High-strength glass fiber composition and preparation method thereof

A glass fiber, high-strength technology, applied in the field of high-strength glass fiber composition and its preparation, can solve the problems of pollution, high magnesium oxide content, affecting human health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

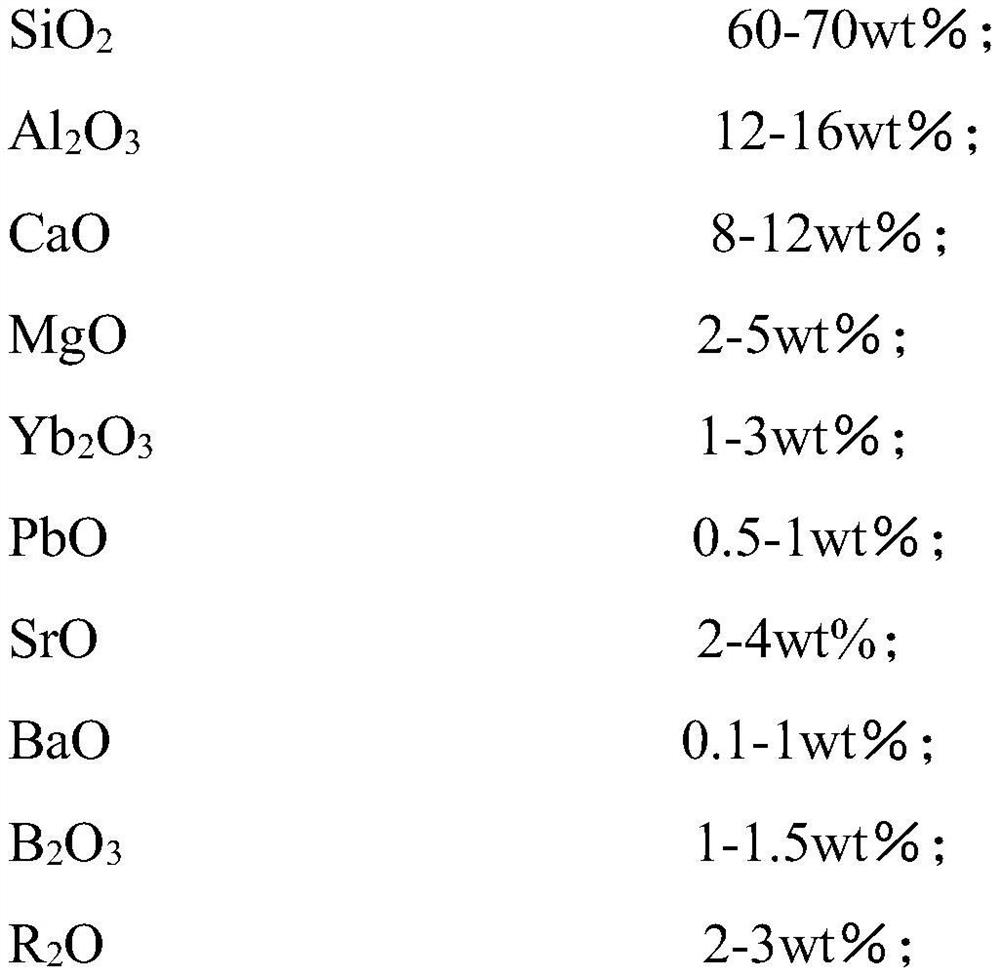

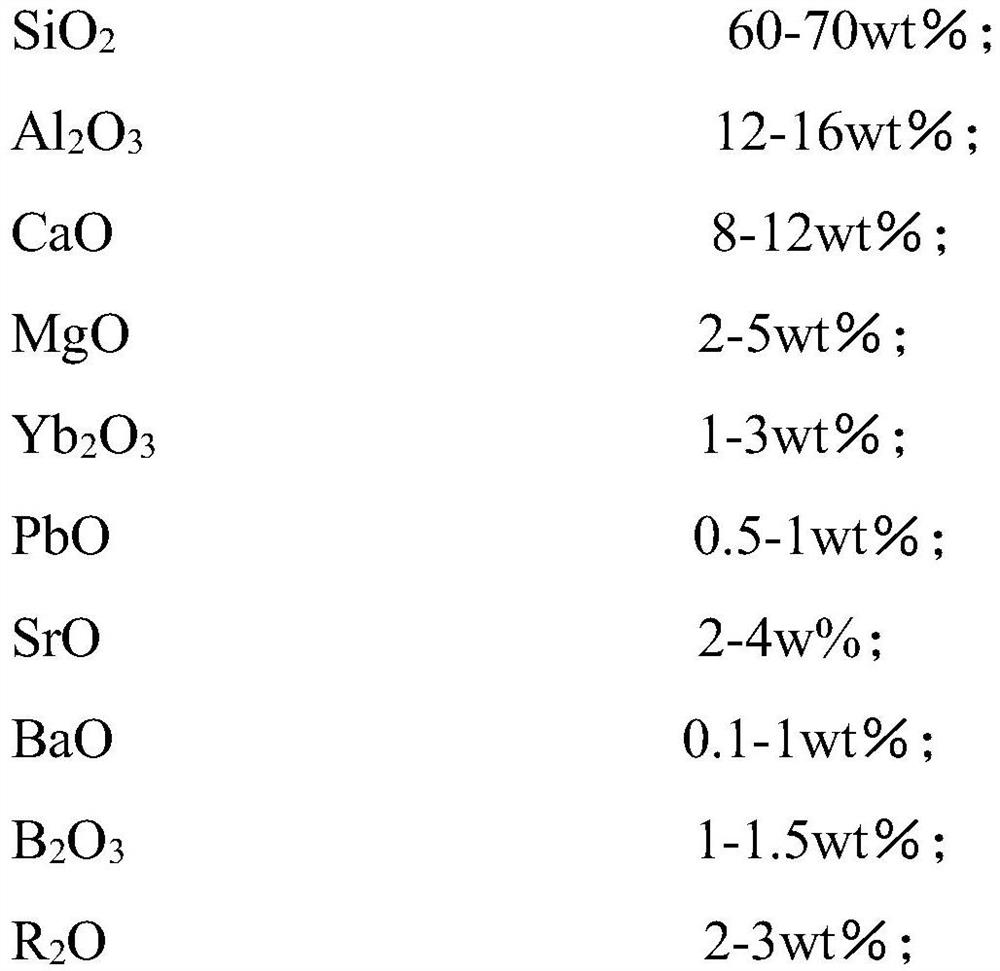

Method used

Image

Examples

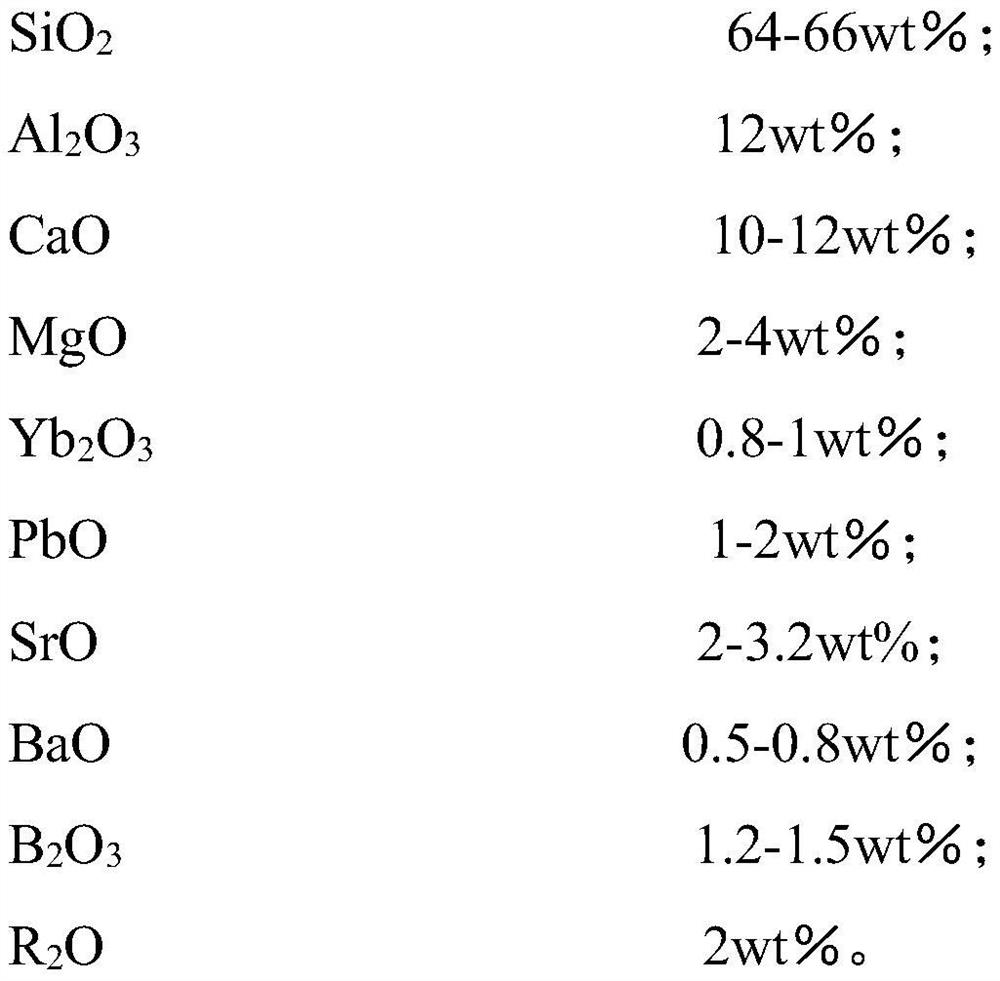

Embodiment 1

[0025] According to the formula of Example 1 in Table 1, the raw materials were weighed, put into a glass melting furnace, vitrified and melted, and then spun and formed to obtain glass fibers. The fiber forming temperature of the high-strength glass fiber composition is 1320-1400°C; the liquidus temperature of the high-strength glass fiber composition is 1270-1310°C. The properties of the prepared glass fibers were tested, and the results are shown in Table 3.

Embodiment 2-7

[0027] According to the formula of Example 2-7 in Table 1, the raw materials were weighed, and the rest of the conditions were the same as in Example 1. The properties of the prepared glass fibers were tested, and the results are shown in Table 3.

[0028] In order to further illustrate the beneficial effects of the present application, due to limited space, only Example 7 is used as an example to construct a comparative example as follows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com