Automobile oil filter sealing ring and production process thereof

An oil filter and sealing ring technology, applied in the field of filters, can solve the problems of short service life and poor mechanical performance of the sealing ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

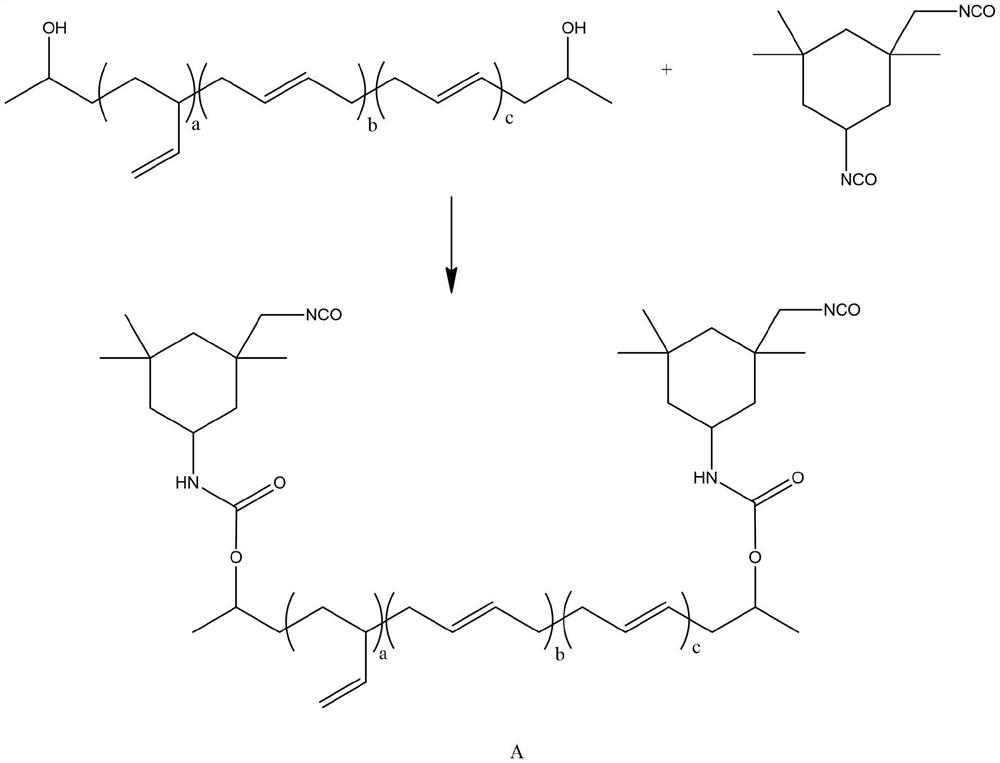

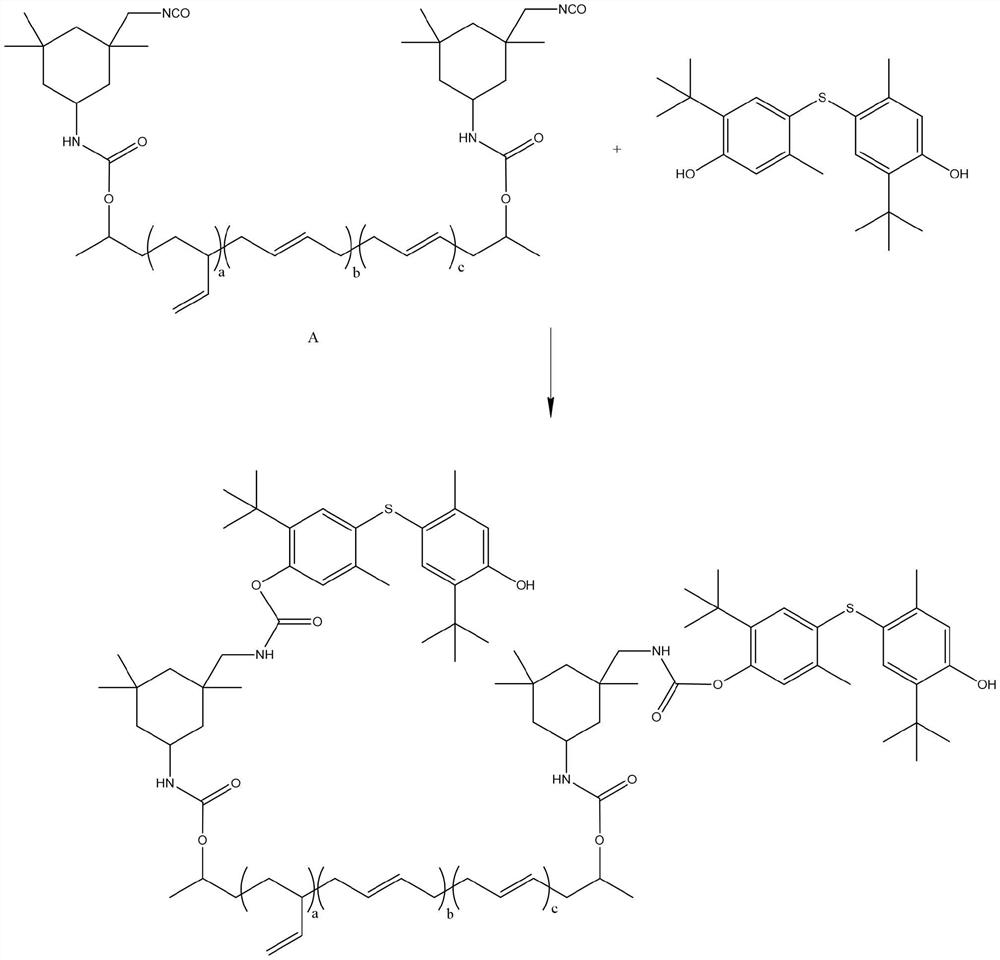

Method used

Image

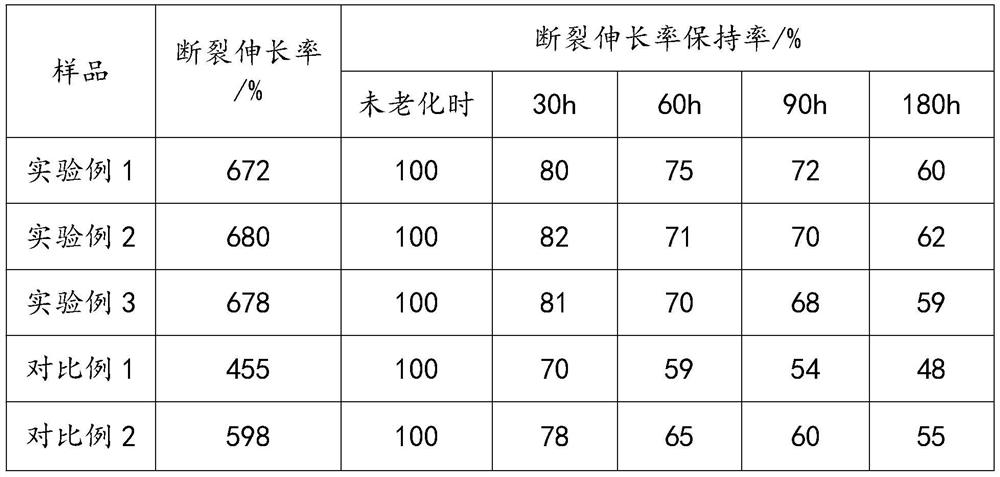

Examples

Embodiment 1

[0042] The present embodiment is a sealing ring of an automobile oil filter, comprising the following components in parts by weight:

[0043] 90 parts of modified rubber, 1 part of zinc pyrithione, 1 part of tetrabutylammonium bromide, 1 part of propylene alcohol, 1 part of ditetradecyl alcohol ester, 1 part of aluminum hydroxide, 5 parts of attapulgite, polybromide 2 parts of styrene, 2 parts of antimony trioxide, 1 part of dicumyl peroxide, 10 parts of filler and 5 parts of anti-aging agent;

[0044]The automobile oil filter sealing ring is prepared by the following steps:

[0045] S1: put the modified rubber into an internal mixer for internal mixing, add zinc pyrithione, tetrabutylammonium bromide, propylene alcohol, ditetradecyl alcohol ester and aluminum hydroxide, and knead to obtain material A;

[0046] S2: adding attapulgite, polystyrene bromide, antimony trioxide, anti-aging agent, dicumyl peroxide and filler into material A, mixing, debinding and cooling to obtain ...

Embodiment 2

[0057] The present embodiment is a sealing ring of an automobile oil filter, comprising the following components in parts by weight:

