Cr-based MOF carbon material catalyst co-doped with loaded nano-palladium particles, preparation of Cr-based MOF carbon material catalyst and application of catalyst in hydrogen production from formic acid

A nano-palladium and co-doping technology, applied in the direction of physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, hydrogen, etc., can solve the problems of poisoned catalysts and achieve the effect of solving the aggregation of metal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

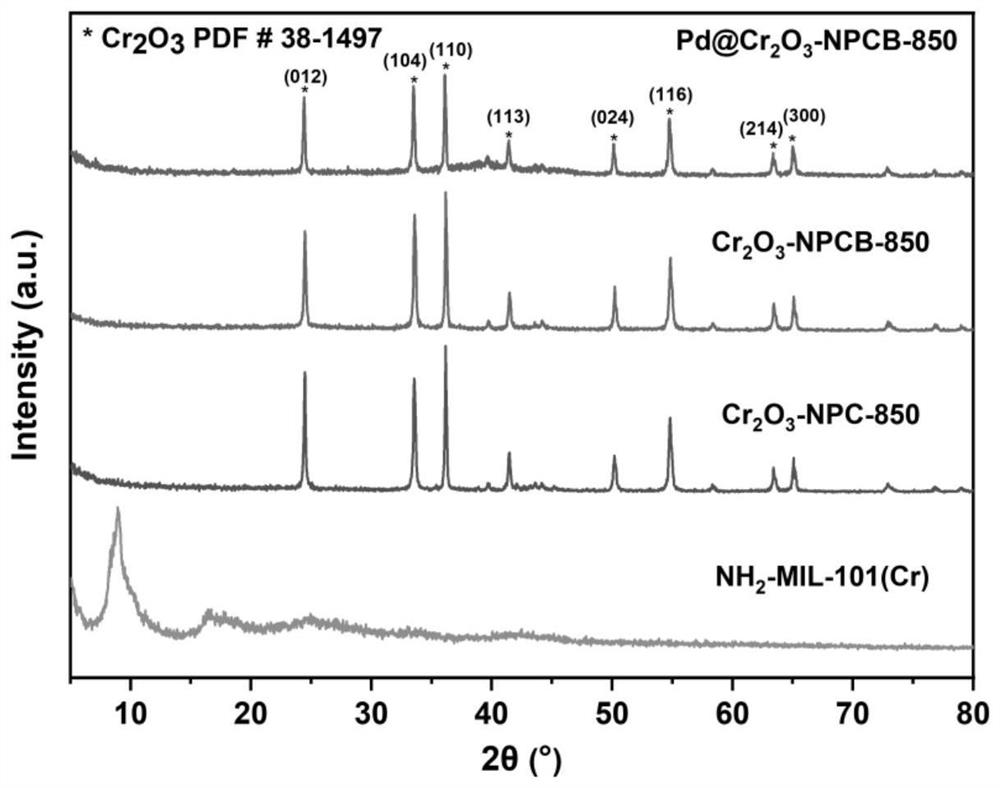

[0043] (1) During the preparation process, in order to improve the solubility of the organic ligands in the solvent, NaOH was used as the MOF synthesis regulator. First, add 3.2000g Cr(NO 3 ) 3 9H 2 O and 60 mL of ultrapure water, magnetically stirred until the solids were completely dissolved; subsequently, 1.4400 g of 2-aminoterephthalic acid (NH 2 -HBDC), into which a chromium salt solution is injected. Next, add 0.6400g NaOH regulator under strong stirring, and use ultrasonic-stirring technology to fully mix the materials in the solvent; the solution turns gray-green, and ultrasonically disperses it in water for 30 minutes; then, the mixed material liquid Transfer to the polytetrafluoroethylene liner of the hydrothermal kettle, and place the hydrothermal kettle in a muffle furnace (programmed temperature rise rate 1°C / min) at a constant temperature of 150°C for 12h. After the temperature of the muffle furnace was slowly lowered to room temperature, the hydrothermal ket...

Embodiment 2

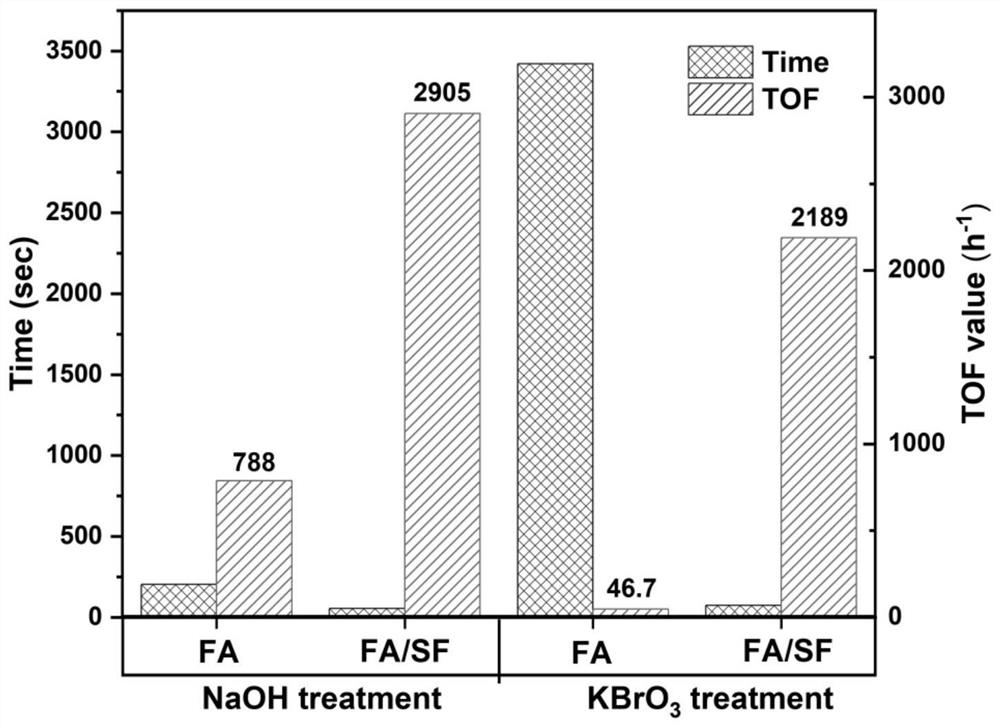

[0048] Example 1 was treated by two activation methods (5mol / L, 150°C NaOH solution or potassium bromate solution activation) and loaded with Pd metal to obtain Pd@Cr 2 o 3 -NPCB-850, take 50mg and put them into different flasks, set at 60°C, and after the system is stable for 5 minutes, inject 5mL of reaction liquid into the flask (the molar ratio of formic acid to sodium formate=1:3, formic acid 1mol / L; Or for formic acid 1mol / L), start stirring and start the mass flow meter. When the flow meter gas velocity is less than 5SCCM, stop the reaction and record the gas production. The experimental results found that the catalytic effect after NaOH treatment is the best, see figure 1 .

Embodiment 3-7

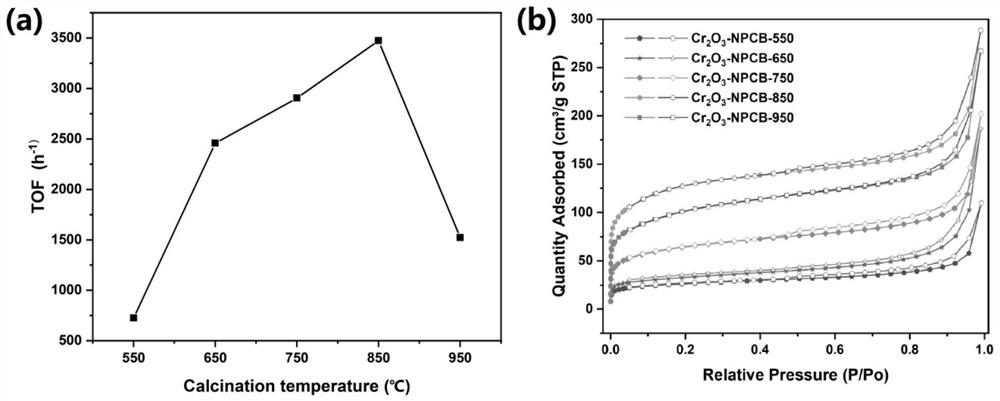

[0050] Referring to Example 1, the theoretical load of synthetic palladium is 10wt% Cr 2 o 3 -NPCB-T, (T represents the calcination temperature, and the parallel test temperatures are 550, 650, 750, 850, 950°C respectively). Pour 100mg of catalyst into the flask, set at 60°C, and after the system stabilizes for 5 minutes, inject 5mL of reaction solution into the flask (the molar ratio of formic acid to sodium formate = 1:3, formic acid 1mol / L), start stirring and start the mass flow count. When the flow meter gas velocity is less than 5SCCM, stop the reaction and record the gas production. It is found that under the same conditions, 850°C calcination has the best catalytic effect. For details, see figure 2 .

[0051] Table 1 Effect of carrier calcination temperature on hydrogen production from formic acid

[0052] Example 3 4 5 6 7 Calcination temperature / ℃ 550 650 750 850 950 TOF / h -1

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com