0.55 co 0.05 mn 0.40 (OH) 2 10.0 g was added to methanol, and stirred at 500 r / min for 2.5 h to obtain a low-cobalt precursor dispersion; the molar ratio of the lithium element in the lithium methoxide to the total moles of nickel, cobalt, and manganese in the precursor was 1.045:1;

[0044] Mixed gel preparation: Add the low-cobalt precursor dispersion into the lithium salt sol, stir at 300r / min for 4.0h, and store in a blast drying oven at 35°C for 12h to obtain a mixed gel;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com