Vaporizing tower for producing gas-mixed carbon black

A gas-mixed carbon black and vaporization tower technology, applied in fibrous fillers and other directions, can solve problems such as inability to run continuously and stably, and achieve the effects of saving gas consumption, ensuring product quality, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

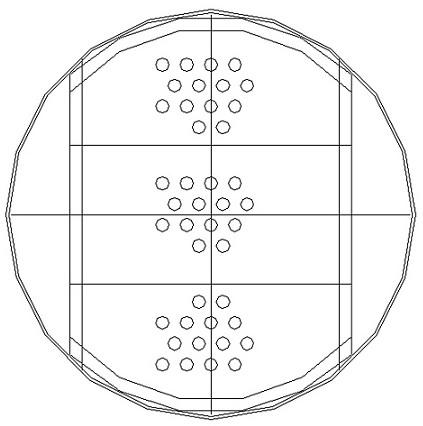

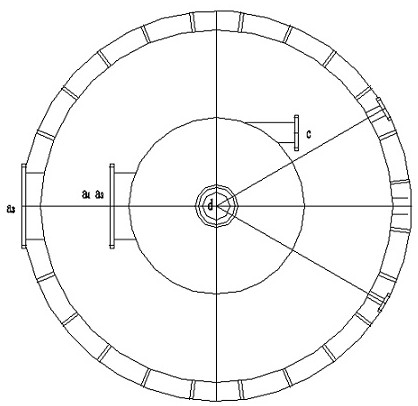

Image

Examples

Embodiment 1

[0028] The raw material oil pump pumps the anthracene oil out of the oil storage tank, preheats the anthracene oil at 250°C through the heat exchanger, and enters the vaporization tower through the evenly distributed small holes under the pipeline of the raw material (anthracene oil) distributor (3), and enters the oil The flow rate is adjusted according to the liquid level at the bottom of the tower. After the coke oven gas passes through the flow meter of the orifice plate, it is preheated to about 360°C by using the waste heat of the production line, and enters evenly from three directions of the vaporization tower through the coke oven gas distributor (2). Due to the different depths of the oil layer in the vaporization tower, the coke oven gas directly passes into the oil layer in the tower, which plays a role in agitating the oil in the tower. The oil in the tower realizes heat exchange in two ways: convection and conduction. The tower bottom oil is pumped out of the towe...

Embodiment 2

[0030] The raw material oil pump pumps the anthracene oil out of the oil storage tank, preheats the anthracene oil at 250°C through the heat exchanger, and enters the vaporization tower through the evenly distributed small holes under the pipeline of the raw material (anthracene oil) distributor (3), and enters the oil The flow rate is adjusted according to the liquid level at the bottom of the tower. After the coke oven gas passes through the flow meter of the orifice plate, it is preheated to 360°C by using the waste heat of the production line, and enters the vaporization evenly from three directions of the vaporization tower through the coke oven gas distributor (2). Due to the different depths of the oil layer in the tower, the coke oven gas directly passes into the oil layer in the tower and plays a role in agitating the oil in the tower. The oil in the tower realizes convection and heat conduction, and the gasification of the oil in the tower is rapid and stable. The oil h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com