Low-density high-toughness bismaleimide foam material and preparation method thereof

A technology of bismaleimide and foam material is applied in the field of bismaleimide foam material to achieve the effect of realizing foaming ability and avoiding high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

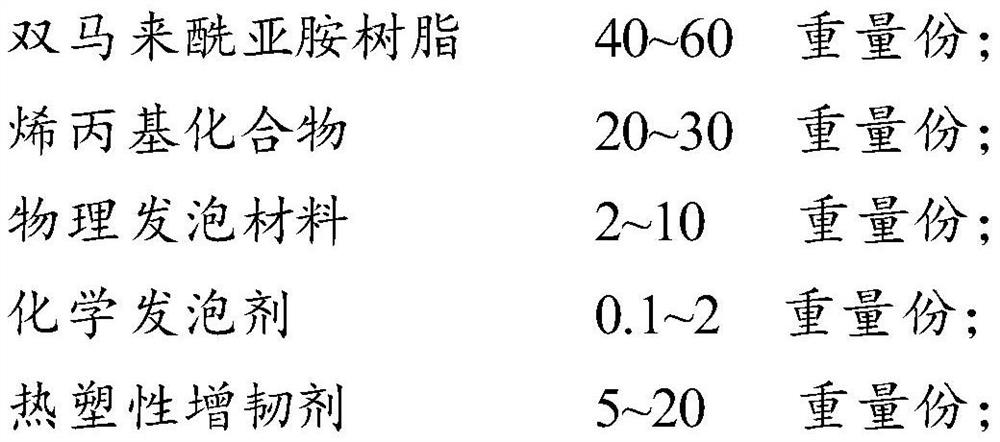

Method used

Image

Examples

preparation example Construction

[0093] The present invention also provides a kind of preparation method of bismaleimide foam material, comprises the following steps:

[0094] (1) After the bismaleimide and the allyl compound are reacted, a prepolymer is obtained;

[0095] (2) After mixing the prepolymer obtained in the above steps, physical foaming material, chemical foaming agent, thermoplastic toughening agent, thixotropic agent, surfactant and inorganic filler, after carrying out foaming and curing in the mould, then After post-curing, a bismaleimide foam material is obtained.

[0096] In the invention, firstly, the prepolymer is obtained by reacting the bismaleimide and the allyl compound.

[0097] In the present invention, the reaction temperature is preferably 130-150°C, more preferably 134-146°C, more preferably 138-142°C.

[0098] In the present invention, the reaction time is preferably 1-3 hours, more preferably 1.4-2.6 hours, more preferably 1.8-2.2 hours.

[0099] The present invention then mi...

Embodiment 1

[0122] According to N, N'-(4,4-methylene diphenyl) bismaleimide resin 40%, allyl bisphenol A 24%, react at 140°C for 2 hours, add to the prepolymer F230D 10%, azodicarbonamide 1%, polyetherimide 10%, fumed silica 2%, AK-8890 3%, expandable graphite 10%, stir evenly, and place in an aluminum mold. Heating at 150°C for 2 hours, foaming and curing during this process, continue to heat to 180°C for 2 hours, then heat to 200°C for 2 hours, and finally heat to 250°C for 2 hours. After taking it out, it was cooled to room temperature to obtain a bismaleimide foam.

Embodiment 2

[0124] According to 50% bis(3-ethyl-5-methyl-4-maleimidophenyl) methane resin, 30% diallylamine, react at 130°C for 2 hours, add to the prepolymer 920DU40 8%, N,N-dinitrosopentamethylenetetramine 1%, polyaryletherketone 10%, fumed silica 2%, B-8002 3%, expandable graphite 10%, stir evenly, set in an aluminum mold. Heating at 140°C for 2 hours, foaming and curing during this process, continue to heat to 160°C for 2 hours, then heat to 180°C for 2 hours, and finally heat to 230°C for 2 hours. After taking it out, it was cooled to room temperature to obtain a bismaleimide foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com