Method for reducing residual stress of base material-additive body interface

A residual stress and base material technology, which is applied in the field of laser powder feeding additive manufacturing, can solve problems such as stress release deformation, base material deformation, and workpiece deformation, and achieve the effects of reducing stress concentration, reducing interface stress, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

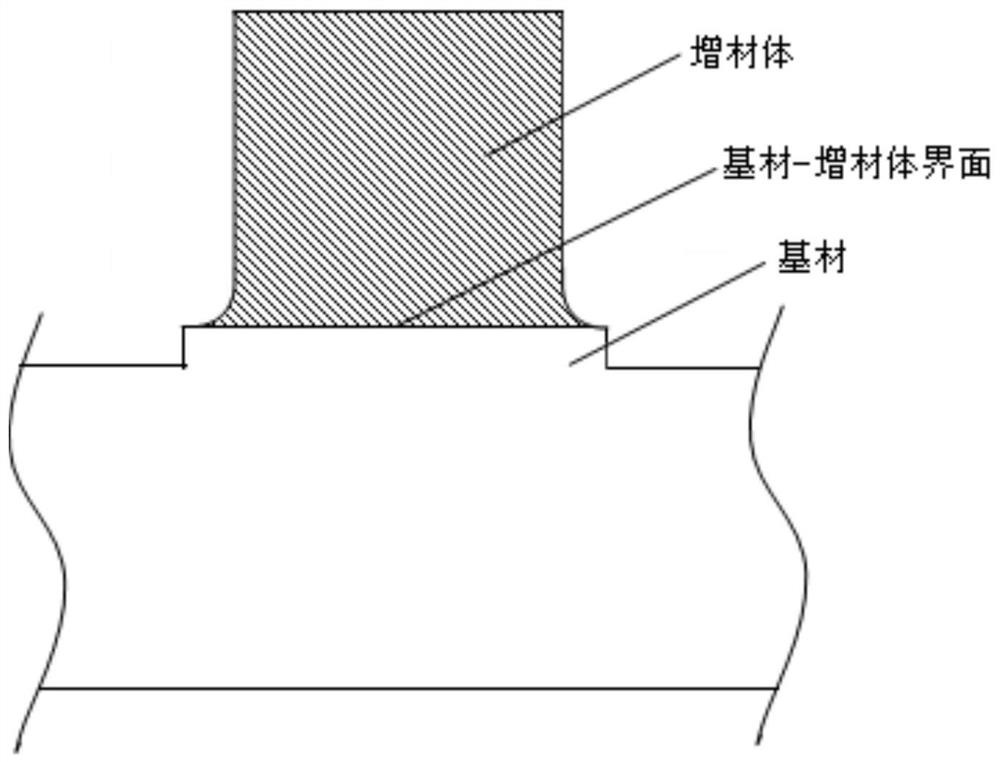

[0035] Such as Figure 1-6 As shown, this embodiment provides a method for reducing the residual stress at the substrate-additive body interface, comprising the following steps:

[0036] Step S1: In the substrate preparation stage, the substrate material around the substrate-additive body interface is removed to form a boss structure on the interface;

[0037] Step S2: Make the additive body grow on the boss structure, and design the transition area between the bottom of the additive body and the base material interface as a rounded transition structure, and then carry out additive manufacturing;

[0038] Step S3: Machining the substrate-additive body component.

[0039] In this embodiment, a surrounding unconstrained boss structure is constructed on the substrate corresponding to the additive manufacturing area, thereby reducing the extrusion and stretching of the surrounding materials during the laser scanning thermal expansion and cooling contraction of the substrate surfa...

