Digital glaze for ceramic large board or rock board and preparation method of digital glaze

A digital and slate technology, applied in the field of digital glaze for ceramic slabs or slate and its preparation, can solve the problems of difficulty in whiteness and covering power, thin spray glaze surface thickness, poor pattern effect, etc., to save raw materials , The thickness of spray glaze is thin, the effect of spherical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of ceramic slab and rock slab digital glaze of the present invention comprises the following steps:

[0042] S1), the powders of industrial grade feldspar, kaolin, silica fume powder and zirconium dioxide containing potassium and sodium are ball milled respectively, and sieved after the treatment.

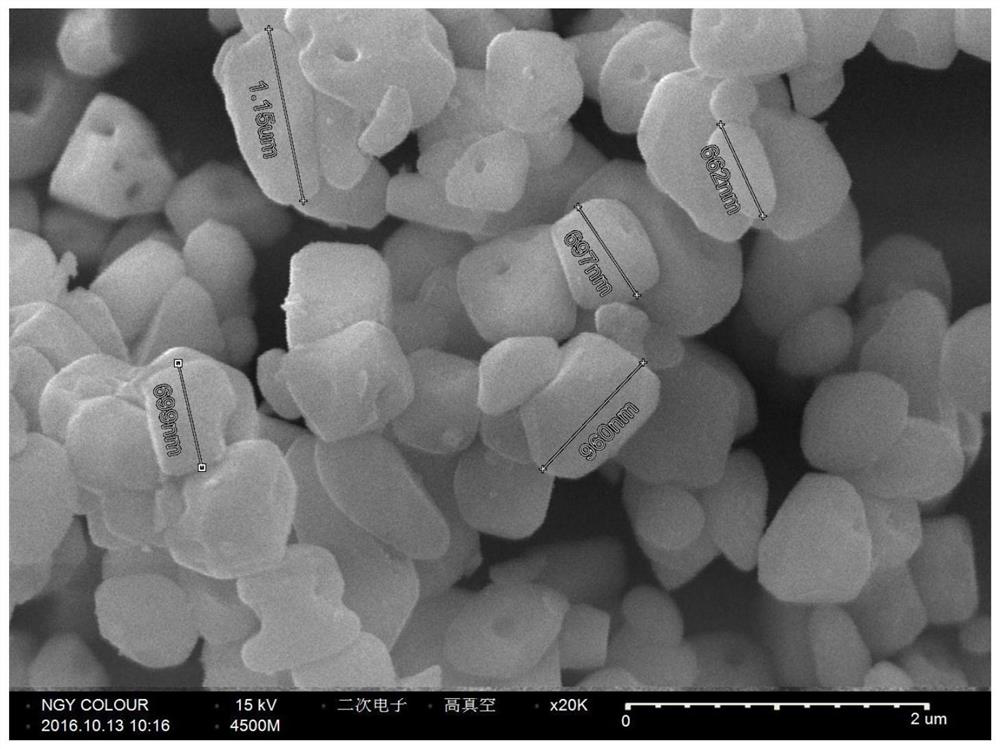

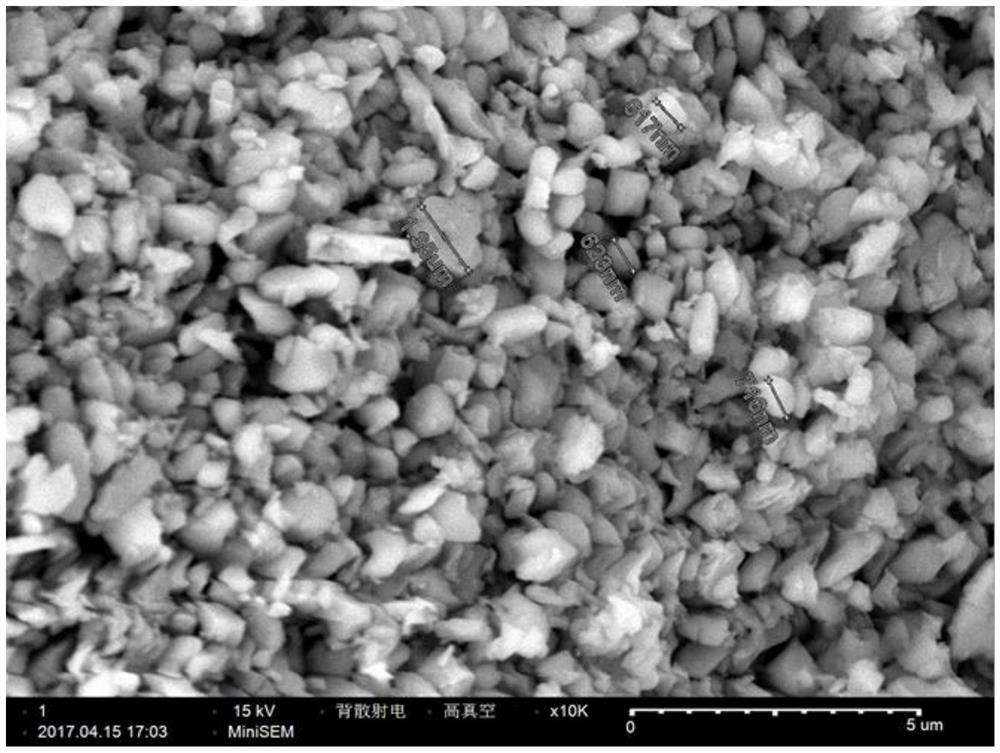

[0043] The time of ball milling is 30-40min; after ball milling, the D50 of each powder is less than 1.5um.

[0044] Each powder after ball milling is passed through a 250-400 mesh sieve.

[0045] S2), the powders sieved in step S1) are dried in an oven at 60-110° C. until the water content of the two samples is less than 0.1%, and the crushing and drying pretreatment powders of the four mineral materials are obtained. .

[0046] S3), the dried powders in step S2) are respectively added to a high mixer for mixing, and then pumped into a sand mill for sand milling to obtain feldspar premix, kaolin premix, and silica fume respectively. powder premix a...

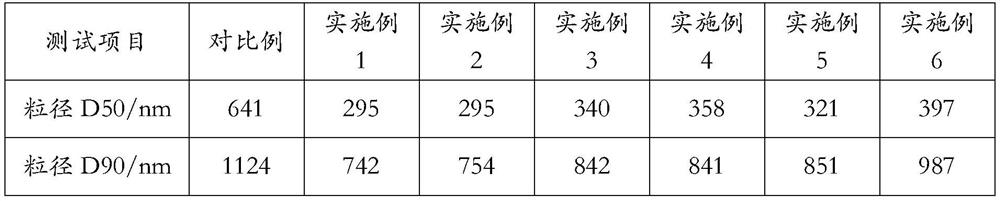

Embodiment 1

[0056] This embodiment is a standard embodiment as a comparison, and the specific composition and preparation method are:

[0057] The special digital glaze for ceramic slabs and rock slabs of the present embodiment comprises, in parts by mass, its raw material components: 15 parts of feldspar (containing potassium, albite), 8 parts of kaolin, 5 parts of silica fume powder, zirconium dioxide 12 parts, 45 parts of solvent, 8 parts of dispersant, 7 parts of co-solvent.

[0058] The specific preparation method of the special digital glaze for ceramic slabs and rock slabs of this embodiment is as follows:

[0059] S1), the powders of industrial grade feldspar, kaolin, silica fume powder and zirconium dioxide containing potassium and sodium are ball milled respectively, and sieved after the treatment.

[0060] The time for ball milling is 30 minutes; after ball milling, the D50 of each powder is less than 1.5um.

[0061] Each powder after ball milling is passed through a 400-mesh...

Embodiment 2

[0069] This example is an example in which no co-solvent is added and the solvent content is increased accordingly. In the components of this example, the content of zirconia is reduced and the content of feldspar is correspondingly increased. Concrete composition and preparation method are:

[0070] The special digital glaze for ceramic slabs and rock slabs of the present embodiment includes its raw material components in parts by mass: 24 parts of feldspar (containing potassium, albite), 8 parts of kaolin, 5 parts of silica fume powder, zirconium dioxide 3 parts, 52 parts of solvent, 8 parts of dispersant, 0 parts of co-solvent.

[0071] The specific preparation method of the special digital glaze for ceramic slabs and rock slabs of this embodiment is as follows:

[0072] S1), the powders of industrial grade feldspar, kaolin, silica fume powder and zirconium dioxide containing potassium and sodium are ball milled respectively, and sieved after the treatment.

[0073] The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com