Resin composition, master batch containing same, and application

A technology of resin composition and masterbatch, applied in adhesive additives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of high light transmittance and good corrosion resistance of EVA film and other problems, to achieve the effect of low yellowing rate, good yellowing resistance, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

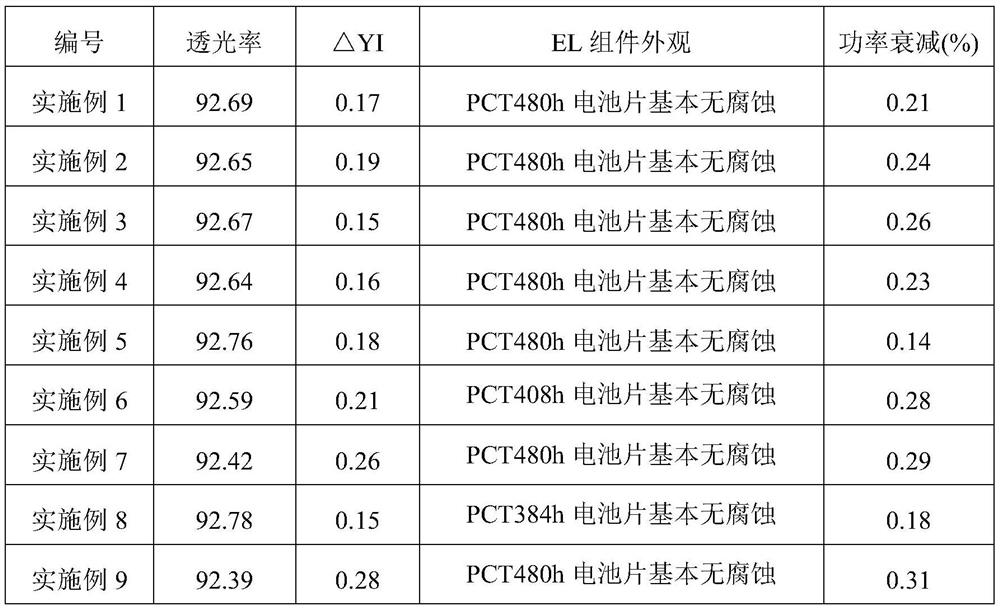

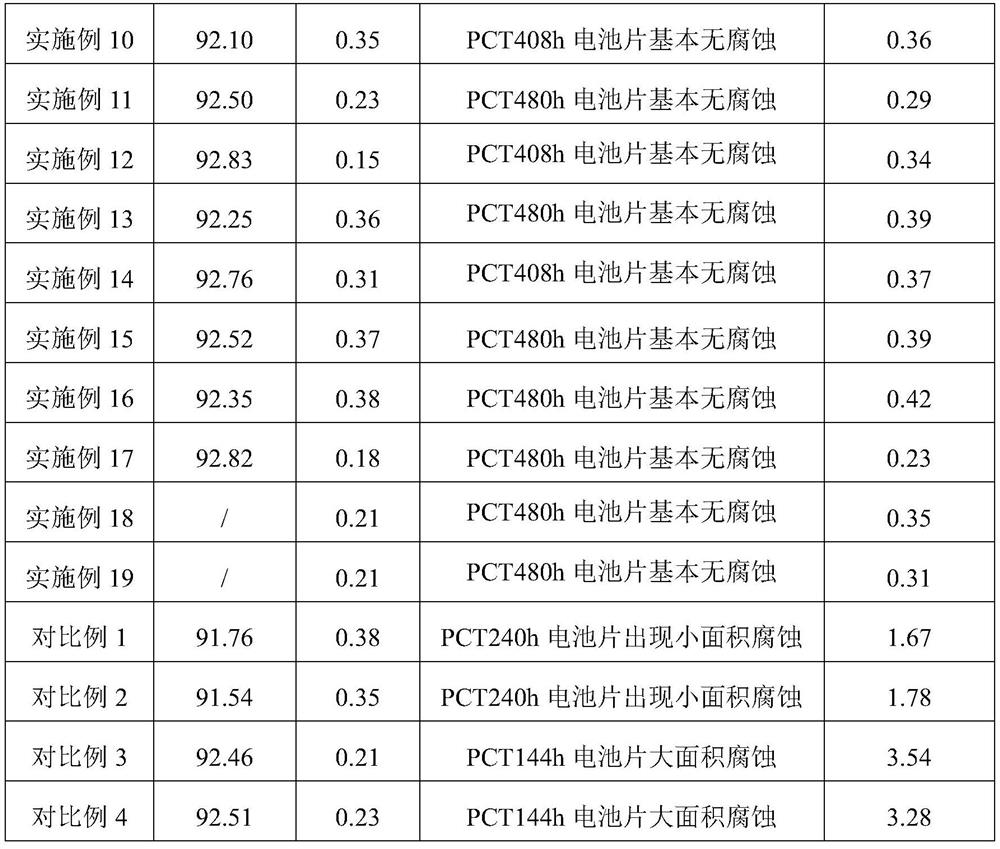

Examples

Embodiment 1

[0046] Form the raw material of resin composition: 100 parts by weight of base resin ethylene-vinyl acetate resin (DuPont), 0.05 parts by weight of organic base compound (7-methyl-1,5,7-triazabicyclo[4.4.0]decane -5-ene, pKa is 14.27), 0.2 parts by weight of crosslinking agent (tert-butyl peroxyisopropyl carbonate), 0.3 parts by weight of auxiliary crosslinking agent (trimethylolpropane trimethacrylate).

[0047] The preparation method is as follows: the above-mentioned raw materials are uniformly mixed, and a single-layer encapsulation adhesive film is obtained through the processes of pre-mixing, melt extruding, film casting, cooling, cutting and winding.

Embodiment 2

[0049] The difference from Example 1 is that the organic base compound is 2-vinyl-4,6-diamino-triazine (pKa is 14.2).

Embodiment 3

[0051] The difference from Example 1 is that the organic base compound is 1,5,7-triazabicyclo[4.4.0]dec-5-ene (pKa is 14.47).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com