Deep ultraviolet LED epitaxial structure and preparation method thereof

An epitaxial structure, deep ultraviolet technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor crystal quality and high dislocation density of AlGaN materials, improve crystal quality, reduce threading dislocations, and improve optoelectronic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The embodiment of the present invention provides an epitaxial structure and preparation method applied to deep ultraviolet light-emitting diodes. For the specific preparation steps, refer to Comparative Example 1. The difference is that the following steps are added after step S2 and between step S3: A flat substrate 1 with an AlN buffer layer 2 is put into a physical vapor deposition device, namely a PVD device, for plasma pretreatment, and nitrogen and oxygen are fed alternately in a pulsed manner. The input amount is 5sccm, the time is 5s, one cycle of nitrogen and oxygen is one cycle, and the number of pulse cycles is 10. The power of the alternating electric field applied to the chamber is 50W, the process temperature is 450°C, and the pressure is 4mTorr”;

[0043] Finally, a deep ultraviolet LED epitaxial structure 1 is produced.

Embodiment 2

[0045] The embodiment of the present invention provides an epitaxial structure and preparation method applied to deep ultraviolet light-emitting diodes. For the specific preparation steps, refer to Comparative Example 1. The difference is that the following steps are added after step S2 and between step S3: A flat substrate 1 with an AlN buffer layer 2 is placed into a physical vapor deposition device, namely a PVD device, for plasma pretreatment, and nitrogen and oxygen are introduced at the same time. The power of the alternating electric field applied to the cavity is 60W, the process temperature is 450°C, and the pressure is 4.5mTorr”;

[0046] Finally, a deep ultraviolet LED epitaxial structure 2 is produced.

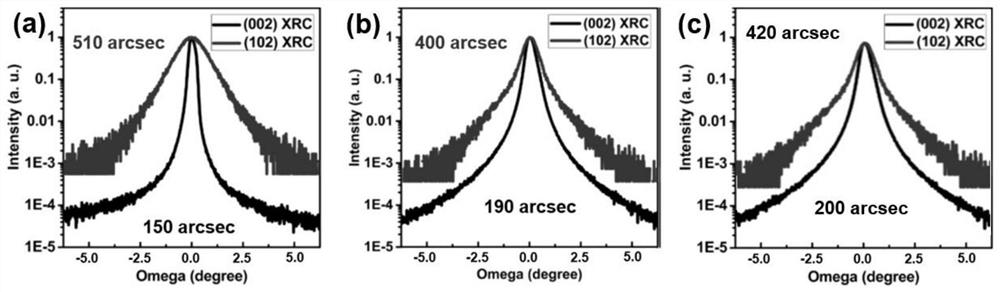

[0047] The deep ultraviolet LED epitaxial structures prepared in Comparative Example 1 and Examples 1 and 2 were respectively subjected to XRD:002 twin crystal diffraction analysis and XRD:102 twin crystal diffraction analysis, the analysis diagram is as follows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com