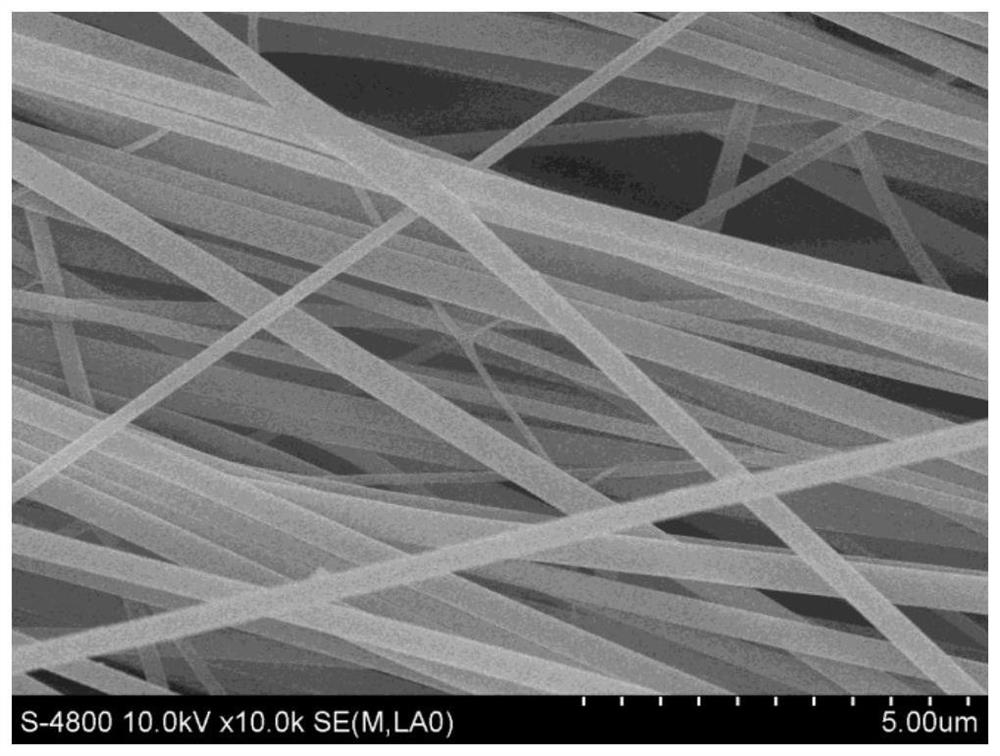

Amino and amidoxime polyacrylonitrile nanofiber as well as preparation method and application thereof

A technology of amino-based polyacrylonitrile and polyacrylonitrile, applied in chemical instruments and methods, other chemical processes, conjugated synthetic polymer artificial filaments, etc., can solve the problem of poor uniformity of polyacrylonitrile fiber functionalization reaction and functionalization Problems such as low reaction efficiency and high bulkiness of polyacrylonitrile fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

