Vibration plate and sound production device

A technology of sound-generating device and vibrating plate, applied in the direction of flat diaphragm, fiber diaphragm, polymer material diaphragm, etc., can solve the problems of low high-frequency cut-off frequency, narrow frequency response range, small density, etc. Wide-ranging, low-density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

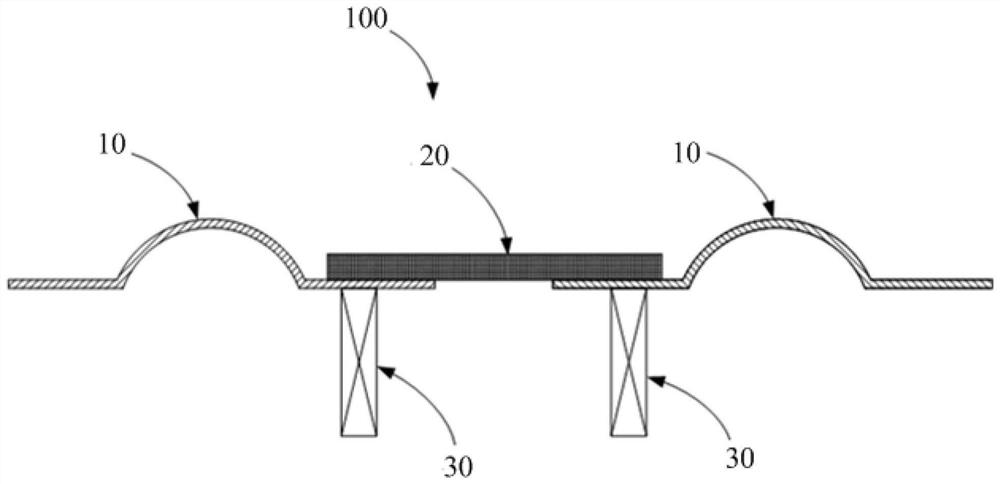

[0062] It should be noted that the vibrating plate of the present invention can be prepared by the following steps:

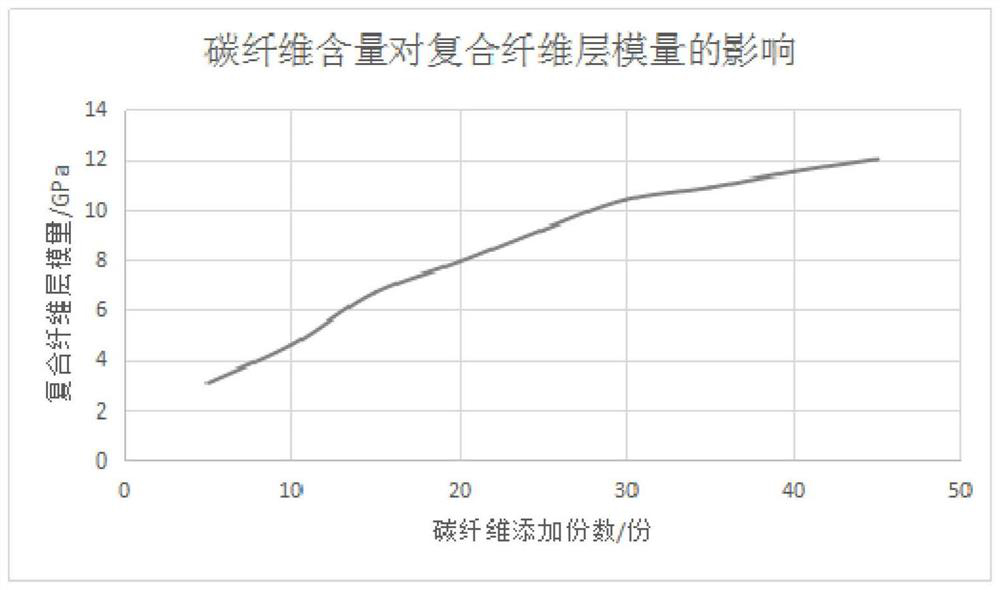

[0063] Firstly, polymer fiber and carbon fiber are dispersed in a solvent, mixed evenly, and the solvent is removed to obtain a composite fiber material. Wherein, based on 100 parts of the total mass of the composite fiber, the content of the polymer fiber is 50-90 parts, and the content of the carbon fiber is 5-50 parts. Here the solvent can be water or an organic solvent, and the organic solvent can be one of methanol, ethanol, isopropanol, acetone, methyl ethyl ketone, ethyl acetate, butyl acetate, n-hexane, cyclohexane, sherwood oil, toluene or Various mixes.

[0064] Secondly, the composite fiber material is placed in a hot-pressing mold, and the cone-shaped composite fiber layer is hot-pressed at a hot-pressing temperature of 180°C-200°C.

[0065] At the same time, the foam material is cut into shape, placed in a hot-pressing mold, and subjected to hot-...

Embodiment 1

[0073] The vibrating plate of this embodiment is prepared by the following steps:

[0074] 1. By mass, weigh 100 parts of polymer fibers with a diameter of 10 μm, cut them into short fibers with a length of 20mm-40mm, and disperse them in 400 parts of ethanol solvent, and stir to make them evenly dispersed.

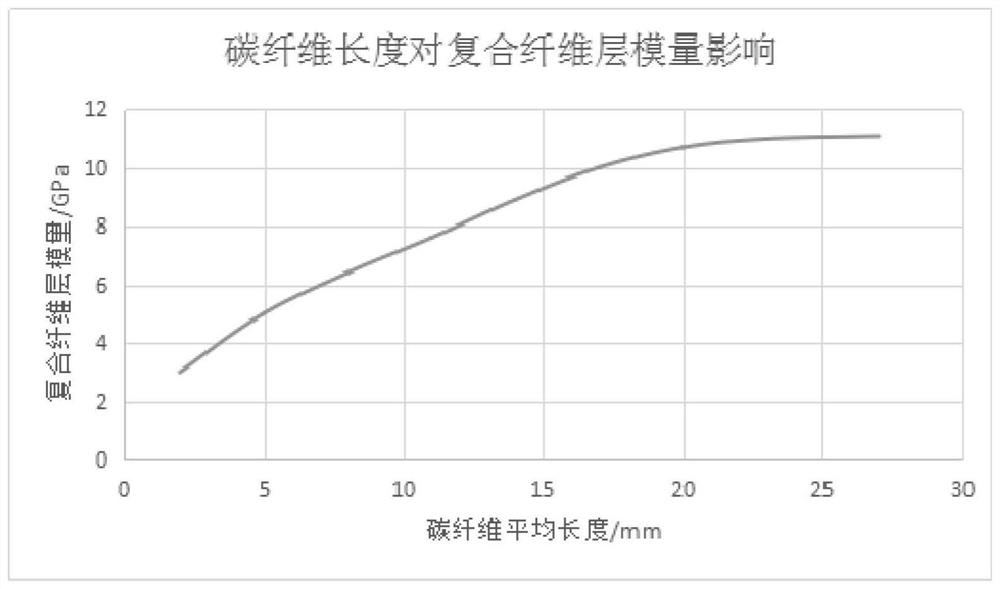

[0075] 2. Weigh 40 parts of carbon fibers with a diameter of 7 μm, cut them into short fibers with an average length of 20 mm, add them to the above-mentioned ethanol solvent, and continue to stir so that the two fibers are evenly dispersed in the ethanol solvent.

[0076] 3. The two kinds of fibers are removed from the ethanol solvent, and after the ethanol solvent is removed by drying, a composite fiber material uniformly composited between carbon fiber and polymer fiber is obtained, and the composite fiber material has a three-dimensional network structure.

[0077] 4. Put the composite fiber material in the mold, and perform hot-press molding at a temperature of 190°C...

Embodiment 2

[0082] The carbon fibers in Example 1 were treated with a coupling agent, and other steps were the same as those in Example 1.

[0083] The specific steps of carbon fiber treated by coupling agent are as follows:

[0084] First, take 10 parts of the coupling agent and add it into a blended solvent of 100 parts of water and 900 parts of ethanol, and fully stir to obtain a pretreatment agent.

[0085] Then take 40 parts of carbon fibers with a diameter of 7 μm, cut them into short fibers with an average length of 20 mm, add them to the above pretreatment agent, stir them thoroughly, and let them stand for 4 hours.

[0086] Then the treated carbon fibers are filtered out and dried to obtain surface-treated carbon fibers.

[0087] It should be noted that the coupling agent here can be selected from one of KH-540, KH-550, KH-560, KH-570, KH-590, KH-792, Si-602, Si-563, and A-151 or more. Moreover, based on 100 parts by mass of the blended solvent, the amount of the coupling agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com