Pure water-resistant chromatographic stationary phase as well as preparation method and application thereof

A chromatographic stationary phase and a stationary phase technology, applied in the field of pure water-resistant reversed-phase chromatography stationary phase and its preparation, can solve problems such as hydrophobic collapse, and achieve the effects of improved state, simple and feasible steps, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

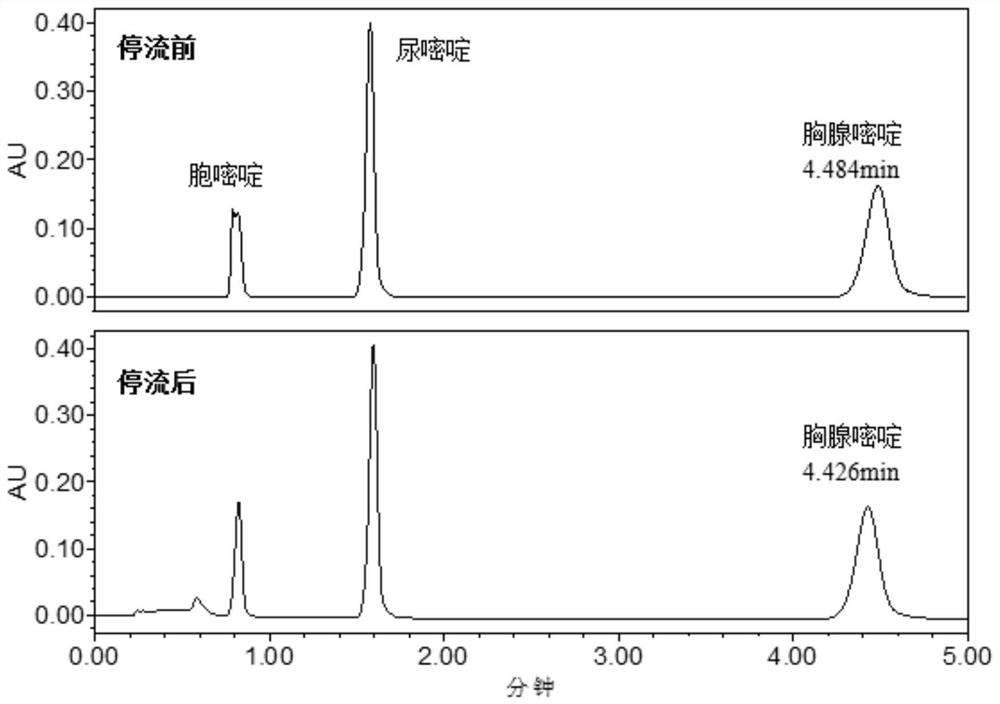

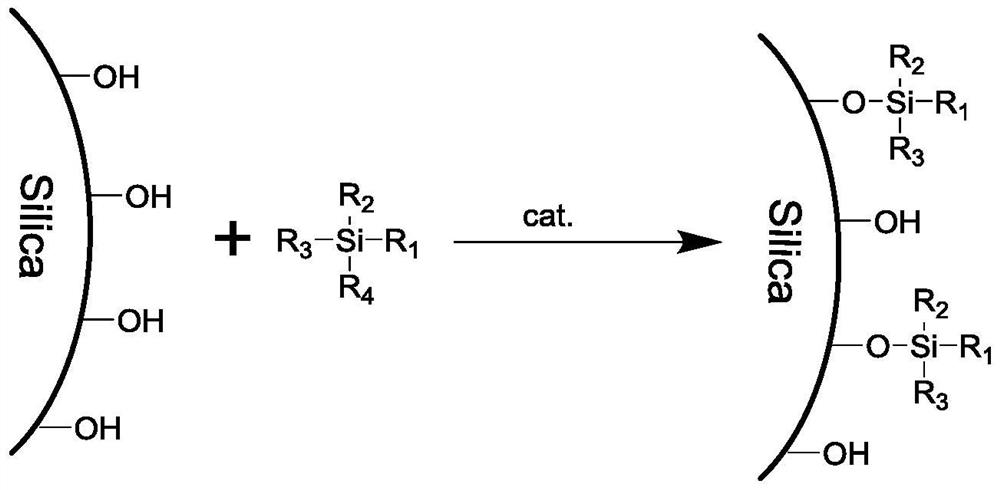

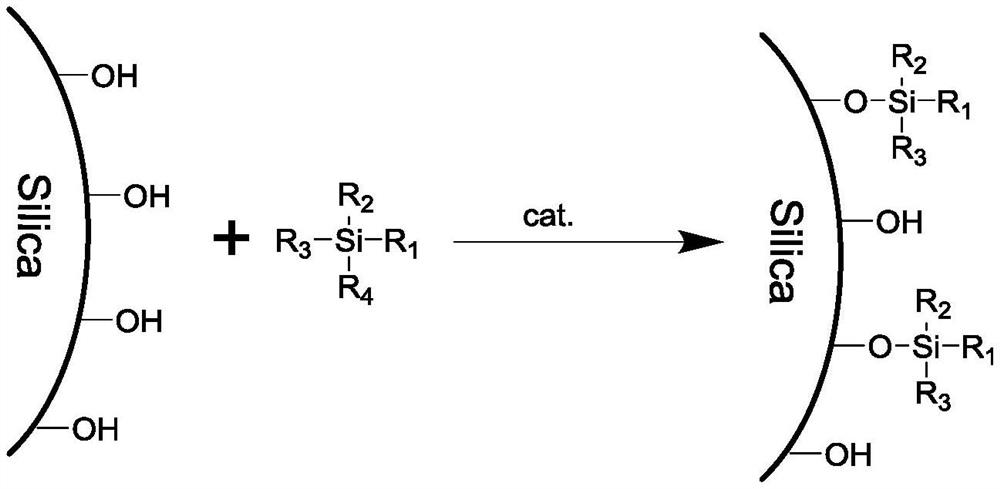

Embodiment 1

[0020] In the three-necked reaction flask, add toluene 100mL, silica gel 20g (average particle size is 2.5μm, average pore diameter is 10nm, specific surface area is 300m 2 / g), pyridine 4g, stirring to fully disperse and infiltrate the silica gel, add 6g of octadecyldimethylchlorosilane, react at 110°C, react for 12hr, and cool down; Wash with 50% methanol / water (v / v) and methanol; take out the solid and dry it in vacuum at 80°C for 12 hours to obtain 24g of the product. The carbon mass content of the product element analysis is 11%, and the calculated stationary phase bonding density is 1.77μmol / m 2 . The product is filled with a 4.6*50mm (diameter and height) column for detection. The detection method is: use 10mM ammonium formate aqueous solution as the mobile phase (without organic solvent), flow rate 1mL / min, and the sample is a mixture of cytosine, uracil and thymine , record the retention time t of thymine after injection 1 ; After the analysis, set the flow rate to...

Embodiment 2

[0022] According to Example 1, the difference is that the silica gel particle size used is 5 μm, the pore diameter is 10 nm, and the specific surface area is 300 m 2 / g; the silane is octyldimethylchlorosilane, and the silane dosage is 5g. Finally, 23g of the product is obtained, the carbon content of the product is 5.5%, and the calculated bonding density is 1.86 μmol / m 2 , and the percent change in thymine retention time was 1.5%.

Embodiment 3

[0024] According to Example 1, the difference is that the silica gel particle size used is 10 μm, the pore diameter is 10 nm, and the specific surface area is 300 m 2 / g; the silane is hexadecyltrimethoxysilane, the silane feed rate is 18g, the product is 24g, the product carbon content is 11%, and the calculated bonding density is 2.0μmol / m 2 , and the percent change in thymine retention time was 0.82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com