Hydrophobic coating and air conditioner water pan comprising same

A hydrophobic and coating technology, applied in the direction of coating, condensate prevention, liquid chemical plating, etc., can solve the problems of self-cleaning, dust accumulation, microbial enrichment and other problems in the air-conditioning water tray, and achieve good self-cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

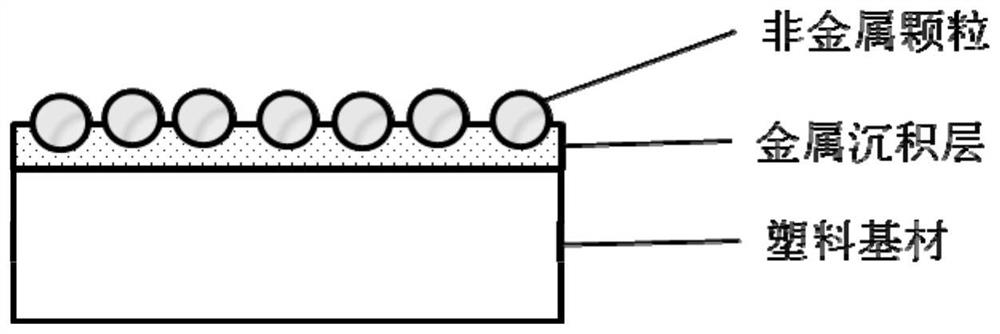

[0036] An embodiment of the present invention provides a method for preparing a hydrophobic coating according to any of the above embodiments, the preparation method includes: substrate pretreatment and electroless plating, the substrate pretreatment includes substrate roughening, base Material sensitization, colloidal palladium activation and degumming.

[0037] In the preferred embodiment above, the base material can be selected from various plastics such as ABS plastic, PPO modified polyphenyloxy resin, PA polyamide, POM polyacetal resin, PBT polybutylene terephthalate; Treatment can choose high chromium anhydride solution, sulfuric acid; substrate sensitization treatment can choose stannous chloride solution, hydrochloric acid solution, dilute sulfuric acid solution; colloidal palladium activation can choose palladium chloride, palladium nitrate, palladium sulfate, palladium phosphate; Hydrochloric acid solution, phosphoric acid, sulfuric acid, and nitric acid can be used....

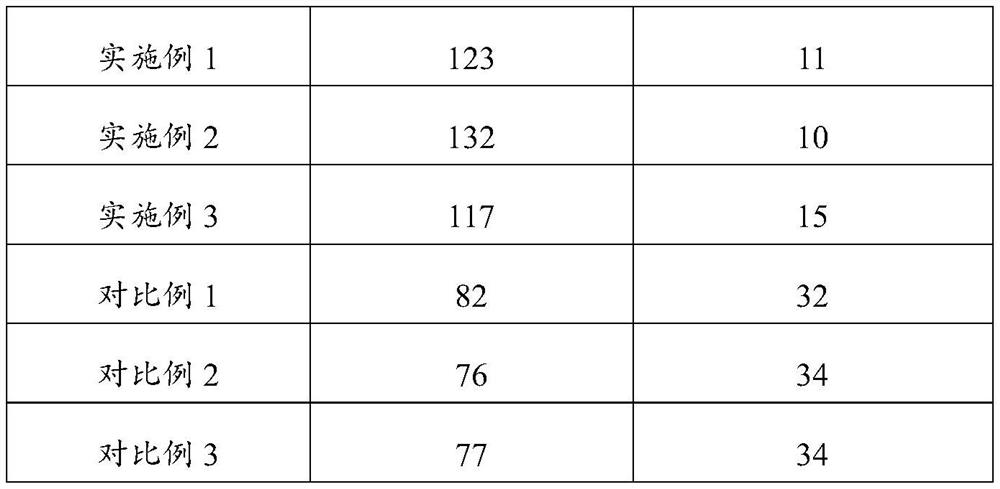

Embodiment 1

[0056] The present embodiment provides a kind of hydrophobic coating, and its preparation method is specifically as follows:

[0057] (1) Substrate pretreatment:

[0058] Choose ABS plastic as the base material, roughen with perchromic anhydride solution, sensitize with a solution of 40g / L stannous chloride and 100ml / L hydrochloric acid, activate with palladium chloride, and then use 100ml / L hydrochloric acid solution at 45 Under the condition of ℃, treat for 30s to debond, and make a platable plastic substrate;

[0059] (2) Electroless plating:

[0060] Carry out the preparation of electroless plating solution according to following formula, concrete formula is:

[0061] NiSO 4 ·6H 2 O, 20g / L, NaH 2 PO 2 ·6H 2 O, 35g / L, hydrophobic silica (2μm) treated with cationic surfactant, 5g / L, glycine, appropriate amount, lactic acid, 15ml / L, propionic acid, 10ml / L;

[0062] Prepare the electroless plating solution at 90°C according to the above formula, and adjust the pH to 4....

Embodiment 2

[0066] The present embodiment provides a kind of hydrophobic coating, and its preparation method is specifically as follows:

[0067] (1) Substrate pretreatment:

[0068] Choose ABS plastic as the base material, roughen with perchromic anhydride solution, sensitize with a solution of 40g / L stannous chloride and 100ml / L hydrochloric acid, activate with palladium chloride, and then use 50ml / L sulfuric acid solution at 45 Under the condition of ℃, treat for 30s to debond, and make a platable plastic substrate;

[0069] (2) Electroless plating:

[0070] Carry out the preparation of electroless plating solution according to following formula, concrete formula is:

[0071] NiSO 4 ·6H 2 O, 15g / L, NaH 2 PO 2 ·6H 2 O, 35g / L, silicone powder (1μm) treated with cationic surfactant, 4g / L, glycine, appropriate amount, lactic acid, 15ml / L, propionic acid, 10ml / L;

[0072] Prepare the electroless plating solution at 90°C according to the above formula, and adjust the pH to 4.5;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com