Photo-thermal curing resin composition as well as preparation method and application thereof

A resin composition, photothermal curing technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of wear resistance and strength that are difficult to meet actual needs, isobornyl big smell, high cost compatibility, etc., to achieve High hardness and wear resistance, sufficient curing, enhanced hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

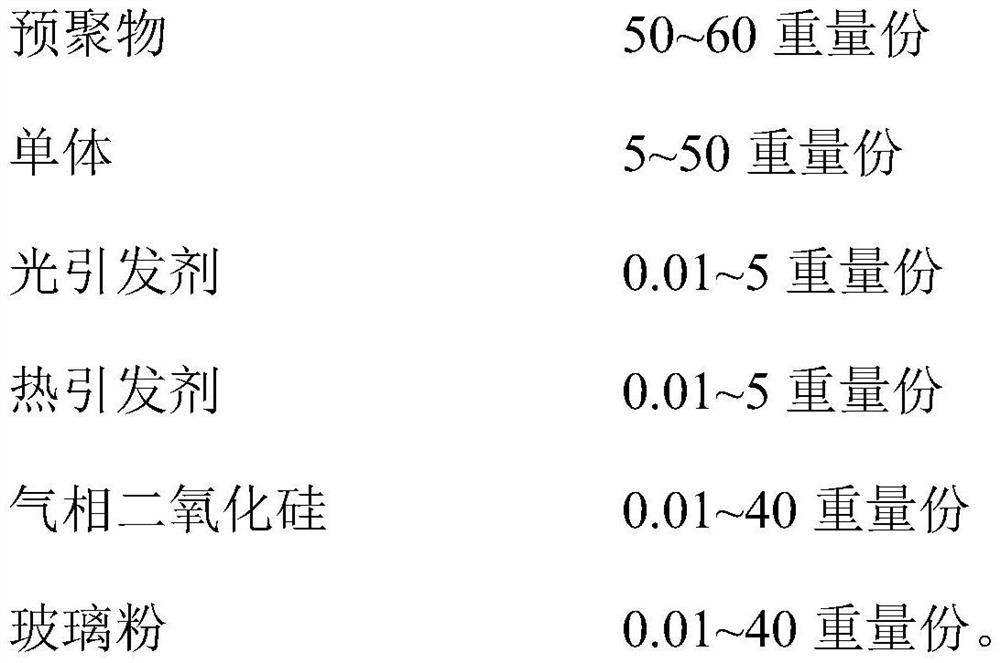

[0068] A photothermally curable resin composition, the resin composition comprises the following components in parts by weight:

[0069]

[0070]

[0071] The preparation method of the numerical composition provided in this embodiment comprises the following steps:

[0072] (1) Triethylene glycol dimethacrylate, phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide, dibenzoyl peroxide, defoamer BYK-067A, stearic acid Mix zinc, iron oxide red, iron oxide yellow and titanium dioxide at 50°C for 2 hours to obtain a mixed monomer;

[0073] (2) mixing the mixed monomers obtained in step (1), urethane dimethacrylate and bisphenol A-glycidyl dimethacrylate at 50° C. for 2 hours to obtain a mixed resin;

[0074] (3) The mixed resin obtained in step (2), fumed silica R711, barium-containing glass powder Nano with a particle size of 0.4 μm 0.4 and 0.7 μm barium-containing glass powder Nano 0.7 Mix at 50° C. for 2 hours to obtain the resin composition.

Embodiment 2

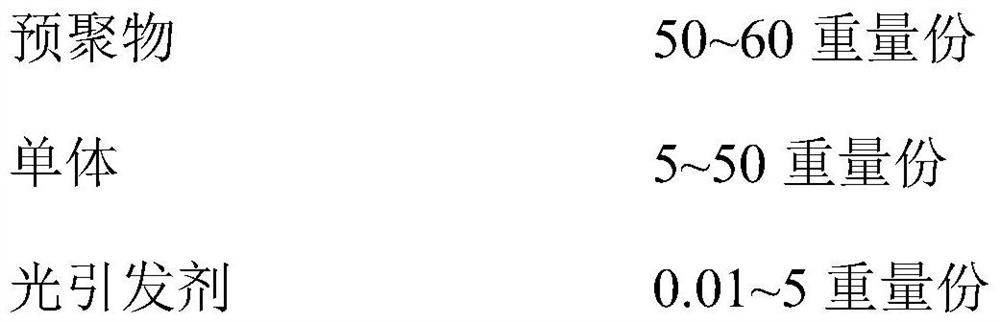

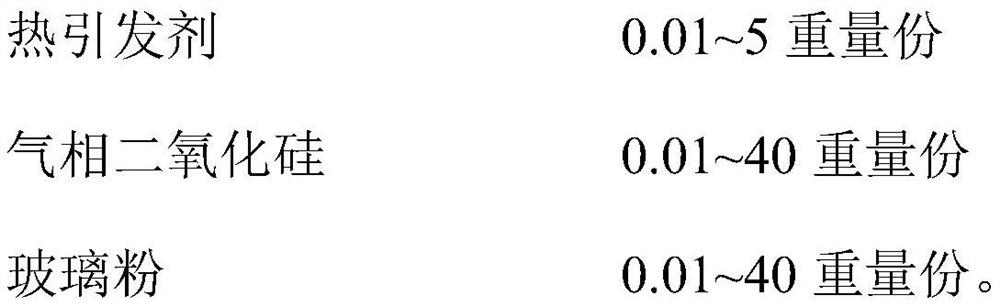

[0076] A photothermally curable resin composition, the resin composition comprises the following components in parts by weight:

[0077]

[0078]

[0079] The preparation method of the resin composition provided in this example is the same as that in Example 1.

Embodiment 3

[0081] A photothermally curable resin composition, the resin composition comprises the following components in parts by weight:

[0082]

[0083]

[0084] The preparation method of the resin composition provided in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Water absorption value | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com