Catalyst for isodewaxing hydrocracking tail oil and preparation method thereof

A technology of hydrocracking tail oil and isomerization dewaxing, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., and can solve the problem of incompatibility between metal active sites and carrier acid centers, and the difficulty of industrialization of the process , complex preparation process and other issues, to achieve good addition/dehydrogenation activity and isomerization performance, excellent selectivity, and reduce agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

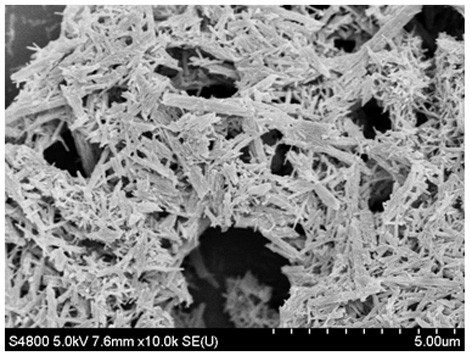

[0031] Weigh the ZSM-22 molecular sieve 65 g, ZSM-5 molecular sieve 10 g to add the ball mill, then put the mill of 100 g of 5 mm, 250 RPM ball milling for 10 min; then add 0.744 g of Pt (NH) 3 ) 4 (NO 3 ) 2 The ball mill is continued in 250 rpm for 10 min. It is weighed with a thin water aluminum stone 11g, Tianjing powder 2g, and mix it with the ball milling composite powder, then add 75 g of nitric acid solution (add water by 1.5 g of concentrated nitric acid to add water), after 13 minutes, select aperture 2.7 mm four-leaf-type orifice plate extrusion is formed; after 20 minutes of booth, cut into 2 mm small segments, then put it in 120 ° C for 12 h, after removal, take out to vent the air under air conditions for 4 h, result Heterogeneous dewaxed catalyst S1.

Embodiment 2

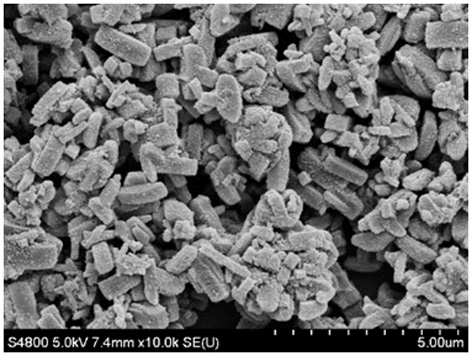

[0033]ZSM-23 zeolite weighed 65g, H-β zeolite was added 10g ball mill jar, and then placed 100 g of balls of 5mm diameter, 250 rpm milling 10min; was then added 0.744g Pt (NH 3 ) 4 (NO 3 ) 2 To 250rpm continue milling 10min. After weighing 11g quasi boehmite, sesbania powder 2g, which was well mixed composite powder with a ball mill, and then added a solution of 75 g of nitric acid (concentrated nitric acid was added 1.5 g of water dubbed), kneaded for 13 minutes selection aperture Clover orifice 2.7 mm extrusion molding; share cool after 20 minutes, cut into small pieces 2 mm, and then placed in an oven at 120 deg.] C bake 12 h, after removing baked at 350 deg.] C into 4h under atmospheric conditions, to give iSODEWAXING catalyst S2.

Embodiment 3

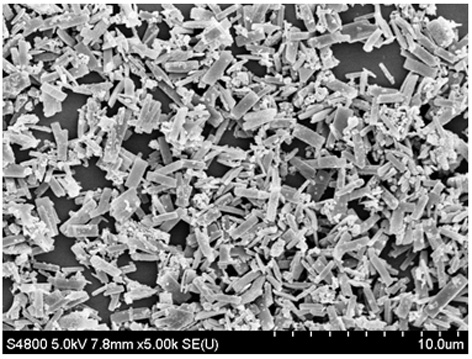

[0035] Zeolite ZSM-22 weighed 65 g, H-β zeolite was added 10 g in a ball mill pot, and then placed 100 g of balls of 5mm diameter, 250 rpm milling 10 min; then added 0.744g Pt (NH 3 ) 4 (NO 3 ) 2 To 250 rpm to continue milling 10min. After weighing 11g quasi boehmite, sesbania powder 2g, which was well mixed composite powder with a ball mill, and then added a solution of 75 g of nitric acid (concentrated nitric acid was added 1.5 g of water dubbed), kneaded for 13 minutes selection aperture Clover orifice 2.7 mm extrusion molding; share cool after 20 minutes, cut into small pieces 2 mm, and then placed in an oven at 120 deg.] C bake 12 h, after removing baked at 350 deg.] C into 4h under atmospheric conditions, to give isomerization dewaxing catalyst S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com