Method and device for nondestructive testing of crystal orientation difference and grain boundary defects in single crystal or oriented crystal

A technology of crystal orientation and directional crystallization, which is applied in measuring devices, material analysis using radiation diffraction, instruments, etc., can solve the problems of long time consumption and no existing literature disclosure, etc., and achieve the effect of reliable crystal orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

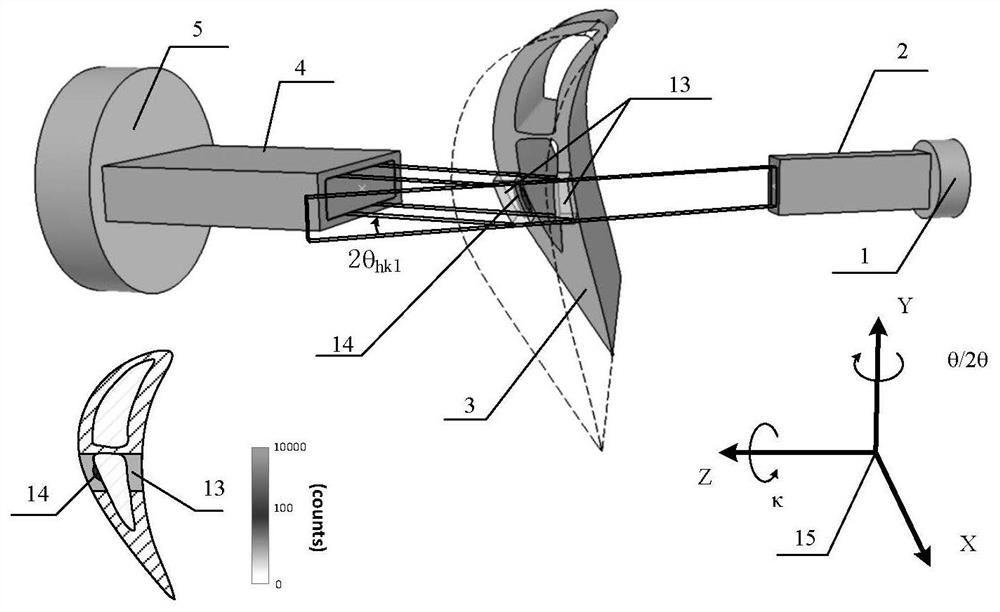

[0085] Example method for detecting the focus of this embodiment describes a single crystal inside a crystal orientation difference and the grain boundary defects lossless, in particular non-destructive testing internal γ crystal nickel-base superalloy blades' phase (200) plane orientation difference and the grain boundary defect.

[0086] In this embodiment diffractometer using a tungsten target X-ray tube, a tungsten target X-ray tube focal spot size of 5.5mm × 5.5mm, the selected diffraction WKα 1 Having a wavelength of 0.0209nm, the corresponding photon energy 59.3kev.

[0087] Wherein diffractometer:

[0088] The X-ray detection system is a single point detection system, and its energy resolution is superior to 2%;

[0089] The incident exclusion and receiving collimator are prepared by tungsten alloy material, the incident alignor and the receiving column light hole are rectangular light holes, and the height of the light hole and the shaft of θ and 2θ are parallel, and the l...

