Tetragonal phase A and B site co-substituted lead-free piezoelectric textured ceramic with excellent temperature stability as well as preparation method and application of tetragonal phase A and B site co-substituted lead-free piezoelectric textured ceramic

A lead-free piezoelectric and tetragonal phase technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can Solve problems such as the deterioration of the temperature stability of the piezoelectric coefficient, and achieve the effects of widening the temperature range, excellent temperature stability, and high piezoelectric coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Specific embodiment 1: In this embodiment, the tetragonal phase A and B sites with excellent temperature stability are co-substituted for lead-free piezoelectric textured ceramics, and its general chemical formula is (Ba 1-x Ca x )(Ti 1-y E. y )O 3 , where E is Zr or Hf, 0.12<x<0.30, 0<y<0.09;

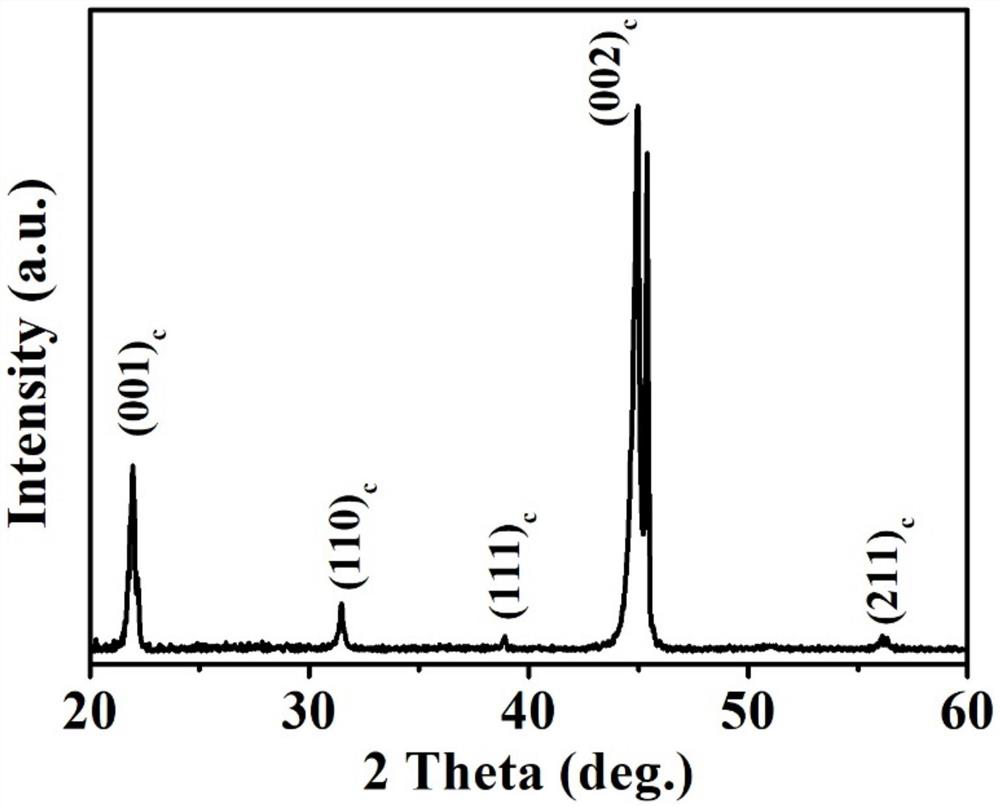

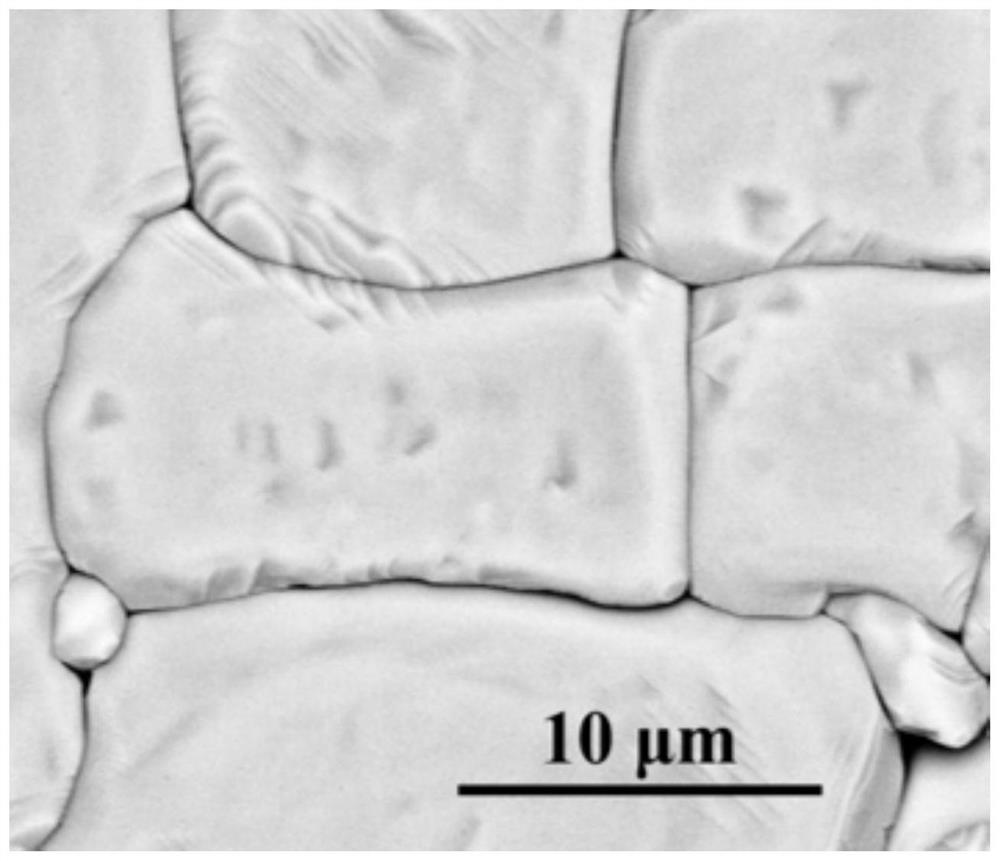

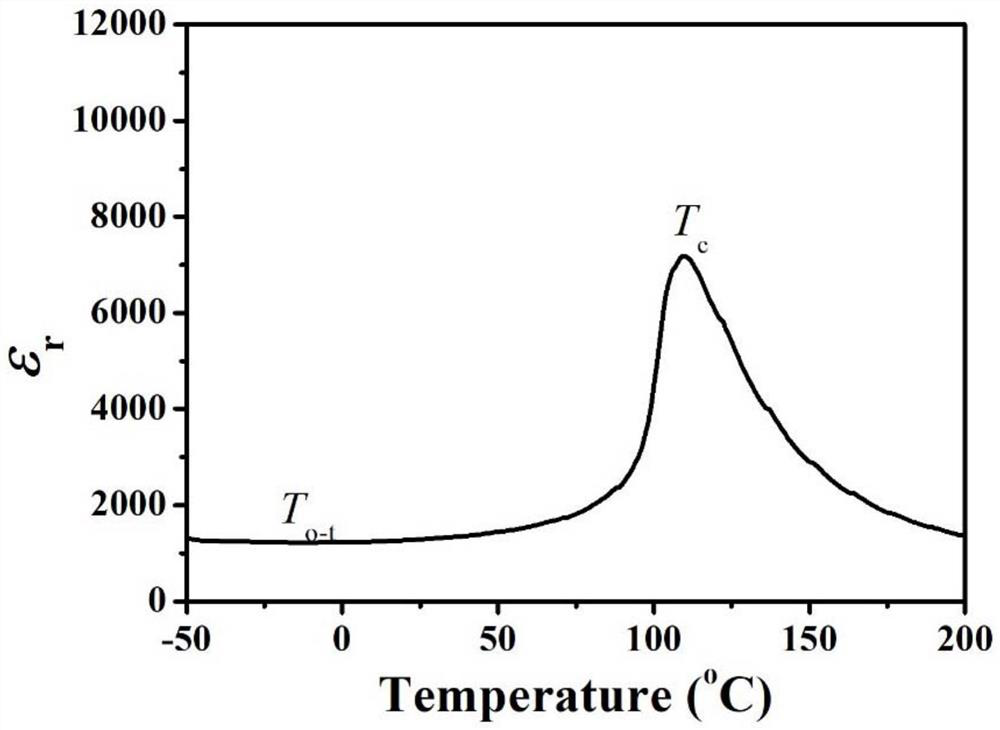

[0034] The orthorhombic O-tetragonal T phase transition temperature T o-t Below room temperature, the ceramic is a perovskite structure of pure tetragonal phase (T) at room temperature, by [001] c or[111] c Tetragonal phase grains with preferred orientation, the preferred orientation degree is above 90%; when the tetragonal phase grains along the [001] c When the orientation is preferred, the cross-section of the ceramic is a cuboid brick wall; when the tetragonal grains are along the [111] c When the preferred orientation is selected, the ceramic cross-section is a diamond-like stacking morphology;