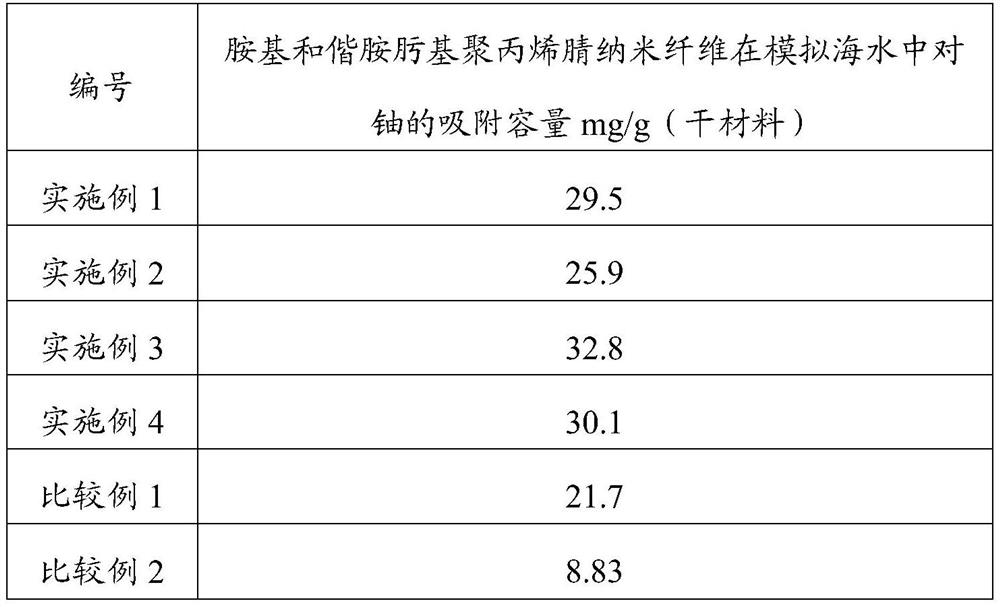

Embodiment 1

[0044] (1) Add 4.0 parts by weight of dry polyacrylonitrile powder to 21.0 parts by weight of dimethyl sulfoxide, stir at 50°C for 3 hours, and prepare polyacrylonitrile solution I; add 16.0 parts by weight of triethylenetetramine to 21.0 parts by weight of dimethyl sulfoxide, stirred for 1 h, and prepared as triethylene tetramine solution; mixed the above polyacrylonitrile solution I and triethylene tetramine solution, stirred and reacted at 110 ° C for 4 h, and obtained aminopolypropylene Nitrile spinning solution;

[0045] (2) Add 4.0 parts by weight of polyacrylonitrile powder to 23.0 parts by weight of dimethyl sulfoxide, stir at 50°C for 3 hours, and prepare polyacrylonitrile solution II; add 2.0 parts by weight of hydroxylamine hydrochloride to 23.0 parts by weight of In methyl sulfoxide, stir at 70°C for 2 hours to prepare hydroxylamine hydrochloride solution; mix the above polyacrylonitrile solution II and hydroxylamine hydrochloride solution, then add 1.5 parts by we...

Embodiment 2

[0048] (1) Add 4.0 parts by weight of dry polyacrylonitrile powder to 15.0 parts by weight of dimethylformamide, stir at 70°C for 1 hour, and prepare polyacrylonitrile solution I; add 10.0 parts by weight of tetraethylenepentamine to 15.0 parts by weight of dimethyl sulfoxide, stirred for 2 hours, and prepared into tetraethylenepentamine solution; mixed the above-mentioned polyacrylonitrile solution I and tetraethylenepentamine solution, stirred and reacted at 120°C for 2 hours, and obtained amino-based polypropylene Nitrile spinning solution;

[0049] (2) Add 3.0 parts by weight of polyacrylonitrile powder to 20.0 parts by weight of dimethylformamide, stir at 50°C for 2 hours, and prepare polyacrylonitrile solution II; add 2.0 parts by weight of hydroxylamine hydrochloride to 20.0 parts by weight of In methyl sulfoxide, stir at 75°C for 1 hour to prepare hydroxylamine hydrochloride solution; mix the above polyacrylonitrile solution II and hydroxylamine hydrochloride solution,...

Embodiment 3

[0052] (1) Add 4.5 parts by weight of dry polyacrylonitrile powder to 20.0 parts by weight of dimethyl sulfoxide, stir at 50°C for 2 hours, and prepare polyacrylonitrile solution I; add 17.0 parts by weight of triethylenetetramine to 20.0 parts by weight of dimethyl sulfoxide, stirred for 2 hours, and prepared as a triethylenetetramine solution; mixed the above-mentioned polyacrylonitrile solution I and triethylenetetramine solution, stirred and reacted at 120°C for 2 hours, and obtained aminopolypropylene Nitrile spinning solution;

[0053] (2) Add 4.5 parts by weight of polyacrylonitrile powder to 23.5 parts by weight of dimethyl sulfoxide, stir at 70°C for 1 hour, and prepare polyacrylonitrile solution II; add 2.5 parts by weight of hydroxylamine hydrochloride to 23.5 parts by weight of In methyl sulfoxide, stir at 80°C for 1 hour to prepare hydroxylamine hydrochloride solution; mix the above polyacrylonitrile solution II and hydroxylamine hydrochloride solution, then add 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com