[0058] 100 parts of modified rubber, 2 parts of zinc pyrithione, 2 parts of tetrabutylammonium bromide, 2 parts of propylene alcohol, 1 part of ditetradecyl alcohol ester, 1 part of aluminum hydroxide, 5 parts of attapulgite, polybromide 2 parts of styrene, 2 parts of antimony trioxide, 1 part of dicumyl peroxide, 10 parts of filler and 5 parts of anti-aging agent;

[0059] The automobile oil filter sealing ring is prepared by the following steps:

[0060] S1: put the modified rubber into an internal mixer for internal mixing, add zinc pyrithione, tetrabutylammonium bromide, propylene alcohol, ditetradecyl alcohol ester and aluminum hydroxide, and knead to obtain material A;

[0061] S2: adding attapulgite, polystyrene bromide, antimony trioxide, anti-aging agent, dicumyl peroxide and filler into material A, mixing, debinding and cooling to ob...

Embodiment 3

[0072] The present embodiment is a sealing ring of an automobile oil filter, comprising the following components in parts by weight:

[0073] 100 parts of modified rubber, 1 part of zinc pyrithione, 1 part of tetrabutylammonium bromide, 1 part of propylene alcohol, 1 part of ditetradecyl alcohol ester, 2 parts of aluminum hydroxide, 6 parts of attapulgite, polybromide 3 parts of styrene, 3 parts of antimony trioxide, 2 parts of dicumyl peroxide, 20 parts of filler and 15 parts of anti-aging agent;

[0074] The automobile oil filter sealing ring is prepared by the following steps:

[0075] S1: put the modified rubber into an internal mixer for internal mixing, add zinc pyrithione, tetrabutylammonium bromide, propylene alcohol, ditetradecyl alcohol ester and aluminum hydroxide, and knead to obtain material A;

[0076] S2: adding attapulgite, polystyrene bromide, antimony trioxide, anti-aging agent, dicumyl peroxide and filler into material A, mixing, debinding and cooling to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com