A method for separating cholesterol and 24-dehydrocholesterol by complex crystallization

A technology for separation of dehydrocholesterol and crystallization, which is applied in the fields of steroids and organic chemistry, can solve the problems of long production cycle, cumbersome process, low selectivity and extraction capacity, and achieve low production equipment requirements, simple operation process, good separation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

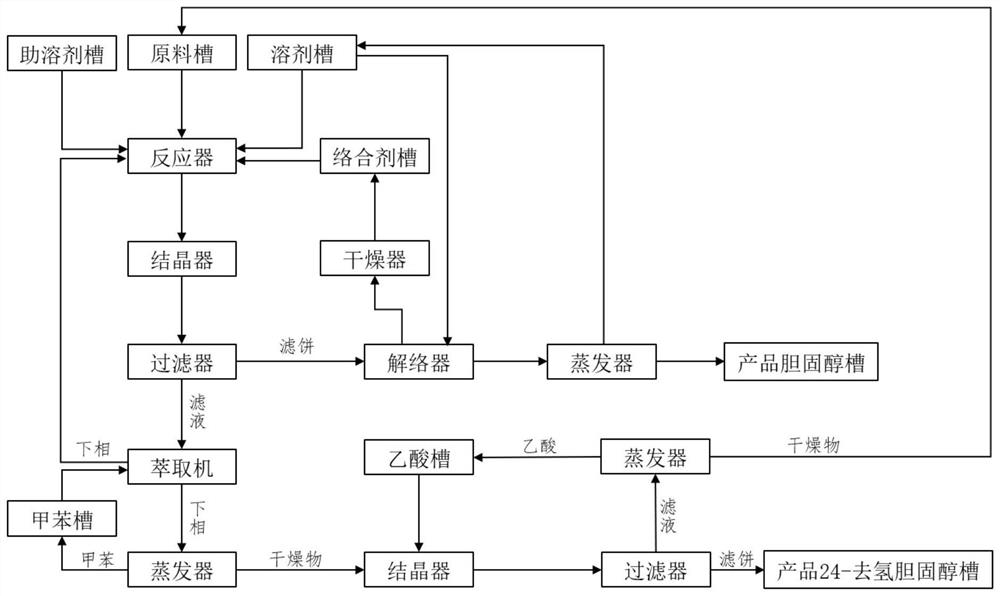

Method used

Image

Examples

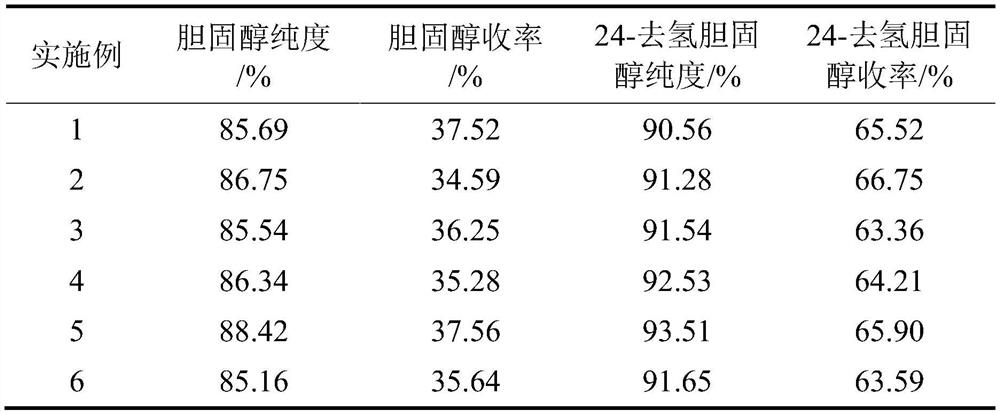

Embodiment 1

[0037] 1) Complex crystallization: cholesterol and 24-dehydrogen cholesterol mixed raw materials (cholesterol: 24-dehydrogen cholesterol = 8: 9), methanol, CuCl, concentrated hydrochloric acid (36%) according to the mass ratio of 1: 17: 0.5: 1.6 prepared as a mixed solution, with nitrogen to replace the air in the reactor after stirring at 30 °C protected from light for 1h. After the end of the reaction, the cooling crystallization is carried out, the cooling speed is 5 °C / h, the crystallization temperature is -10 °C, and the crystallization time is 5h.

[0038] 2) Filtration washing: the reaction liquid is filtered to obtain the filtrate and the filter cake, and the filter cake is washed and filtered 3 times using -10 °C methanol, and the methanol quality used for each wash is 2 times the quality of the filter cake.

[0039] 3) Filter cake decombination: Remove the filter cake from step 2) and dissolve it at 30 °C with methanol 17 times the mass of the filter cake. The complexing...

Embodiment 2

[0044] The experimental apparatus and the operating process are the same as Example 1, only step 1), the complexing agent CuCl is replaced by copper tetrafluoroborate, and the analysis results are shown in Table 1.

Embodiment 3

[0046] The experimental apparatus and the operating process are the same as Example 1, only step 1), the solvent methanol is replaced by isopropanol, the mass ratio of raw materials to solvents is changed to 1:11, the crystallization temperature is -20 ° C, and the crystallization time is 10h; Step 2) in which the detergent is replaced by isopropanol at -20 °C; Step 3) In step 3), the solvent is replaced with isopropanol 11 times the mass of the filter cake, and the analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com