Preparation method of vitamin B12 microcapsule tablet

A B12 and vitamin technology, applied in microcapsule preparation, microsphere preparation, function of food ingredients, etc., can solve the problems of insufficient stability of microencapsulated products and single processing of microcapsule solution, and achieve large-scale production and stable solution. , The effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

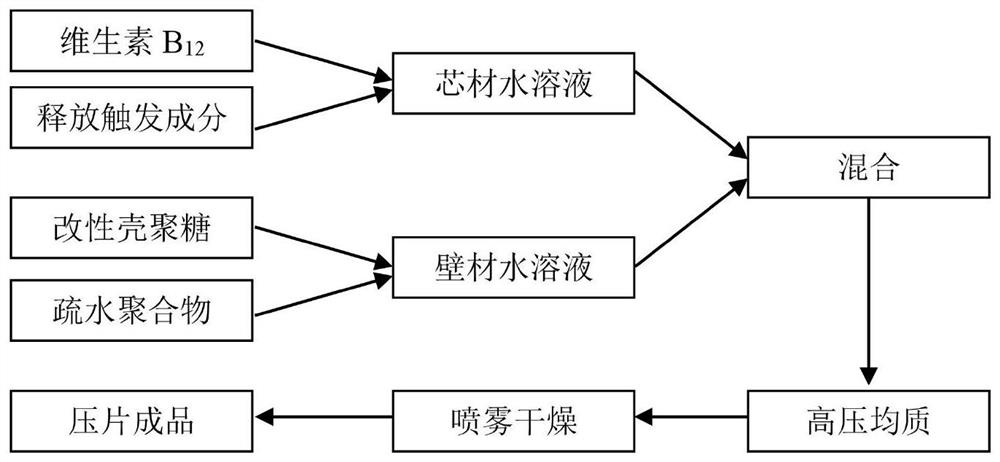

[0026] a B vitamin 12 The preparation method of microcapsule tablet, this method comprises the following steps:

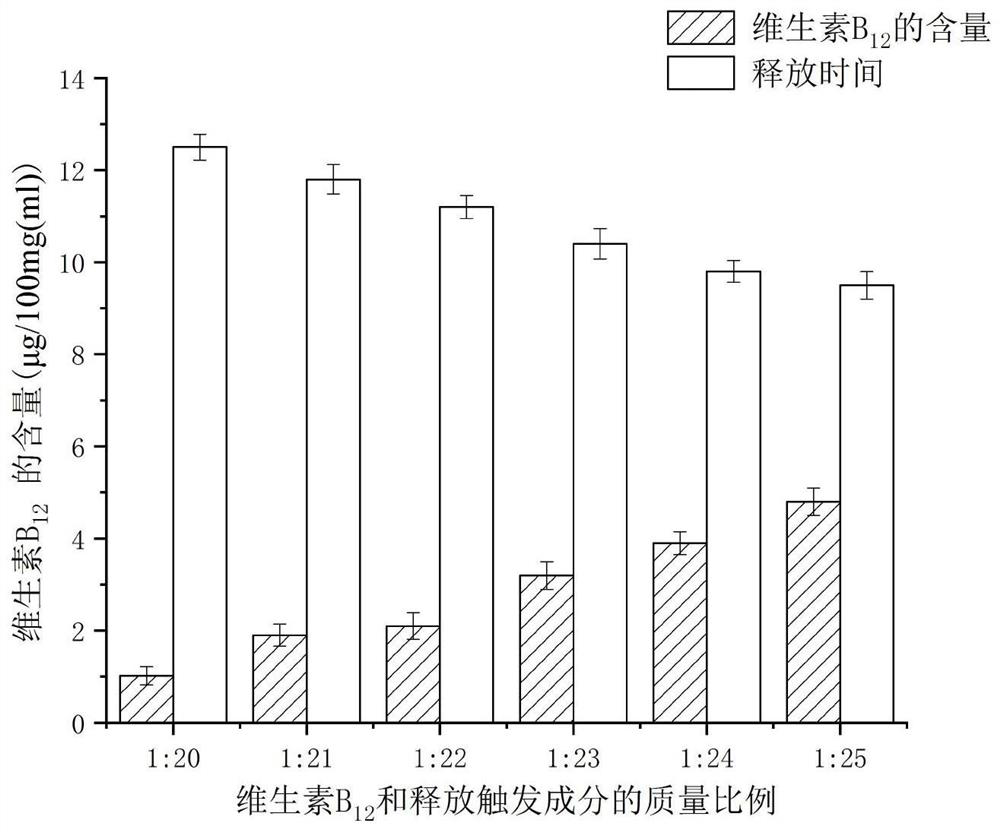

[0027] (1) Weigh 1g of pure vitamin B 12 Solid particles, added to the release trigger component (1:1 chitosan: aminoalkyl methacrylate copolymer), VB 12 The mass ratio (w / w) to the release trigger component is 1:20 to 1:25. After mixing, add it to deionized water, stir on a shaker for 10 minutes and mix well, so as to obtain VB 12 aqueous solution;

[0028] (2) Mix cellulose ether with zein, shellac, gluten, polylactic acid, and hydrophobic starch derivatives in equal proportions to prepare a hydrophobic polymer, and then mix with modified chitosan at a ratio of 1:8 to 1:10 Mix and dissolve in deionized water, and mix well to obtain a wall material aqueous solution;

[0029] (3) Vitamin B 12 The aqueous solution and the wall material aqueous solution are mixed at a ratio of 1:5 to 1:9, and then subjected to high-pressure homogenization treatment. The paramete...

Embodiment 1

[0032] Embodiment 1: A kind of vitamin B 12 The preparation method of microcapsule tablet is characterized in that, comprises the following steps: (1) take by weighing the pure product vitamin B of 1g 12 Solid particles, added to the release trigger component (1:1 chitosan: aminoalkyl methacrylate copolymer), VB 12 The mass ratio (w / w) to the release trigger component is 1:20, after mixing, add it to deionized water, stir on the shaker for 10min and mix well, so as to obtain VB 12 (2) Mix cellulose ether with zein, shellac, gluten, polylactic acid, and hydrophobic starch derivatives in equal proportions to prepare a hydrophobic polymer, and then mix it with modified chitosan at a ratio of 1:8 to dissolve In deionized water, mix uniformly to obtain wall material aqueous solution; (3) vitamin B 12 The aqueous solution and the wall material aqueous solution are mixed at a ratio of 1:5, and then subjected to high-pressure homogenization treatment. Carry out spray drying treatme...

Embodiment 2

[0033] Embodiment 2: A kind of vitamin B 12 The preparation method of microcapsule tablet is characterized in that, comprises the following steps: (1) take by weighing the pure product vitamin B of 1g 12 Solid particles, added to the release trigger component (1:1 chitosan: aminoalkyl methacrylate copolymer), VB 12 The mass ratio (w / w) to the release trigger component is 1:21. After mixing, add it to deionized water, stir on a shaker for 10 minutes and mix well, so as to obtain VB 12 (2) Mix cellulose ether with zein, shellac, gluten, polylactic acid, and hydrophobic starch derivatives in equal proportions to prepare a hydrophobic polymer, and then mix it with modified chitosan at a ratio of 1:8.5 to dissolve In deionized water, mix uniformly to obtain wall material aqueous solution; (3) vitamin B 12 The aqueous solution and the wall material aqueous solution are mixed at a ratio of 1:6, and then subjected to high-pressure homogenization treatment. Carry out spray drying tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com