Diamond coating cutter device for metal surface nanocrystallization and preparation method of diamond coating cutter device

A diamond coating and metal surface technology, which is applied in lathe tools, metal material coating technology, metal processing equipment, etc., can solve problems such as increased surface roughness of workpieces, increased surface roughness, and limited application fields , to achieve low friction coefficient, low cost, and expand the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] In this embodiment, the preparation method of the diamond-coated cutting tool device for metal surface nanometerization is as follows:

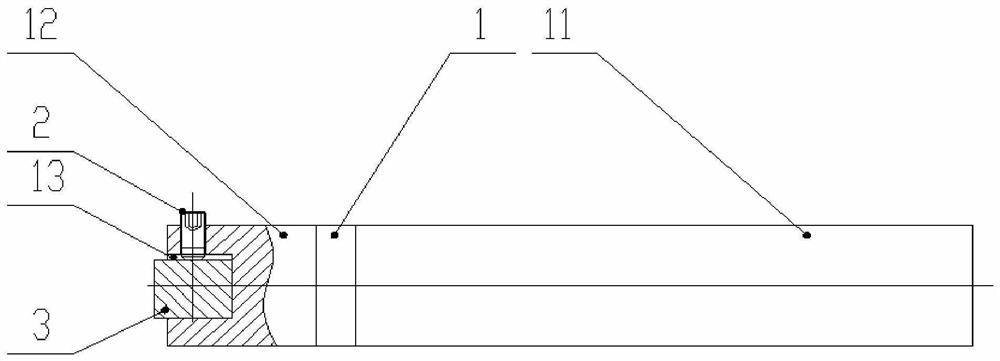

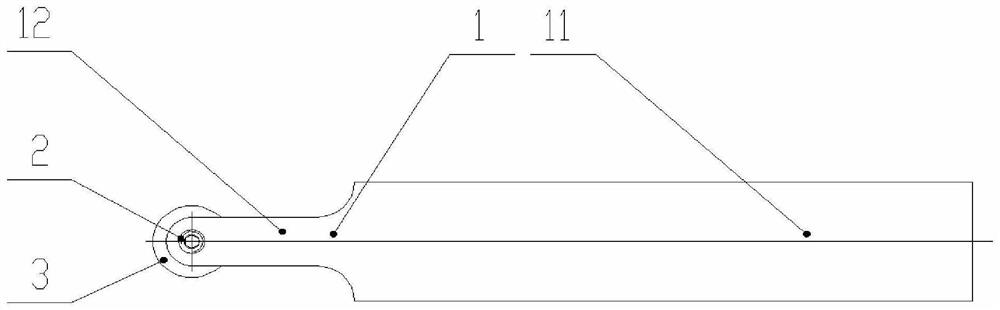

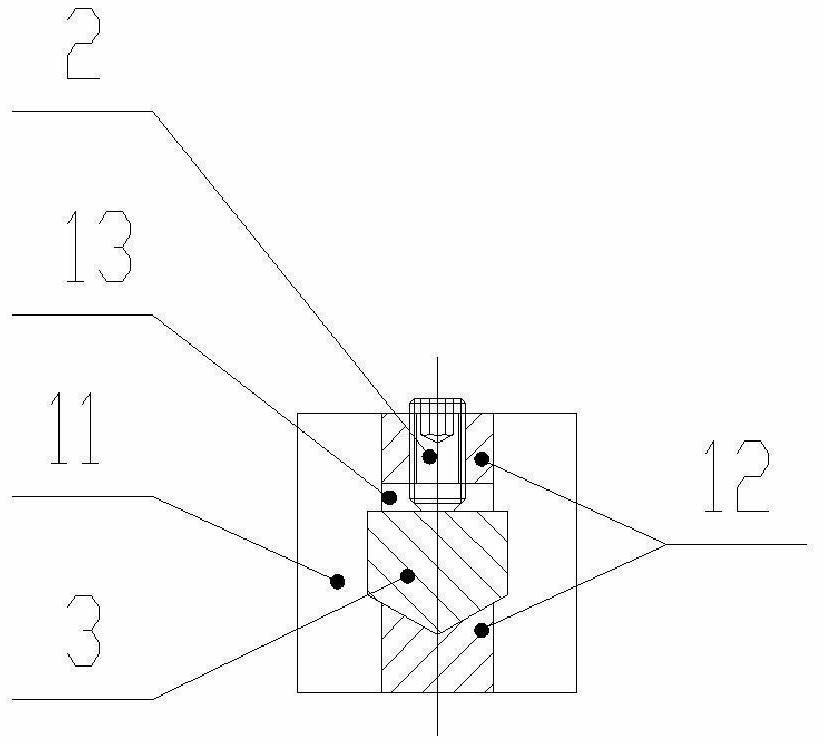

[0041] Firstly, take YG6 tungsten carbide finely ground round rod as the substrate, and obtain the required tool substrates of various specifications and sizes through wire cutting machine processing, and process one end of the YG6 tungsten carbide finely ground round rod into a wedge-shaped section, and one end of the wedge-shaped section The integral connection with the cylindrical section is circular, and the other end of the wedge-shaped section is a bilaterally symmetrical inclined plane that intersects at the diameter of one end of the round rod to form a tip, forming a tool base with a combined upper and lower structure of the cylindrical section and the wedge-shaped section. Then, after surface treatment, a 10 μm polycrystalline diamond coating is deposited on the cylindrical surface of the tool substrate (ie, the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com