[0035] The Curie temperature of the tetragonal phase A and B co-substi...

specific Embodiment approach 2

[0037] Embodiment 2: This embodiment differs from Embodiment 1 in that the rate of change of the piezoelectric coefficient in the range from room temperature to Curie temperature is less than 10%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0038] Specific Embodiment Three: In this embodiment, the tetragonal phase A and B sites with excellent temperature stability co-substitute the preparation method of lead-free piezoelectric textured ceramics, which is completed according to the following steps:

[0039] 1. Preparation of precursor base material:

[0040] The general chemical formula of the target component of textured ceramics (Ba 1-x Ca x )(Ti 1-y E. y )O 3 The stoichiometric ratio is based on weighing BaCO 3 Powder, CaCO 3 Powder, TiO 2 Powder and ZrO 2 Powder as raw material, or weigh BaCO 3 Powder, CaCO 3 Powder, TiO 2 Powder and HfO 2 Powder is the raw material; the weighed raw material is made of ethanol as the ball milling medium, and after ball milling, drying, pre-calcination, secondary ball milling, drying and sieving, the precursor base material is obtained; where E is Zr or Hf, 0.12 <x<0.30, 0<y<0.09;

[0041] The TiO 2 Powder, ZrO 2 Powder and HfO 2 The particle size of the powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com