Oil-rich coal underground pyrolysis heat energy recycling system

An underground heat and thermal energy technology, applied in underground mining, coal gasification, energy input, etc., can solve the problem of large heat consumption, and achieve the effect of reducing carbon emissions, reducing emissions, and improving energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

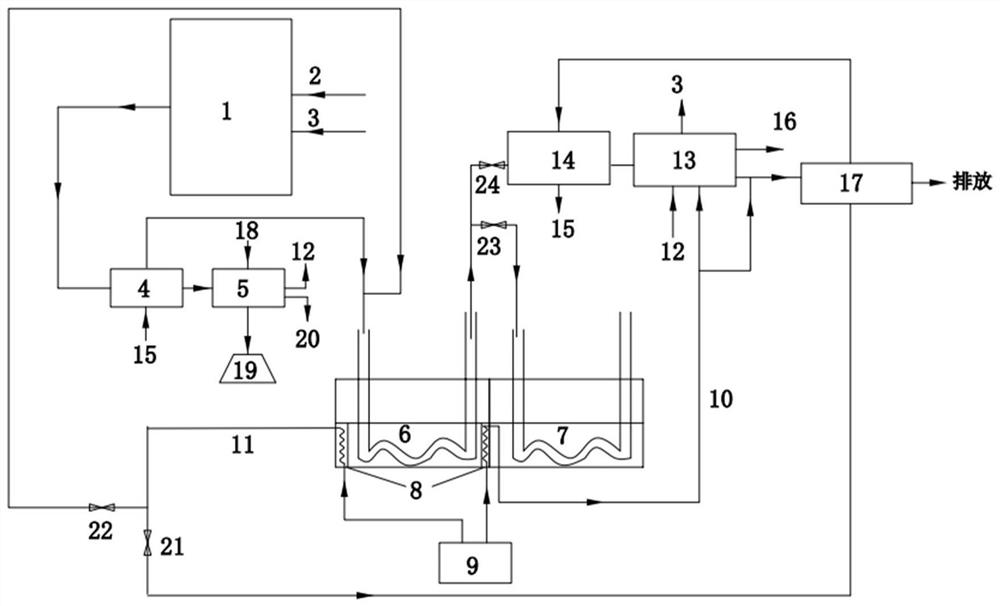

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

[0024] see figure 1 , an oil-rich coal underground pyrolysis thermal energy recycling system provided by the present invention, comprising a combustion chamber 1, a fuel 2, a combustion-supporting gas 3, a high-temperature heat exchanger 4, a waste heat boiler 5, a No. 1 coal seam block 6, and a No. 2 coal seam Block 7, freeze wall 8, air separation unit 9, pure oxygen 10, pure nitrogen 11, circulating carbon dioxide 12, gas-liquid separator 13, waste heat exchanger 14, pure nitrogen heated by waste heat exchanger 15, oil product 16. Chemical Loop Oxidation 17, Organic Cycle Working Fluid 18, Expander 19, CO 2 Capture process 20 , first valve 21 , second valve 22 , third valve 23 , and fourth valve 24 . The system comprehensively considers the in-situ pyrolysis part of oil-rich coal and the waste heat utilization part, combines chemical looping oxidation technology a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com