Embodiment 2

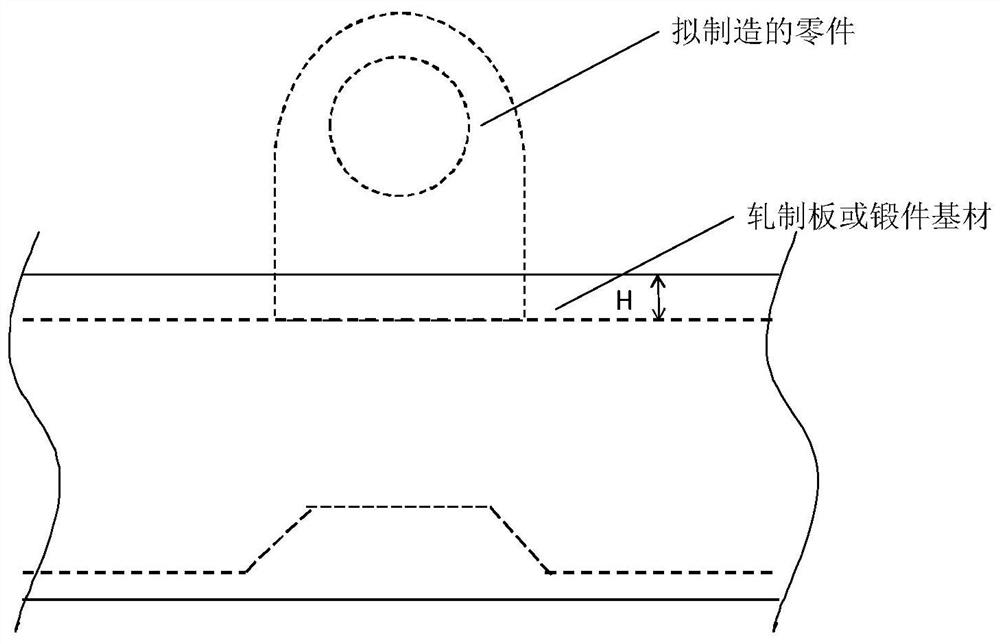

[0058] Such as Figure 1-6 As shown, this embodiment is based on the specific embodiment of embodiment 1, and provides a method for reducing the residual stress at the substrate-additive body interface, including the following steps:

[0059] Step 1: Design the main stress-bearing part of the part in the area of the forging or plate, select the specifications and dimensions of the rolled plate and forging base material according to the main structure of the part, and determine the machining allowance on the base material H = 10mm;

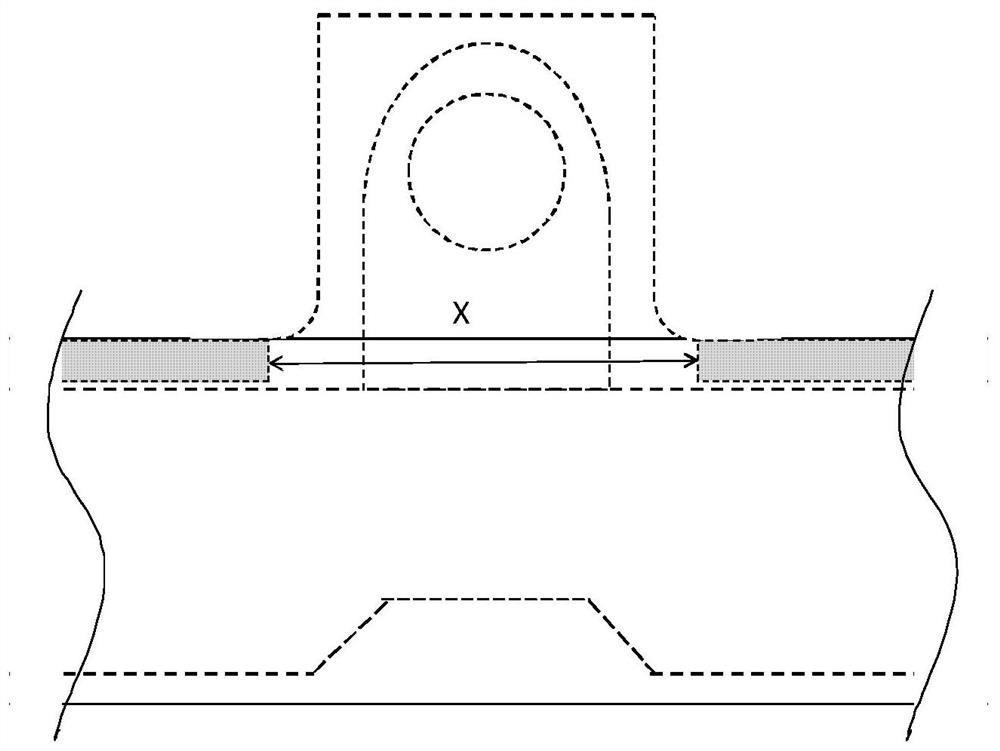

[0060] Step 2: The lugs of the part are processed by the additive body, the width of the ear piece is A=50mm, the machining allowance on the side of the additive body is W=6mm, the transition fillet radius of the substrate-additive body is R=5mm, and the additive body Projection size X=5mm+6mm+50mm+6mm+5mm=72mm;

[0061] Step 3: Outside the range of ±36mm from the center line of the lug, remove the base material with a thickness of h=5mm on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com