Carbon-coated high-nickel positive electrode material, preparation method and application thereof, and lithium ion battery

A positive electrode material and carbon coating technology, which is applied to carbon coated high nickel positive electrode material and its preparation method and application, in the field of lithium ion batteries, can solve the problems of limited rate performance improvement, etc., to improve rate performance and reduce surface by-products The production and preparation method of the simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

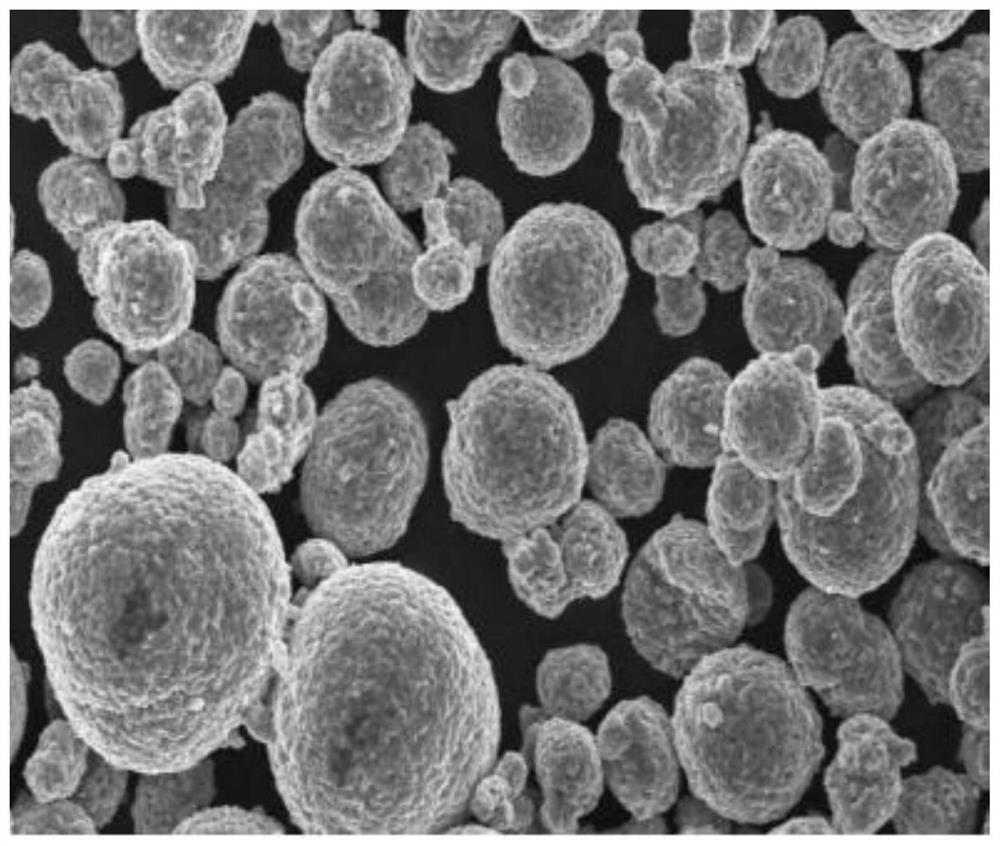

Image

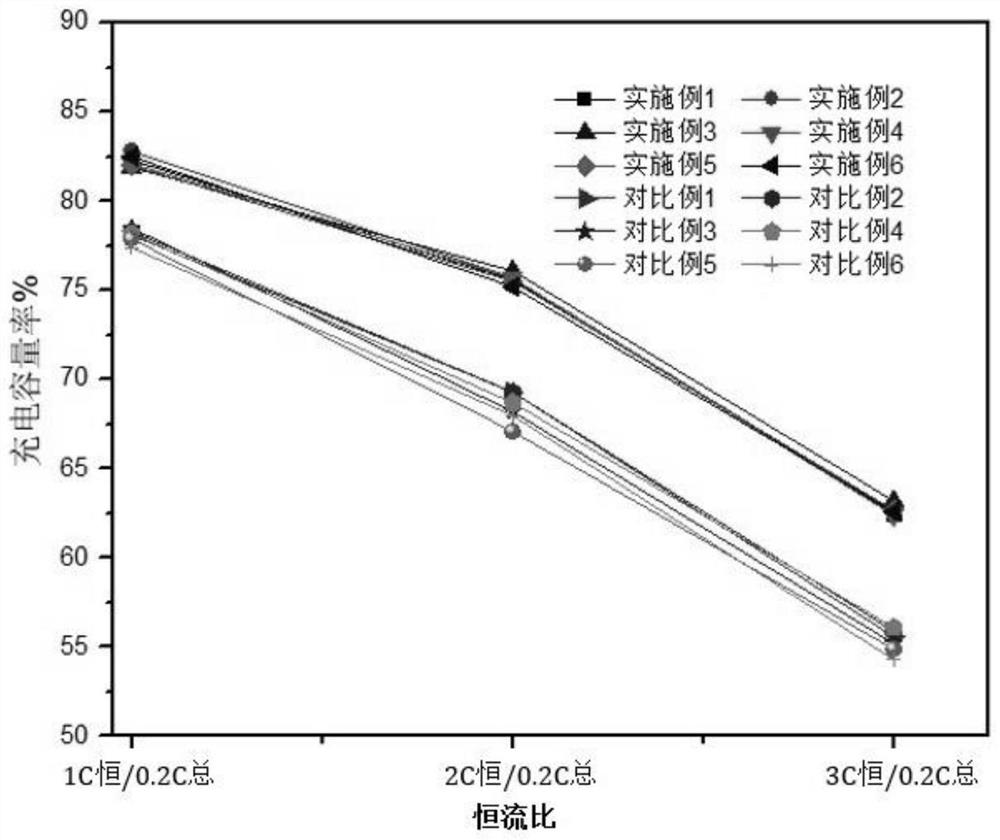

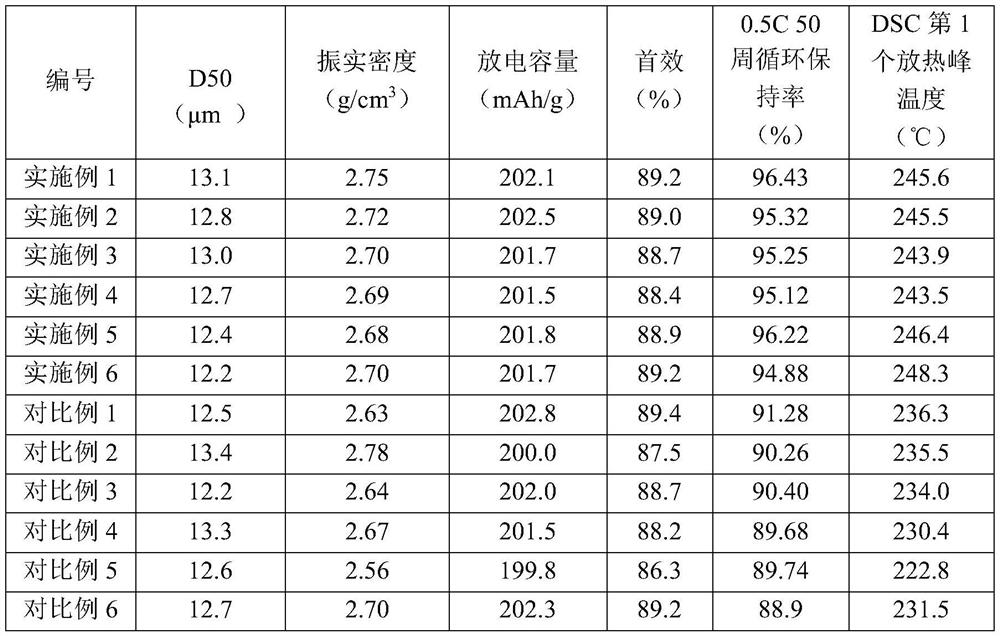

Examples

Embodiment 1

[0075] Petroleum tar residue and graphene slurry are fully dispersed in a 180r / min SGN high-speed German disperser for 40min with a mass ratio of 4:0.02 to obtain a liquid coating agent; battery-grade lithium hydroxide monohydrate (purchased from Ganfeng Lithium Industry Co., Ltd.), Ni 0.88 co 0.05 mn 0.05 al 0.03 o 2 Precursor (purchased from GEM Co., Ltd.), the above-mentioned liquid coating agent with a mass ratio of 102:100:10, was wet coated in a ZSJ-600 fusion machine, no solvent was involved in the coating process, and the wet coating The coating time is 12min, and the rotating