A kind of bismuth-based halide perovskite nanosheet and preparation method thereof

A perovskite and nanosheet technology, applied in the field of perovskite nanosheets and its preparation, can solve the problems of poor film flatness, limited application, and many defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

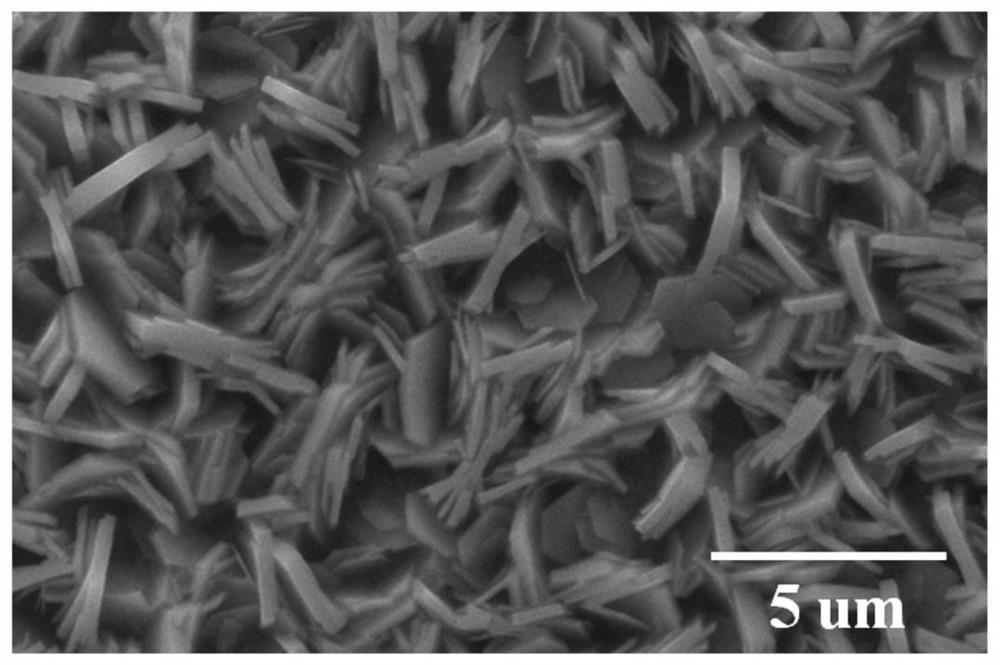

Image

Examples

preparation example Construction

[0027]The method of preparing a two-dimensional perovskite nano film according to the present invention includes the following steps:

[0028]1) Clean the surface cleansing bottom electrode to drop the preparative prepared perovanium ore before the rotary coating film A3BI2I9; Then annealing;

[0029]2) Use a polar solvent treatment while annealing, dissolve-recrystallization; that is, the two-dimensional perovskite nano film is obtained, wherein A = CH3NH3+CS+.

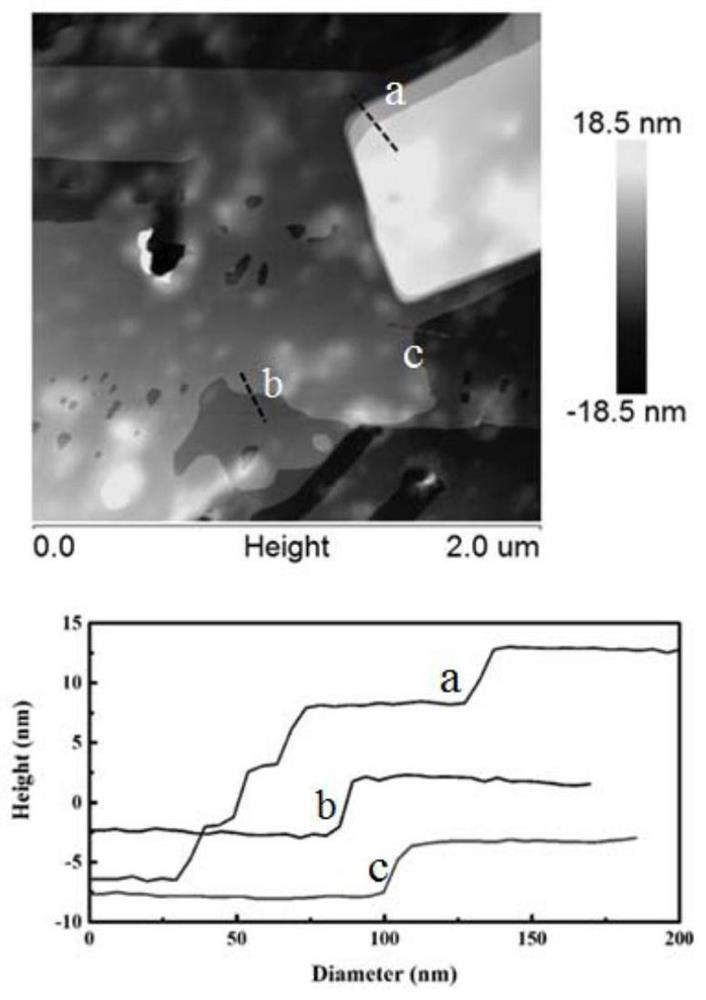

[0030]The single layer thickness of the two-dimensional calcium titanium nano-membrane can minimize 2.0 ± 0.2 nm.

Embodiment 1

[0032]1) Start with washing sperm (about 1 mm) for 20 minutes to remove organic and inorganic stains that may be present on the surface; then rinse with a large amount of tap water; finally put the glass sheet in deionized water Ultrasound Wash 20 minutes; put the above-mentioned glass sheets in anhydrous ethanol for about 20 minutes to remove surface residual organic impurities, and this step repeats more times; then the glass sheet is ultrasonic in acetone for about 20 minutes. Further removal of the surface residual organic impurities; remove the glass sheet substrate from the acetone, placed in an ultraviolet ozone cleaning machine, washed for 30 minutes.

[0033]2) Simultaneously dissolve MAI and BII 3 simultaneously dissolved in the DMF solution at the ratio of 3: 2, stirring at 70 degrees for 12 hours, thereby formulating 1M MA3BI2I9Pre-proliferation of perovskite;

[0034]3) Place the washed glass sheet on the spin coater, adding 200 μm perovskite precursor solution to spin coatin...

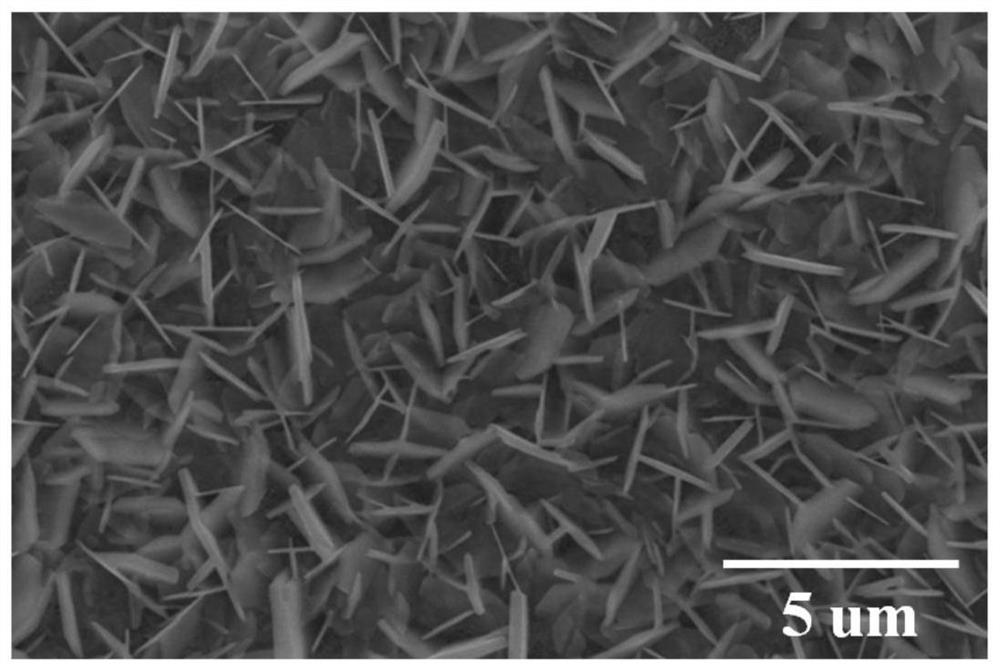

Embodiment 2

[0038]1) Cleaning with detergent, deionized water, anhydrous ethanol, acetone, and ultraviolet ozone cleaning using detergent, deionized water, anhydrous ethanol, acetone.

[0039]2) Simultaneously dissolve CSI and BII 3 simultaneously dissolved in DMF solution at 3: 2, stirred at 70 degrees for 12 hours, thereby configuring 1 M CS3BI2I9Pre-proliferation of perovskite;

[0040]3) Place the washed glass sheet on the spin coater, adding 200 μm perovskite precursor solution to spin coating at 1000 rpm under 1 min after 1000 rpm;

[0041]4) The volume ratio of methanol and DMF is 10: 1 to 50: 1, and the spin-coated glass substrate is placed in the container, and 5 uL ~ 100 ul is added dropwise on the substrate on the substrate. Sex solution, or 50 ul to 200 ul of mixed polar solution, adding the solution vapor to the substrate, so that the perovskite film is immersed in a steam atmosphere of the mixed solution, and after it is dissolved - rejected the crystal, put it Annealing is performed on a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com