Household waste incineration fly ash melting harmless co-treatment system

A domestic waste incineration and co-processing technology, which is applied in the direction of incinerators, gasification processes, combustion methods, etc., can solve problems such as high energy consumption, incomplete detoxification, and limited disposal volume, so as to enhance the degree of turbulence and improve the quality of waste Effect of burnout rate, savings on management and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

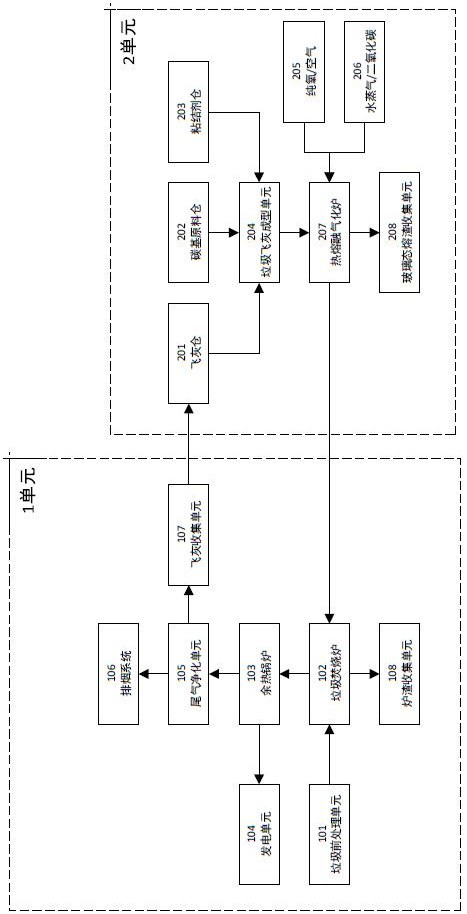

[0035] Such as figure 1 As shown, a system for harmless co-processing of domestic waste incineration fly ash melting and co-processing provided in this embodiment includes a waste incineration subsystem and a waste fly ash gasification melting harmless disposal subsystem. The waste incineration subsystem will collect The fly ash is transported to the garbage fly ash gasification melting harmless disposal subsystem for gasification melting harmless treatment.

[0036] The waste incineration subsystem includes a waste pretreatment unit, a waste incinerator, a waste heat boiler, a power generation unit, an exhaust gas purification unit, a smoke exhaust system, a fly ash collection unit, and a slag collection system.

[0037] The waste fly ash gasification melting harmless disposal subsystem includes: a fly ash bin, a carbon-based raw material bin, a binder bin, a garbage fly ash molding unit, a hot melting gasifier and a glassy slag collection unit. Among them, the fly ash bin i...

Embodiment 2

[0053] On the basis of Example 1, the thermal melting gasifier can be a lump coal slag gasifier.

[0054] When the lump coal slag gasifier is used, the molded fly ash fuel is sent into the furnace from the top of the lump coal slag gasifier, and a 3-6 meter gasification bed material layer is established, and the gasification agent is introduced at the same time. Through a number of gasification agent inlets distributed around the furnace body of the lump coal slag gasification furnace, it enters the furnace, and the gasification agent and fly ash fuel undergo redox reactions.

[0055] The gasification agent is divided into pure oxygen / air and water vapor / carbon dioxide, which are respectively fed into the hot melting gasifier through two pipelines.

[0056] The lump coal slag gasifier is mainly composed of a gasification chamber, a slag chamber, a combustion short and a slag quenching chamber. Redox reactions occur in the gasification chamber, and the reaction temperature in t...

Embodiment 3

[0058] On the basis of Example 1, the hot melting gasifier can be a plasma hot melting furnace.

[0059] When a plasma melting furnace is used, the molded fly ash fuel is fed into the furnace from the top of the plasma melting furnace, and a 2-4 meter gasification bed material layer is established. Oxidation-reduction reaction with fly ash fuel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com