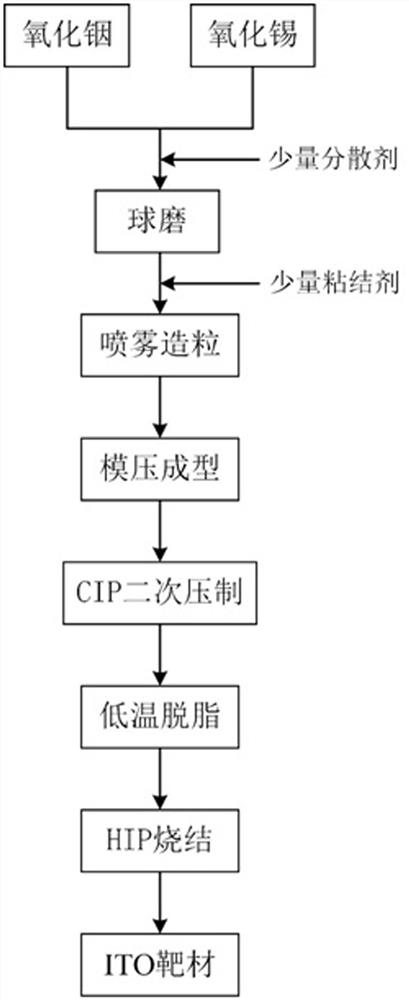

Preparation method of ITO ceramic target material

A ceramic target, wet ball milling technology, applied in ceramic molding machines, manufacturing tools, metal material coating processes, etc., can solve the problems of long production cycle, low production efficiency, etc. The effect of shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh In 2 o 3 : SnO 2 The raw material powder with a mass ratio of 90:10 is mixed with pure water, polyacrylic acid dispersant, and binder by ball milling as required to prepare an ITO slurry with a solid content of 50%;

[0040] Spray granulation of ITO slurry to obtain average particle size D 50 It is 10 μm spherical granulated powder;

[0041] Put the ITO granulation powder into a special mold for molding, the molding pressure is 60 MPa, and the holding time is 5 minutes to obtain an ITO green body with a density of 38%.

[0042] The ITO green body was formed by cold isostatic pressing with a holding pressure of 200 MPa and a holding time of 30 minutes to obtain an ITO green body with a density of 60%.

[0043] Degreasing 10h under the condition of ITO green body temperature 800 °C;

[0044] The degreased ITO biscuit is put into a low-carbon steel ladle, and 304 stainless steel insulation material is added between the sheath and the ITO biscuit, and hot isostat...

Embodiment 2

[0047] Weigh In 2 o 3 : SnO 2 The raw material powder with a mass ratio of 90:10 is mixed with pure water, polyacrylic acid dispersant, and binder by ball milling as required to prepare an ITO slurry with a solid content of 50%;

[0048] Spray granulation of ITO slurry to obtain average particle size D 50 It is 10 μm spherical granulated powder;

[0049] Put the ITO granulation powder into a special mold for molding, the molding pressure is 60 MPa, and the holding time is 5 minutes to obtain an ITO green body with a density of 38%.

[0050] The ITO green body was formed by cold isostatic pressing with a holding pressure of 200 MPa and a holding time of 30 minutes to obtain an ITO green body with a density of 60%.

[0051] Degreasing 10h under the condition of ITO green body temperature 800 ° C;

[0052] The degreased ITO biscuit is put into a low-carbon steel ladle, and 304 stainless steel insulation material is added between the sheath and the ITO biscuit, and hot isosta...

Embodiment 3

[0055] Weigh In 2 o 3 : SnO 2 The raw material powder with a mass ratio of 90:10 is mixed with pure water, polyacrylic acid dispersant, and binder by ball milling as required to prepare an ITO slurry with a solid content of 50%;

[0056] Spray granulation of ITO slurry to obtain average particle size D 50 It is 10 μm spherical granulated powder;

[0057] Put the ITO granulation powder into a special mold for molding, the molding pressure is 60 MPa, and the holding time is 5 minutes to obtain an ITO green body with a density of 38%.

[0058] The ITO green body was formed by cold isostatic pressing with a holding pressure of 200 MPa and a holding time of 30 minutes to obtain an ITO green body with a density of 60%.

[0059] Degreasing 10h under the condition of ITO green body temperature 800 ° C;

[0060] The degreased ITO biscuit is put into a low-carbon steel ladle, and 304 stainless steel insulation material is added between the sheath and the ITO biscuit, and hot isosta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com