Embodiment 2

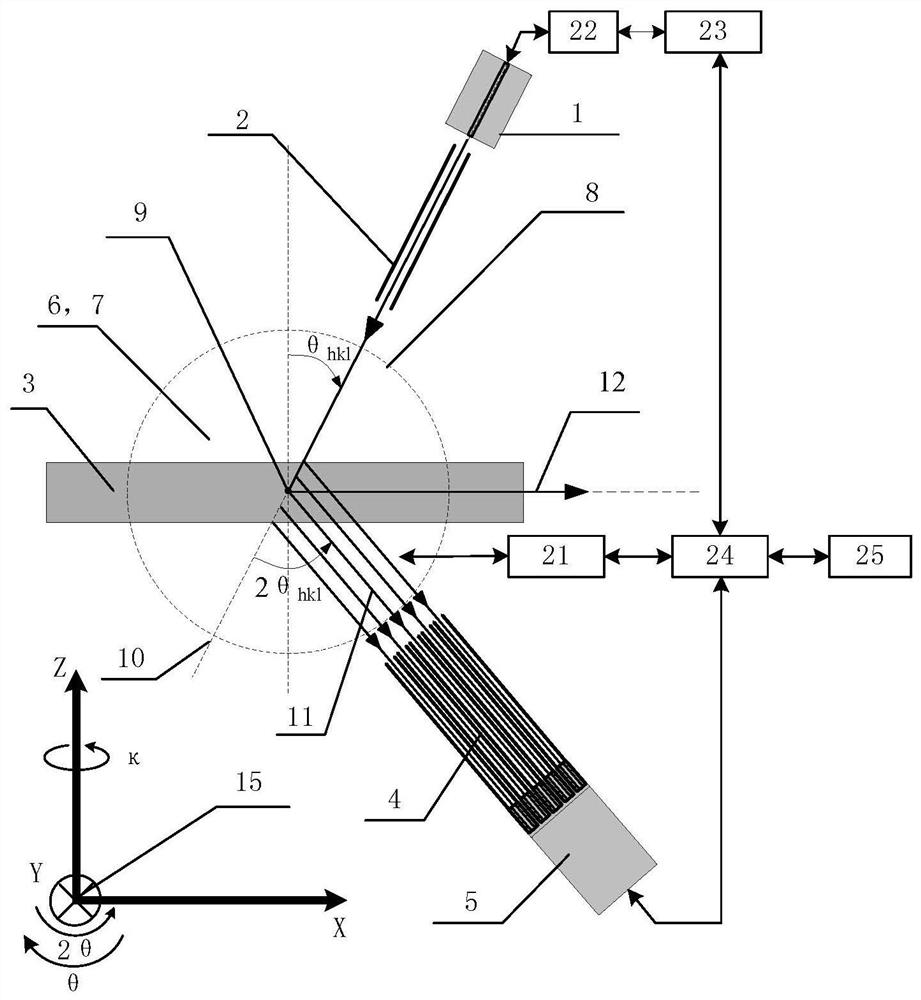

[0105] The present embodiment focuses on non-destructive detection directional crystals internal crystal orientation differences and grain boundary defects, specifically non-destructive detection of nickel-based high-temperature alloy directional crystal parts internal γ 'phase (200) crystal surface orientation difference and grain boundary defect.

[0106] In the present embodiment, the diffraction device is used with a tungsten target X-ray tube, and the tungsten target X-ray tube focus size is 0.4 mm × 0.4 mm, and WKα for diffraction is selected. 1 It has a wavelength of 0.0209 nm, and its corresponding photon energy is 59.3kev.

[0107] Among them, the diffractive device:

[0108] The X-ray detection system is an array detection system that includes a one-dimensional receiving array crimp and a two-dimensional array detector;

[0109] The inclusion and one-dimensional reception array crimp are prepared by heavy metals such as tungsten alloys and their alloy materials. The two-...

Embodiment 3

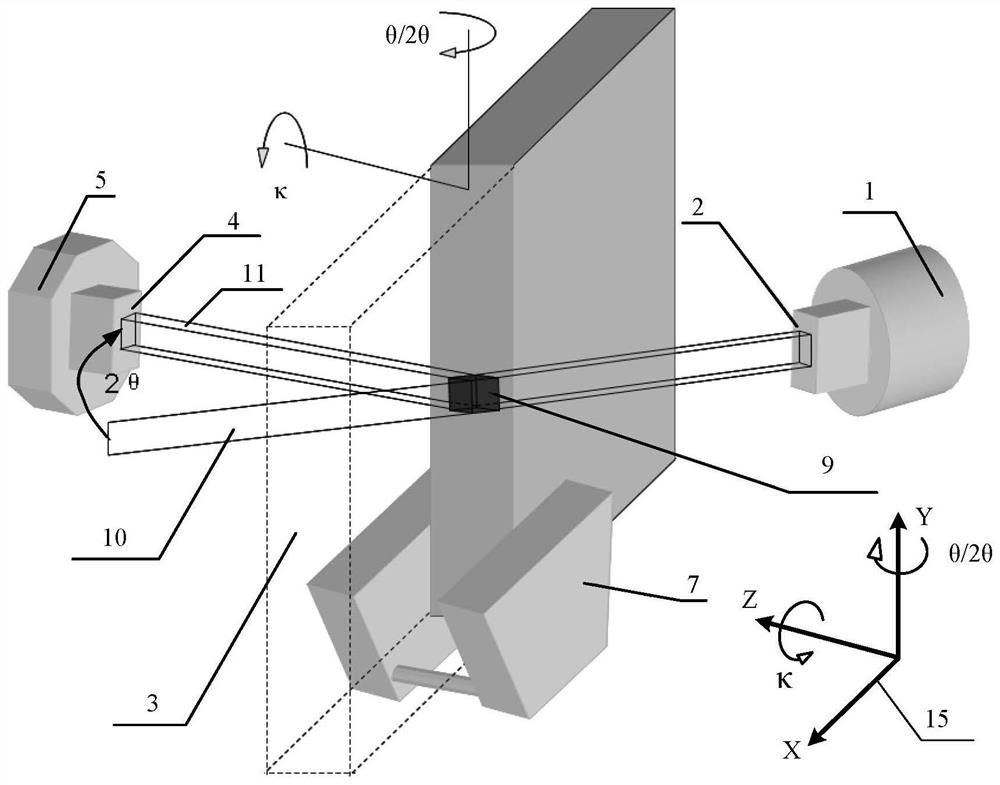

[0125] This embodiment focuses on non-destructive detection of hollow single crystal internal crystal orientation differences and grain boundle defects, specifically non-destructive detection of the internal γ 'phase (420) crystal surface orientation difference between the nickel-based high-temperature alloy hollow single crystal cross section and the grain boundary defect.

[0126] The method and apparatus employed in this example refer to Example 2, which is the main difference from Example 2 in:

[0127] The sample was measured as a nickel-based high-temperature alloy hollow single crystal sample;

[0128] Added a diffraction intensity correction method;

[0129] Each parameter is different: the present embodiment uses the gold target X-ray tube as a radiation source, its focus size is 5.5mm × 5.5mm, and the diffraction is used for Aukα 1 The wavelength is 0.0180 nm, and its corresponding photon energy is 68.794 Kev, γ '- (420) diffraction angle 2θ of the crystal plane 420 = 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com