Preparation method and application of nano-particle functionalized artificial spider silk

A nanoparticle and spider silk technology, applied in textiles and papermaking, fiber treatment, light-resistant fibers, etc., can solve the problems that the toughness cannot meet the industrial needs, the fiber has a single function, and does not have light-to-heat conversion, etc., and the functional method is simple The effect of high efficiency, uniform particle size, and strong durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This example relates to a method for preparing artificial spider silk functionalized with copper sulfide nanoparticles, and the specific steps include:

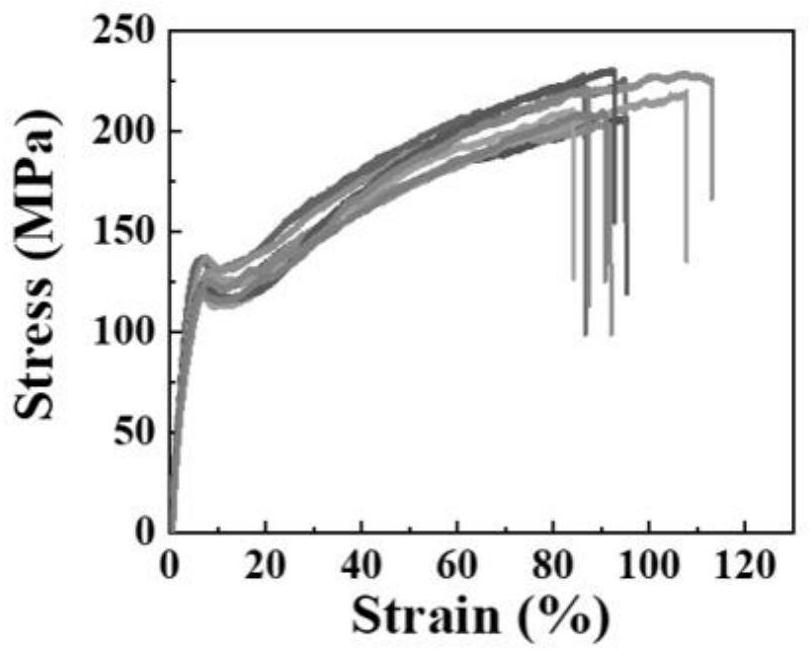

[0038] 1) The primary fiber of the recombinant spider silk protein is soaked in water for 2 minutes and begins to elongate and become soft, the degree of freedom of the molecular chain increases, and it is stretched to 6 times its original length in water.

[0039] The primary fiber of recombinant spider silk protein is obtained by wet spinning of high-concentration spinning solution of recombinant spider silk protein, specifically: sucking high-concentration spinning solution of recombinant spider silk protein into a syringe, and using a syringe pump to pass it through The microfluidic chip was extruded into a 90% ethanol (pH5.0) coagulation bath to dehydrate and solidify the recombinant spider silk protein into nascent fibers.

[0040] The high-concentration spinning solution of recombinant spider silk protein, that ...

Embodiment 2

[0050] This example relates to a method for preparing artificial spider silk functionalized with cadmium sulfide quantum dots. The specific steps include:

[0051] 1) The primary fiber of the recombinant spider silk protein is soaked in water for 2 minutes and begins to elongate and become soft, the degree of freedom of the molecular chain increases, and it is stretched to 6 times its original length in water.

[0052] 2) The fiber stretched in water was placed in 1 mM cadmium chloride solution, and soaked at room temperature for 12 hours.

[0053] 3) Put the treated fiber in 3mM sodium sulfide solution and treat it at room temperature for 6h. After the treatment, the fiber was taken out and dried overnight at room temperature to obtain artificial spider silk functionalized with cadmium sulfide quantum dots.

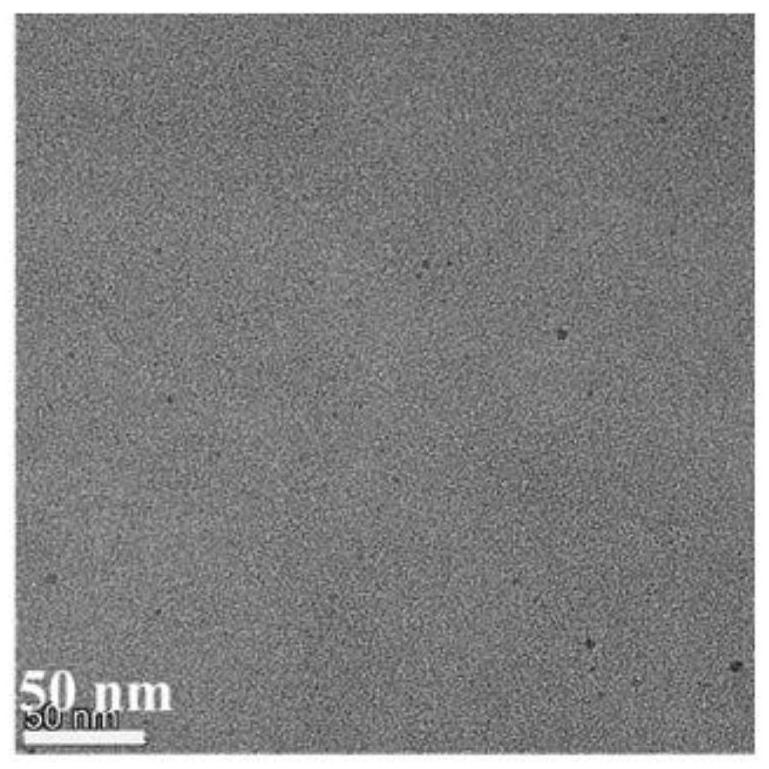

[0054] Compared with the existing method of functionalizing spider silk by directly soaking the quantum dot dispersion solution, the strength of the cadmium sulfide qua...

Embodiment 3

[0056] This embodiment relates to a preparation method of gold nanoparticle functionalized artificial spider silk, and the specific steps include:

[0057] 1) The primary fiber of the recombinant spider silk protein is soaked in water for 2 minutes and begins to elongate and become soft, the degree of freedom of the molecular chain increases, and it is stretched to 6 times its original length in water.

[0058] 2) The fibers stretched in water were placed in 0.8 mM chloroauric acid solution, and soaked at room temperature for 12 hours.

[0059] 3) Put the treated fiber in 8mM sodium citrate solution and treat at 75°C for 6h. After the treatment, the fibers were taken out and dried overnight at room temperature to obtain artificial spider silk functionalized with gold nanoparticles.

[0060] Compared with the existing method of synthesizing nanoparticles in situ on regenerated fibers by redox reaction, the gold nanoparticles synthesized in this example have a uniform particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com