Negative liquid crystal composition and application

A technology of negative liquid crystals and compositions, applied in liquid crystal materials, nonlinear optics, optics, etc., can solve the problems of high driving voltage and slow response time of negative liquid crystals, and achieve the effect of improving contrast and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

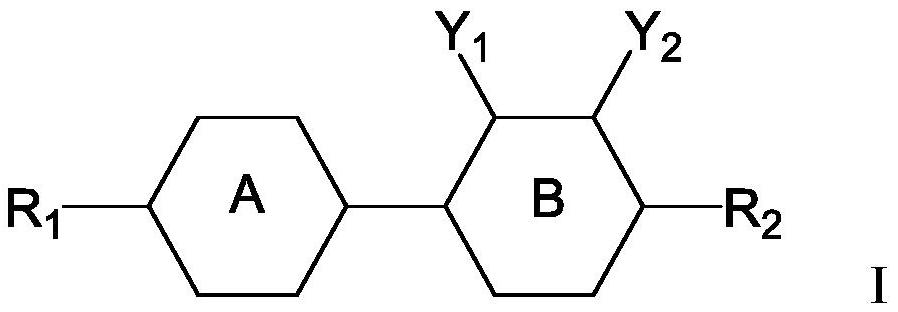

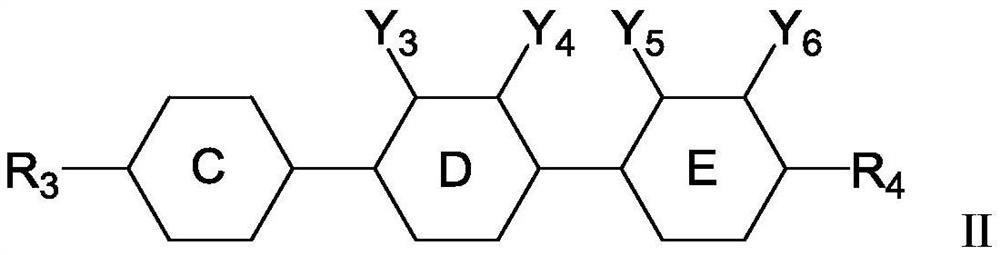

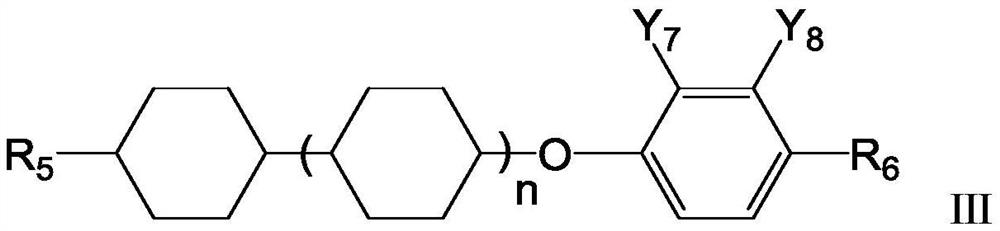

Method used

Image

Examples

preparation example Construction

[0059] The preparation of the liquid crystal composition of the present invention adopts the following method: weigh the compounds according to the proportions in any one of the examples, and place them in a hard high borosilicate glass bottle for mutual miscibility. Heat the mixture according to the principle of clearing point + 20°C, and stir it with electromagnetic or mechanical stirring until it becomes a molten, clear and homogeneous transparent solution, and then continue to stir for 30 minutes to make the materials thoroughly and evenly mixed, then stop heating. Under reduced pressure and degassing under stirring; as the temperature decreases, the degree of vacuum increases until the temperature cools to room temperature, then stop stirring and continue to evacuate until no bubbles appear.

[0060] Under the protection of nitrogen, use a sand core funnel to filter the mixed liquid crystal into a clean and dry hard high borosilicate suction filter bottle; In the desiccat...

Embodiment 1

[0072] According to the proportions of the components of the liquid crystal composition shown in Table 1, the liquid crystal composition was prepared according to the method described in the present invention, and poured into a test box for performance testing. The measured performance parameters are shown in Table 1.

[0073] Table 1 The proportioning and performance parameters of the liquid crystal composition of Example 1

[0074]

Embodiment 2

[0076] According to the proportions of the components of the liquid crystal composition shown in Table 2, the liquid crystal composition was prepared according to the method described in the present invention, and poured into a test box for performance testing. The measured performance parameters are shown in Table 2.

[0077] Table 2 The proportioning and performance parameters of the liquid crystal composition of Example 2

[0078]

[0079]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com