Two-dimensional layered heterojunction Ge-GeH, photoelectric anode material and preparation method of two-dimensional layered heterojunction Ge-GeH

A two-dimensional layered, photoanode technology, applied in the field of photoelectric detection, can solve the problems of attenuation, structural degradation performance of two-dimensional layered heterojunction materials, and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a two-dimensional layered heterojunction Ge-GeH, comprising the steps of:

[0035] S1. In an inert gas environment, mix the elemental germanium and the elemental calcium at a mass ratio of 1:0.5, put them into a quartz tube, seal the tube in vacuum, and put the sealed quartz tube into a muffle furnace for high-temperature calcination. The following temperature profile was used: (1) heating to 1000°C at a rate of 4°C / min; (2) annealing at 1000°C for 24 hours; (3) slow cooling to 500°C at a rate of 2°C / min; (4) Cool to room temperature at a rate of 3 °C / min, collect CaGe after calcination 2 crystal;

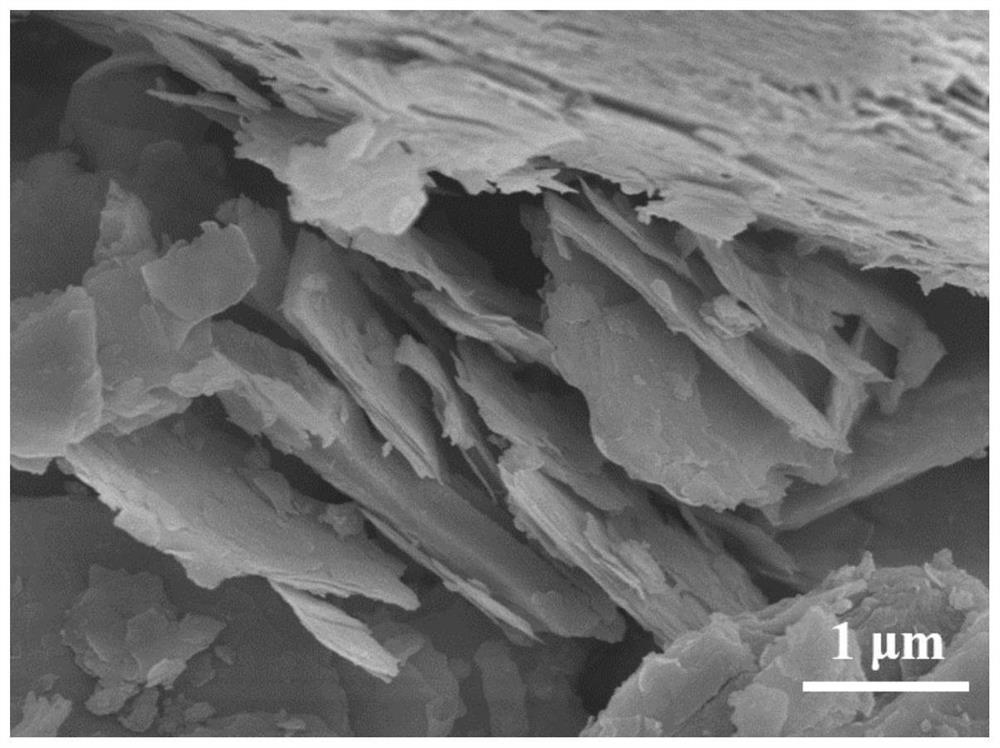

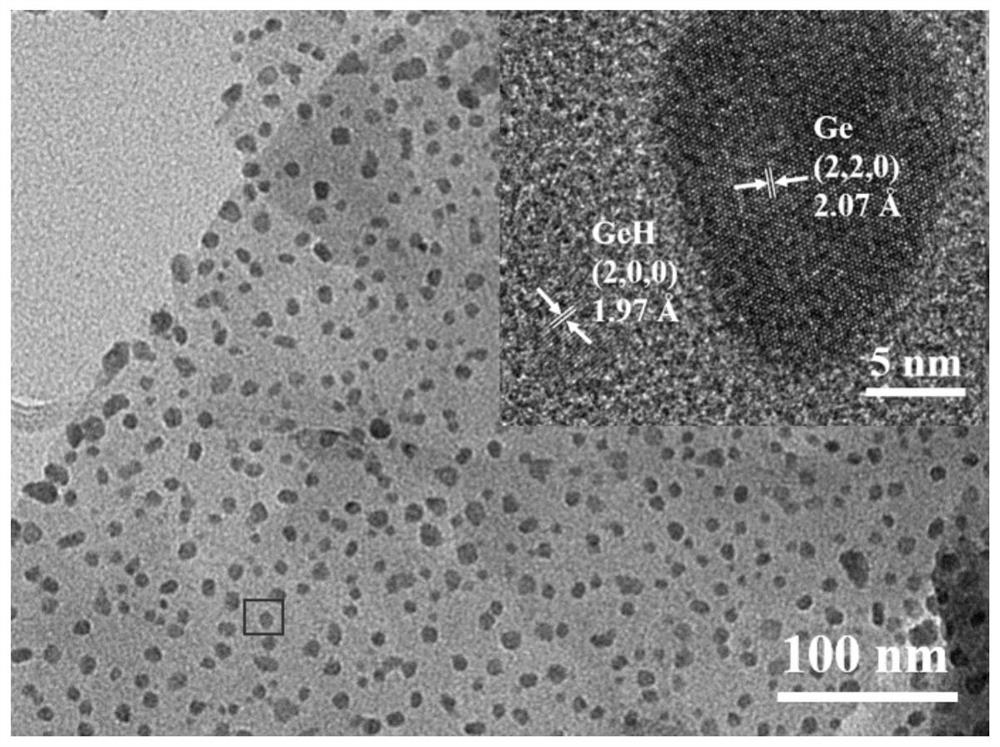

[0036] S2. CaGe to be collected 2 Transfer the crystals to a round bottom flask, add 30mL of concentrated hydrochloric acid, and then use a circulating water vacuum pump to evacuate the round bottom flask to a vacuum state, and stir and react at -30°C for 48h. After washing the suspension, multilayer Ge-GeH is obtained. Add ethanol to the multilayer...

Embodiment 2

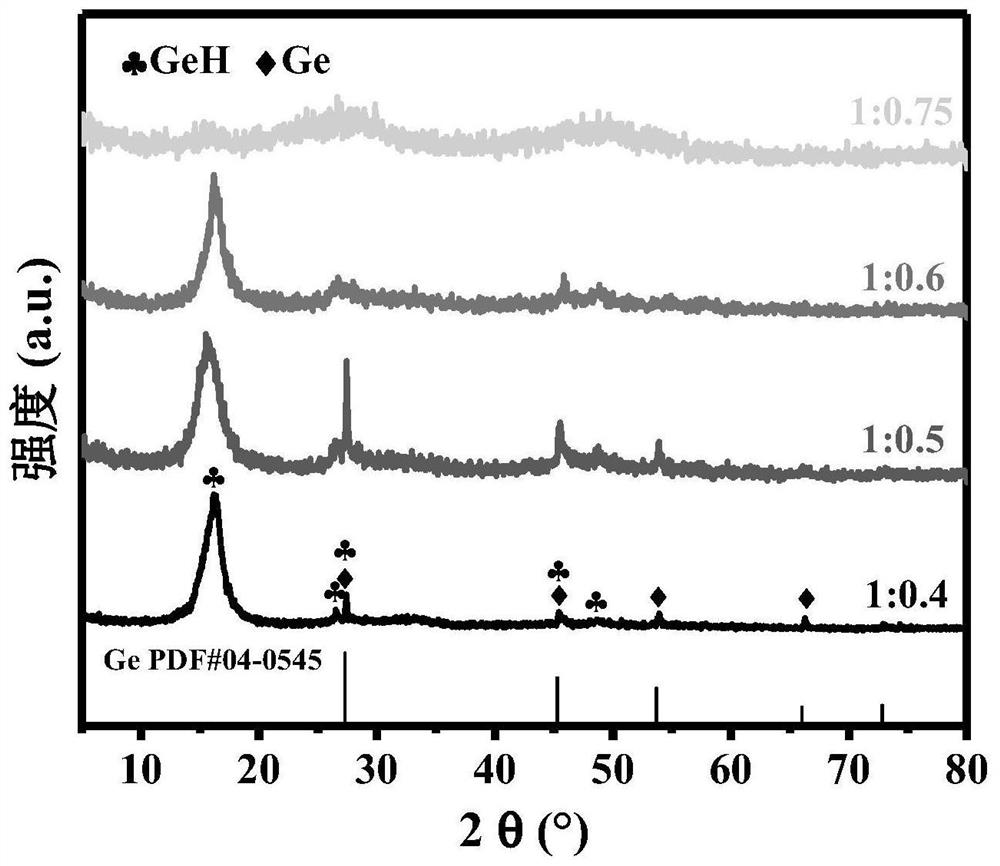

[0039] Different from Example 1, the ratio of germanium to calcium in this example is 1:0.4. The total time consumed for the preparation of the two-dimensional layered heterojunction Ge-GeH described in this example is basically the same as that in Example 1.

Embodiment 3

[0041] Different from Example 1, the ratio of germanium to calcium in this example is 1:0.6. The total time consumed for the preparation of the two-dimensional layered heterojunction Ge-GeH described in this example is basically the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com