Preparation method of gold nanoparticles as electron microscope developer and obtained gold nanoparticles

A technology of nano-gold particles and developer, applied in nanotechnology, nanotechnology, nanotechnology and other directions for sensing, can solve the problems of inhomogeneous particle size of nano-gold particles, large product differences, and inability to large-scale preparation, etc. The effect of uniform appearance, uniform size and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

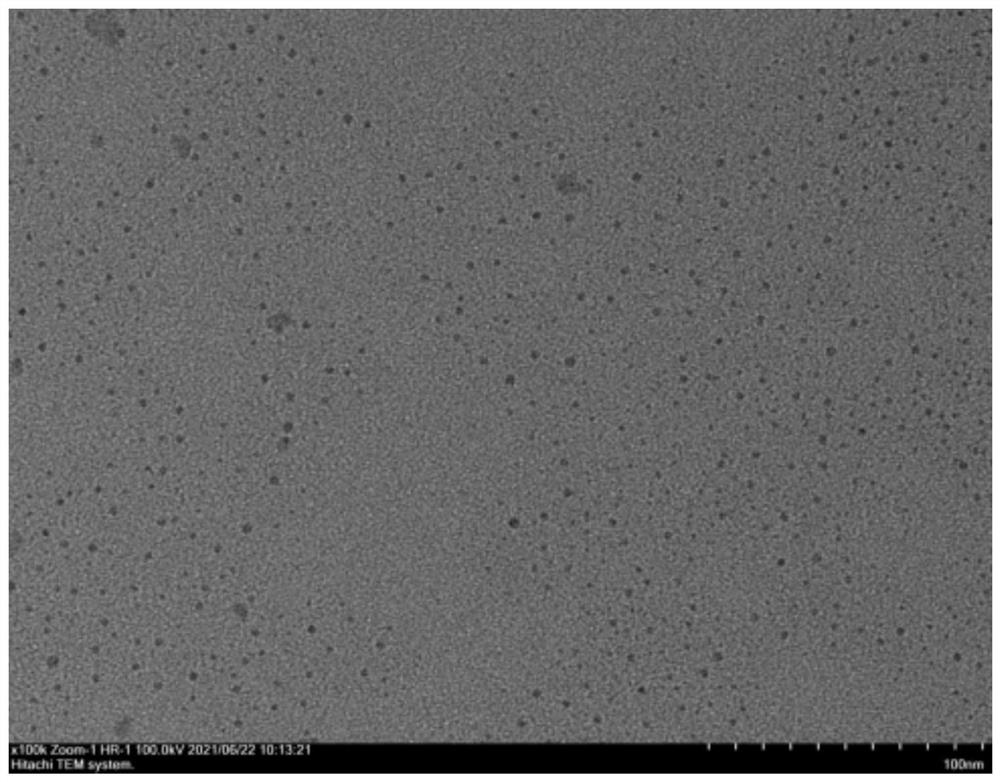

Embodiment 1

[0049] A preparation method of gold nanoparticles as electron microscope developer, specifically comprising the steps of:

[0050] Dissolve 1g of chloroauric acid in deionized water, prepare 25mM chloroauric acid solution, and store in the dark at 4°C; dissolve 1.822g (5mmol) cetyltrimethylammonium bromide in 98mL of deionized water to obtain Cetyltrimethylammonium bromide solution (i.e. stabilizer solution), get the 25mM chloroauric acid solution of 2mL in the cetyltrimethylammonium bromide solution, fully stir and mix to obtain the precursor solution, The mol ratio of cetyltrimethylammonium bromide and chloroauric acid in the precursor solution is 100:1;

[0051] After dissolving 37.83mg of sodium borohydride in 10mL of deionized water at 0°C, use a pipette gun to take 2mL of it and add it to 98mL of deionized water to obtain a sodium borohydride solution;

[0052] Precursor solution and sodium borohydride solution (the molar ratio of chloroauric acid in the precursor solut...

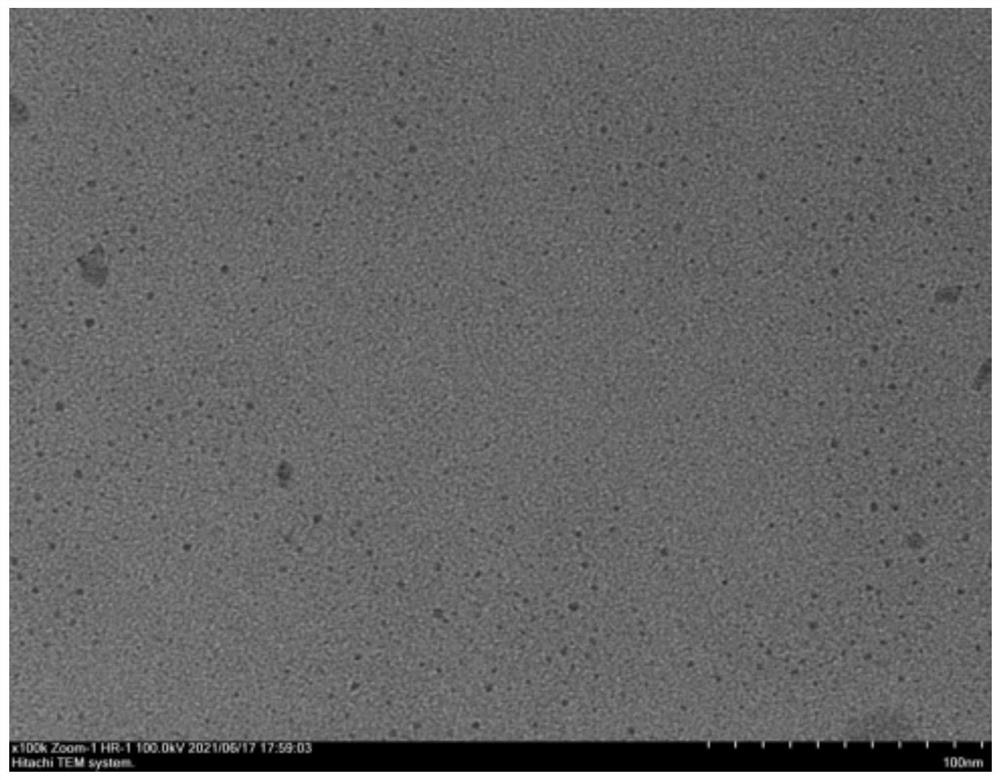

Embodiment 2

[0055] A preparation method of gold nanoparticles as electron microscope developer, specifically comprising the steps of:

[0056] Dissolve 1g of chloroauric acid in deionized water to prepare a 25mM chloroauric acid solution, and store in the dark at 4°C; dissolve 1.822g of hexadecyltrimethylammonium bromide in 98mL of deionized water to obtain hexadecane Trimethyl ammonium bromide solution (i.e. stabilizer solution), take 2mM of 25mM chloroauric acid solution into cetyl trimethyl ammonium bromide solution, fully stir and mix to obtain a precursor solution, the precursor The mol ratio of cetyltrimethylammonium bromide and chloroauric acid in the body solution is 100:1;

[0057] After dissolving 37.83mg of sodium borohydride in 10mL of deionized water at 0°C, use a pipette gun to take 2mL of it and add it to 98mL of deionized water to obtain a sodium borohydride solution;

[0058] Precursor solution and sodium borohydride solution (the molar ratio of chloroauric acid in the p...

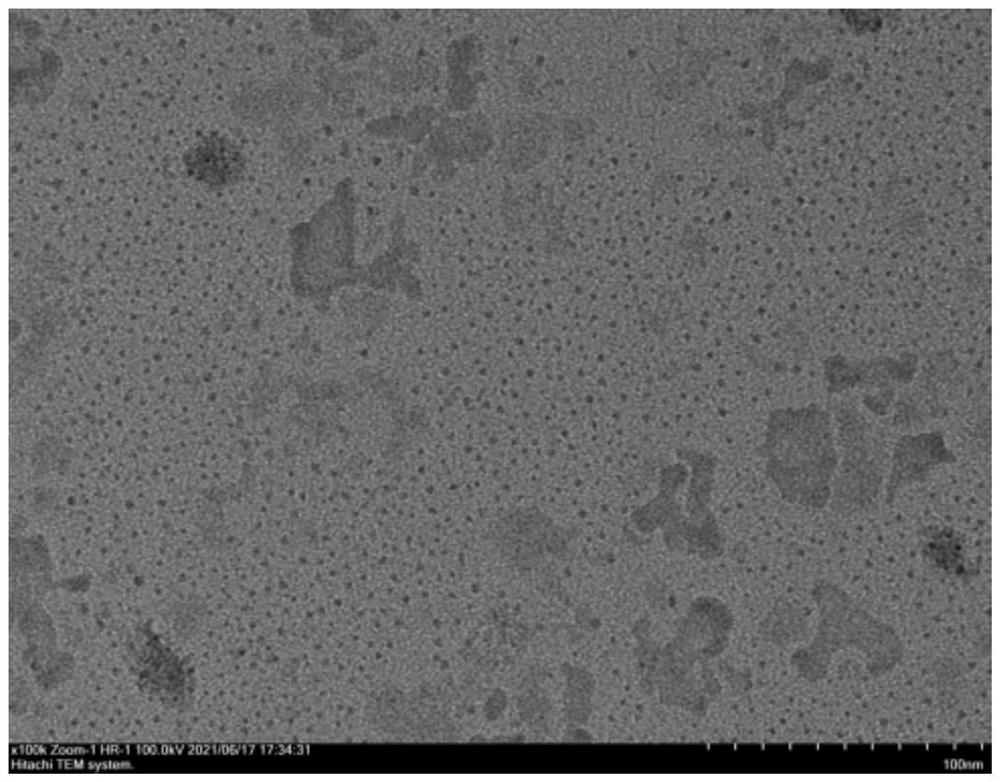

Embodiment 3

[0061] A preparation method of gold nanoparticles as electron microscope developer, specifically comprising the steps of:

[0062] Dissolve 1g of chloroauric acid in deionized water, prepare 25mM chloroauric acid solution, and store in the dark at 4°C; dissolve 1g of hexadecyltrimethylammonium bromide (2.7mmol) in 98mL of deionized water to obtain Cetyltrimethylammonium bromide solution (i.e. stabilizer solution), get the 25mM chloroauric acid solution of 2mL in the cetyltrimethylammonium bromide solution, fully stir and mix to obtain the precursor solution, The mol ratio of cetyltrimethylammonium bromide and chloroauric acid in the precursor solution is 54:1;

[0063] After dissolving 37.83mg of sodium borohydride in 10mL of deionized water at 0°C, use a pipette gun to take 2mL of it and add it to 98mL of deionized water to obtain a sodium borohydride solution;

[0064] Open the supergravity rotating device, adjust the rotor speed to 1000rpm; open the feed pump, adjust the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com