Degradable PBAT composite film and preparation method thereof

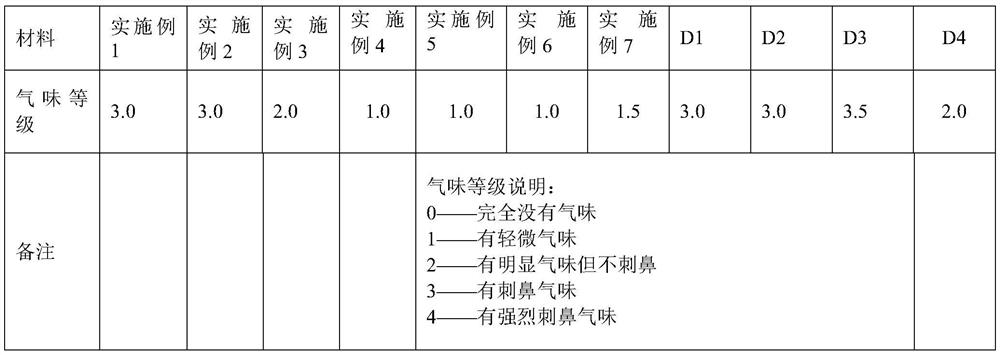

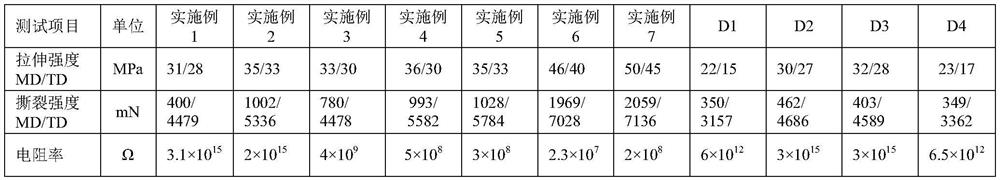

A composite film and ring-opening polymerization technology, which is applied in the field of low-odor biodegradable PBAT composite film and its preparation, can solve the problems of film bags with strong odor, affecting development and application, and poor user experience, achieving better smell, Odor reduction and odor improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Preparation of Metal Organic Framework (MOF)

[0056] Weigh 100g of zirconium chloride and 100g of 2-aminoterephthalic acid into the flask, add 300mL of N'N dimethylformamide, then add 40mL of deionized water, stir well and transfer to a flask equipped with a polytetrafluoroethylene liner In a high-pressure reactor, react at 150°C for 36h. After the reaction kettle was naturally cooled, 300 mL of N’N dimethylformamide was added to the product, ultrasonically washed for 10 minutes, transferred to a rotary evaporator, and evaporated to dryness at 80°C. The obtained yellow powder was washed three times with methanol in a suction filtration device, and then dried in an oven at 100°C.

[0057] (2) Preparation of modified metal-organic framework (M-MOF)

[0058] Weigh 100g of metal-organic framework prepared in step (1) and 150g of KH-560 into a three-necked flask, add 300mL of N’N dimethylformamide, stir well, and react in an oil bath at 150°C for 8h. After natural co...

Embodiment 2

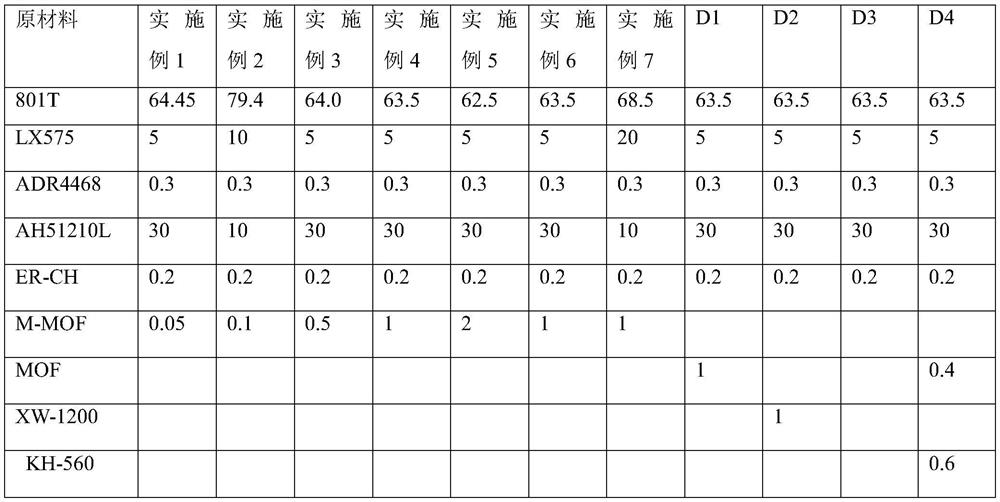

[0066] The modified metal-organic framework (M-MOF) prepared in Example 1 was used as the raw material, and the PBAT composite film was prepared according to the method in Example 1. The difference was that the proportion of the modified metal framework added was different. For the specific formula, refer to Table 1.

Embodiment 3

[0068] The modified metal-organic framework (M-MOF) prepared in Example 1 was used as the raw material, and the PBAT composite film was prepared according to the method in Example 1. The difference was that the proportion of the modified metal framework added was different. For the specific formula, refer to Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com