speed is 500r / min; among them, the inner wall of the ZSJ-600 fusion machine is equipped with a paddle scraper, and the Ni 0.88 co 0.05 mn 0.05 al 0.03 o 2 The precursor and battery-grade lithium hydroxide monohydrate are mixed and coated in liquid phase, and then subjected to impregnation treatment, adsorption extrusion treatment and rounding treatment to achieve the effect of surface mic...

Embodiment 2

[0079] Embodiment 2 differs from Embodiment 1 in that: petroleum tar residue and graphene slurry are fully dispersed at a mass ratio of 4:0.01, and the others are the same as Embodiment 1. At this time, the median particle size D50 is 12.8μm, and the tap density is 2.72g / cm 3 , PH is 11.7, residual alkali content <0.5%, water content 205ppm, discharge capacity 202.5mAh / g, initial efficiency 89.0%.

Embodiment 3

[0081] The difference between embodiment 3 and embodiment 1 is that petroleum tar residue and graphene slurry are fully dispersed at a mass ratio of 4:0.1, and the others are the same as embodiment 1. At this time, the median particle size D50 is 13.0 μm, and the tap density is 2.70 g / cm 3 , pH is 11.3, residual alkali content is less than 0.5%, moisture is 230ppm, discharge capacity is 201.7mAh / g, and initial efficiency is 88.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap