Digital twinning-based robot production line operation system construction method, system and equipment

A production line equipment and operating system technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of large space occupation, high power consumption, long operating system delay, etc., to achieve rich functions, improve performance, The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

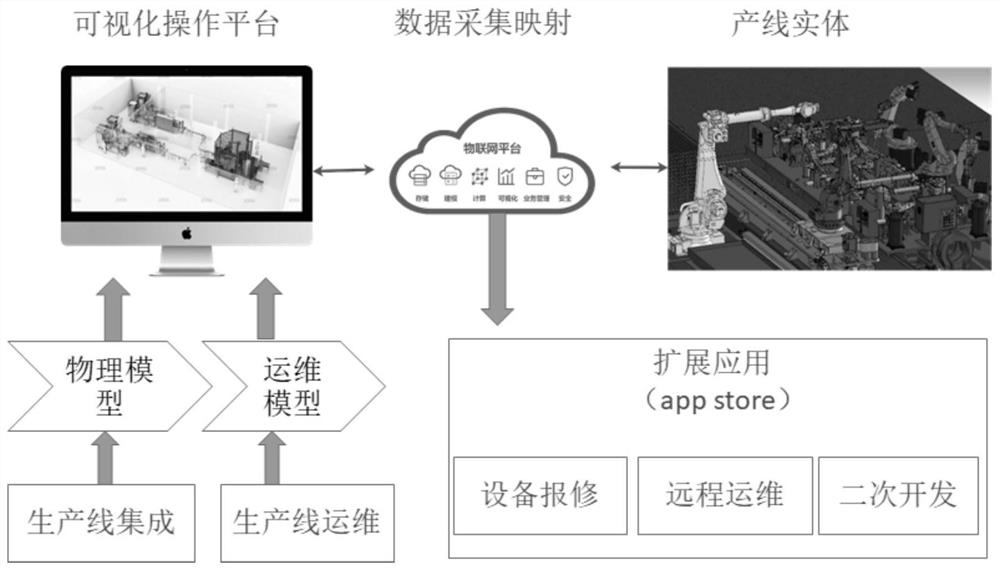

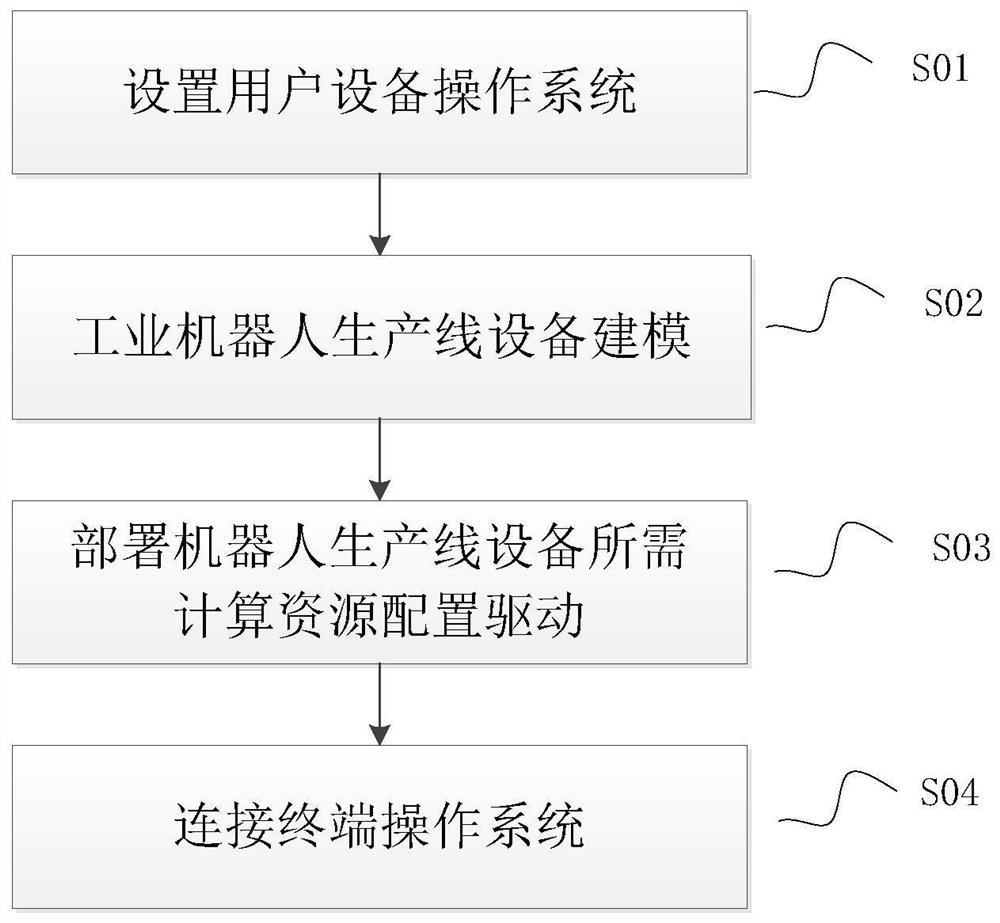

[0032] First, refer to figure 1 , the digital twin-based robot production line operating system construction method described in the present invention includes a cloud platform and robot production line equipment in its application scenarios. Among them, the cloud platform is located in the cloud, and a large number of distributed robot production line equipment is located on the user end, and the data interaction between the cloud platform and the robot production line equipment is realized through the Internet. In some specific implementations, it may also involve users using their user equipment through the cloud platform and robot production line equipment, so the application scenario may also include user equipment. In addition, it should be noted that in the subsequent embodiments, the robot production line equipment involved in the control interaction process between the cloud platform and the robot production line equipment can be understood as any one of a large numbe...

Embodiment 2

[0053] Based on the same inventive concept of the embodiment, this embodiment provides a cloud platform-based IoT device control system, including a cloud platform and robot production line equipment, wherein:

[0054] The cloud platform is provided with a cloud operating system configured to deploy computing resources required for the work of the robot production line equipment, and correspondingly configures drivers for the computing resources in the cloud operating system;

[0055] The robot production line equipment invokes the computing resource through a driver program in the cloud operating system.

[0056] As an optional embodiment, the system further includes: user equipment;

[0057] The cloud platform is further configured to build an application program store for the user equipment to upload or download application programs; wherein, the service corresponding to the application program is implemented through the IoT device;

[0058] The user equipment installed wi...

Embodiment 3

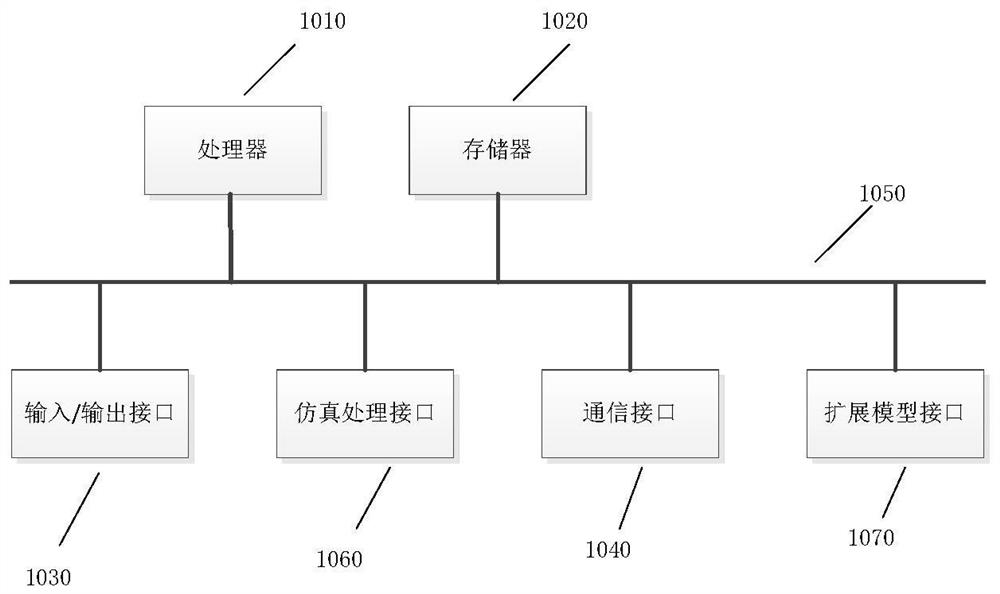

[0061] Based on the same inventive concept, the present invention also provides an electronic device, including a memory, a processor, and a computer program stored in the memory and operable on the processor. When the processor executes the program, any one of the above The construction method of the robot production line operating system based on the digital twin technology described in the embodiment.

[0062] image 3 A schematic diagram of the hardware structure of the electronic device is shown, and the device may include: a processor 1010 , a memory 1020 , an input / output interface 1030 , a communication interface 1040 and a bus 1050 . The processor 1010 , the memory 1020 , the input / output interface 1030 and the communication interface 1040 are connected to each other within the device through the bus 1050 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com