Environment-friendly water-based asphalt waterproof coating and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

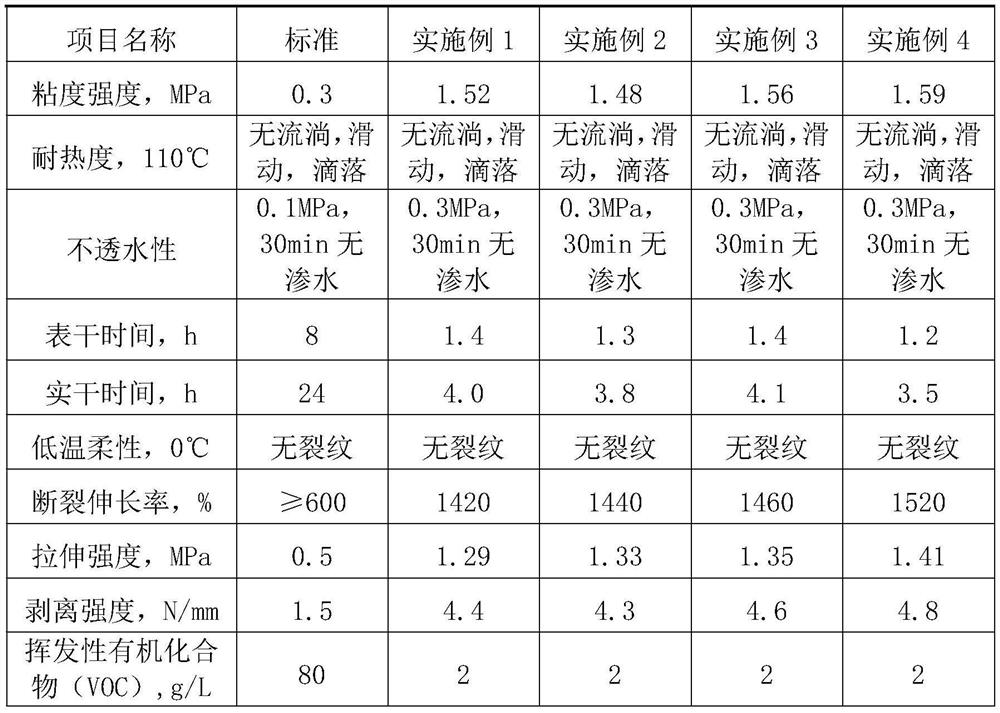

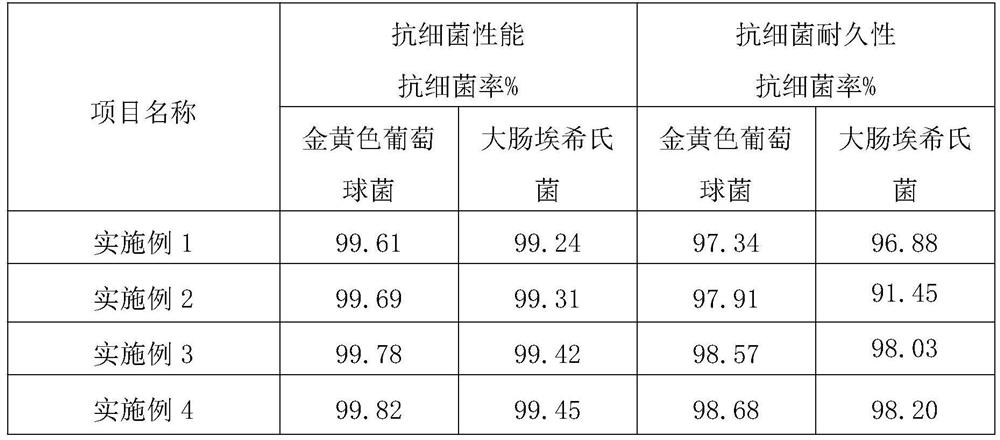

Examples

Embodiment 1

[0035] The preparation method of an environment-friendly water-based asphalt waterproof coating is as follows: add 10 parts of water and 25 parts of acrylic acid emulsion into a container and stir evenly at a low speed, then add 3 parts of defoamer and mix evenly at a speed of 700rpm, and then add 20 parts of inorganic fillers and 1 part of dispersant, stirred at a rate of 1000rpm for 30min; at a rate of 650rpm, sequentially added 60 parts of emulsified silane-modified asphalt, 20 parts of chloroprene latex, and stirred for 10 minutes; finally added 1 part of thickener and 0.5 parts of compound fungicide and 2 parts of solubilizer, and continue to stir for 5 minutes.

[0036] The preparation method of the above-mentioned emulsified silane-modified asphalt is as follows: add 8 parts of anionic slow-cracking emulsifier JY-AFF1 to 24.5 parts of water and dissolve at 50 ° C, add 15 wt% sodium hydroxide lye to adjust the pH value between 12-13, Then add 1.5 parts of ethylene glycol...

Embodiment 2

[0045] The preparation method of an environment-friendly water-based asphalt waterproof coating is as follows: add 20 parts of water and 10 parts of acrylic emulsion into a container and stir evenly at a low speed, then add 2 parts of defoamer and mix evenly at a speed of 500 rpm, and then add 30 parts of inorganic fillers and 3 parts of dispersant, stirred at 1200rpm for 20min; at 800rpm, sequentially added 80 parts of emulsified silane-modified asphalt, 15 parts of chloroprene latex, and stirred for 5min; finally added 2 parts of thickener and 0.8 parts of compound fungicide and 4 parts of solubilizer, and continue to stir for 10 minutes.

[0046] The preparation method of the above-mentioned emulsified silane-modified asphalt is: add 3 parts of anionic slow-cracking emulsifier JY-AFF1 to 49 parts of water and dissolve at 40°C, add 10wt% sodium hydroxide lye to adjust the pH value between 12-13, Then add 1 part of sodium carboxymethyl cellulose, mix well and add to the react...

Embodiment 3

[0055] The preparation method of an environment-friendly water-based asphalt waterproof coating is as follows: add 20 parts of water and 20 parts of acrylic acid emulsion into a container and stir evenly at a low speed, then add 1 part of defoamer and mix evenly at a speed of 600 rpm, and then add 10 parts of inorganic fillers and 2 parts of dispersant, stirred at 1100rpm for 30min; at 700rpm, sequentially added 70 parts of emulsified silane-modified asphalt, 5 parts of chloroprene latex, and stirred for 10min; finally added 2 parts of thickener and 1 part of compound fungicide and 3 parts of solubilizer, and continue to stir for 10 minutes.

[0056] The preparation method of the above-mentioned emulsified silane-modified asphalt is as follows: add 5 parts of anionic slow-cracking emulsifier JY-AFF1 to 41.5 parts of water and dissolve at 50 ° C, add 15 wt% sodium hydroxide lye to adjust the pH value between 12-13, Then add 2 parts of polyacrylamide, mix well and add to the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com