Molybdenum sulfide/fluoride host-guest catalytic material, preparation method and application

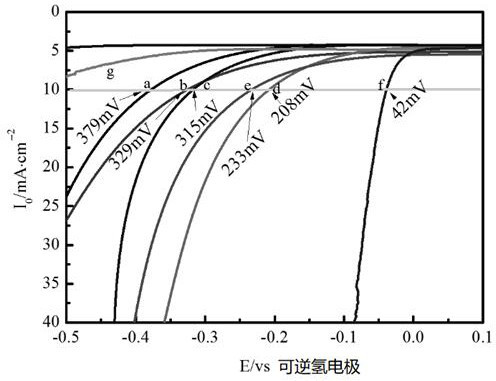

A catalytic material, fluoride-based technology, applied in the direction of electrolysis components, electrodes, electrolysis process, etc., can solve the problems that the size of ion channels cannot be changed, the ability and stability of hydrogen evolution need to be improved, and achieve the improvement of electrocatalytic activity and ability of hydrogen evolution , the effect of widening ion channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

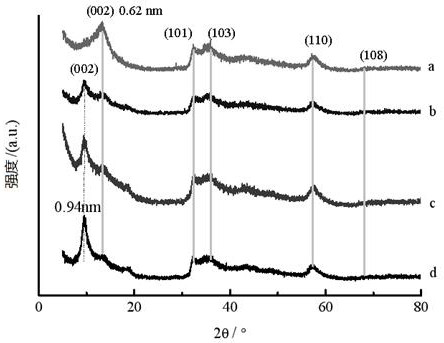

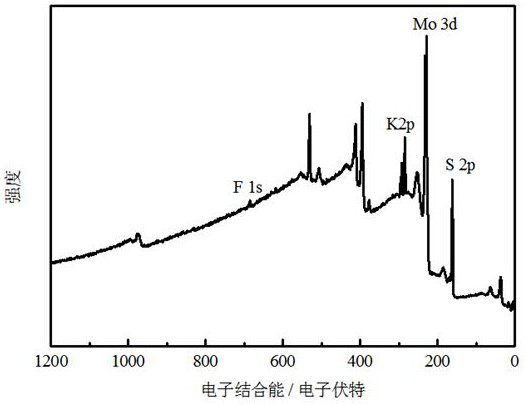

[0029] Weigh 2.42g (0.01mol) sodium molybdate (Na 2 MoO 4 .2H 2 O), dissolved in 30 mL of deionized water, and ultrasonically dispersed for 30 minutes. Another weighed 3.05g (0.04mol) thiourea [(NH 2 ) 2 CS], dissolved in 30mL deionized water, ultrasonically dispersed for 30 minutes. The thiourea aqueous solution was added dropwise into the sodium molybdate aqueous solution, and the mixed solution was ultrasonically dispersed for 30 minutes. After the ultrasonication, the mixed aqueous solution was fixed to 80mL and transferred to a 100mL polytetrafluoroethylene-lined high-pressure hydrothermal reactor, the reactor was sealed, and then placed in a constant temperature box and heated to 200°C. 24 h. After the reaction is over, cool naturally, filter with suction, wash with deionized water and ethanol until neutral, and remove soluble matter. The final product was dried in a vacuum oven at 60 °C for 6 h to obtain MoS 2 Body material.

[0030] Weigh KF (2.788g) and dissolv...

Embodiment 2

[0033] Weigh 2.42g (0.01mol) sodium molybdate (Na 2 MoO 4 .2H 2 O), dissolved in 30 mL of deionized water, and ultrasonically dispersed for 30 minutes. Another weighed 3.05g (0.04mol) thiourea [(NH 2 ) 2 CS], dissolved in 30 mL of deionized water, was also ultrasonically dispersed for 30 min. The thiourea aqueous solution was added dropwise into the sodium molybdate aqueous solution, and the mixed solution was ultrasonically dispersed for 30 minutes. After the ultrasonication, the mixed aqueous solution was fixed to 80mL and transferred to a 100mL polytetrafluoroethylene-lined high-pressure hydrothermal reactor, the reactor was sealed, and then placed in a constant temperature box and heated to 200°C. 24 h. After the reaction is over, cool naturally, filter with suction, wash with deionized water and ethanol until neutral, and remove soluble matter. The final product was dried in a vacuum oven at 60 °C for 6 h to obtain MoS 2 Body material.

[0034] Weigh NaF (2.015 g...

Embodiment 3

[0037] Weigh 2.42g (0.01mol) sodium molybdate (Na 2 MoO 4 .2H 2 O), dissolved in 30 mL of deionized water, and ultrasonically dispersed for 30 minutes. Another weighed 3.05g (0.04mol) thiourea [(NH 2 ) 2 CS], dissolved in 30 mL of deionized water, was also ultrasonically dispersed for 30 min. The thiourea aqueous solution was added dropwise into the sodium molybdate aqueous solution, and the mixed solution was ultrasonically dispersed for 30 minutes. After the ultrasonication, the volume of the mixed aqueous solution was adjusted to 80mL and transferred to a 100mL polytetrafluoroethylene-lined high-pressure hydrothermal reactor, the reactor was sealed, and then heated to 210°C in an incubator to react. 22h. After the reaction is over, cool naturally, filter with suction, wash with deionized water and ethanol until neutral, and remove soluble matter. The final product was dried in a vacuum oven at 60 °C for 6 h to obtain MoS 2 Body material.

[0038] Weigh NaF (2.700 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com