Photo-anode material and preparation method thereof

A photoanode and composite material technology, applied in the field of electrochemical applications, can solve the problem that the photoelectric response performance of photoanode materials needs to be further improved, and achieve the effect of excellent photoelectric response performance and photoelectric response improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

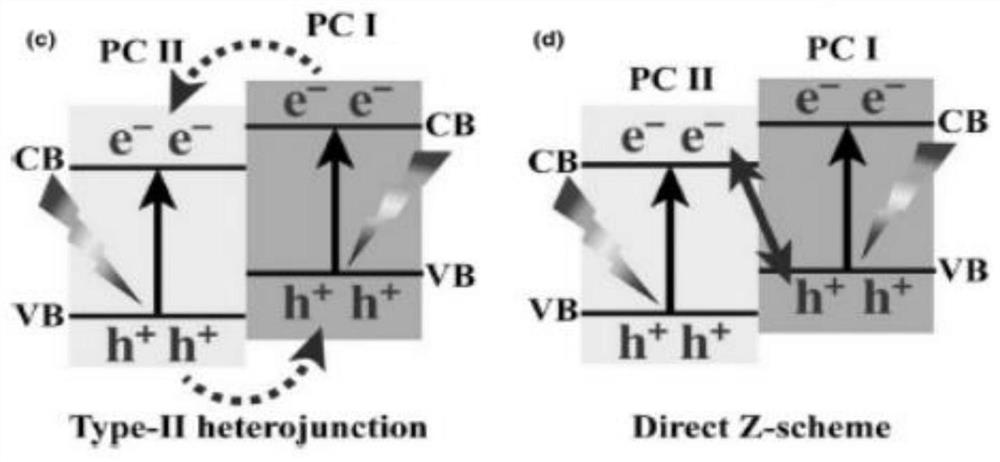

AI Technical Summary

Problems solved by technology

Method used

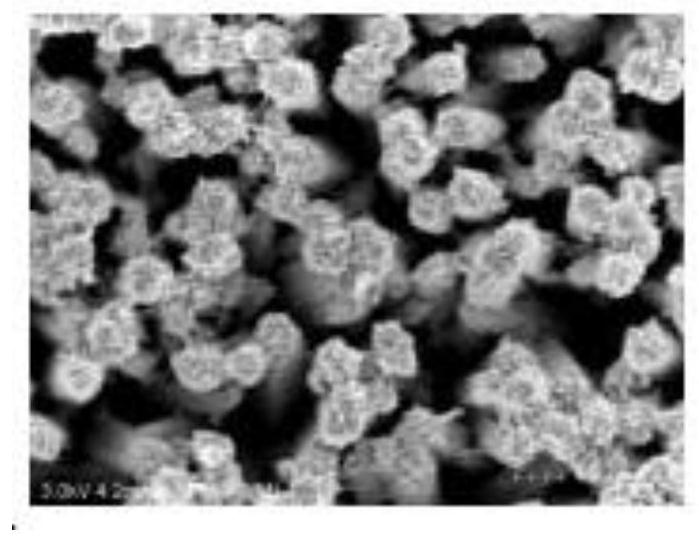

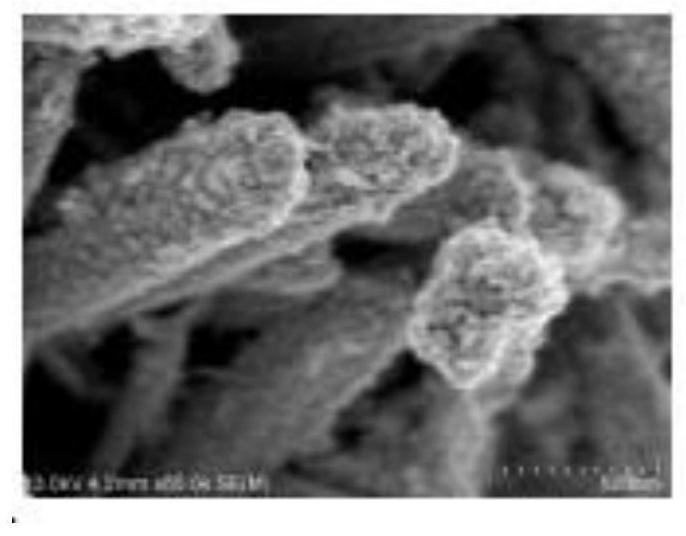

Image

Examples

preparation example Construction

[0022] The application provides a method for preparing a photoanode material, comprising the following steps:

[0023] S1. React the molybdenum source and the selenium source in water under the action of a reducing agent to obtain a molybdenum diselenide precursor solution; put the titanium dioxide into a tubular furnace with an ammonia atmosphere for gradient temperature annealing to produce titanium nitride ;

[0024] S2. Put the titanium nitride into the polytetrafluoroethylene lining, add the molybdenum diselenide precursor solution, and react hydrothermally at a temperature of 170-180°C to obtain MoSe 2 @TiN composites;

[0025] S3, the MoSe 2 The @TiN composite material is annealed at 400-500°C under an inert atmosphere to obtain MoSe 2 @TiN photoanode material.

[0026] Compared with traditional materials, the photoanode material prepared by the invention has significantly better photoelectric response performance, which is beneficial to the application in photocata...

Embodiment 1

[0038] (1) TiO 2Put it into a tube furnace with an ammonia atmosphere for gradient heating (the first stage: 1min, 10°C to 600°C; the second stage: 1min, 2°C to 800°C, hold for 2h) annealing treatment, the production into TiN.

[0039] (2) MoSe 2 Preparation of the precursor: Take 50mL of deionized water, 0.8g of ammonium molybdate tetrahydrate as the molybdenum source, 0.7g of Se powder as the Se source, and hydrazine hydrate as the reducing agent. Dissolve ammonium molybdate in water and stir for 10 minutes to obtain liquid A, then dissolve Se powder in hydrazine hydrate to obtain liquid B; mix liquid A and liquid B and stir for 30 minutes to obtain MoSe 2 precursor solution.

[0040] (3) Hydrothermal: put the obtained TiN into the polytetrafluoroethylene lining with the conductive side facing down, and add the above MoSe 2 Precursor solution, hydrothermal at 180°C for one hour to obtain MoSe 2 @TiN, take it out, wash it and vacuum dry it, set it aside.

[0041] (4) Th...

Embodiment 2

[0045] (1) TiO 2 Put it into a tube furnace with an ammonia atmosphere for gradient heating (the first stage: 1min, 10°C to 600°C; the second stage: 1min, 2°C to 800°C, hold for 2h) annealing treatment, the production into TiN.

[0046] (2) Mix the selenium powder solution and the sodium molybdate dihydrate solution, and stir for 30 minutes to obtain a precursor solution. Transfer this precursor solution to a polytetrafluoroethylene-lined autoclave. The selenium powder solution was prepared from 0.158g selenium powder and 5mL hydrazine hydrate; the dihydrate sodium molybdate solution was prepared from 0.242g dihydrate ammonium molybdate and 25mL deionized water.

[0047] (3) Hydrothermal: Put the obtained TiN into the above-mentioned high-pressure reaction kettle lined with polytetrafluoroethylene, with the conductive side facing down, and heat it at 180°C for one hour to obtain MoSe 2 @TiN, take it out, wash it and vacuum dry it, set it aside.

[0048] (4) The dried MoSe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com