Method for preparing indium arsenide/indium phosphide quantum dot laser epitaxial wafer with ultra-wide light emission spectrum

A technology of quantum dots and indium arsenide, which is applied in the field of preparing laser epitaxial wafers and indium arsenide/indium phosphide quantum dot laser epitaxial wafers with ultra-wide emission spectrum, which can solve the problem that the size distribution of quantum dots is difficult to control and the energy level is extremely high. Uniform broadening, unfavorable gain and other problems, to achieve the effect of wide applicability, simple steps, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

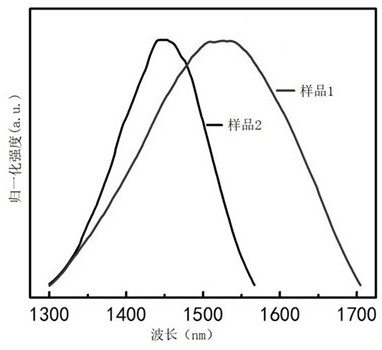

[0027] Example: Sample 1

[0028] A method for preparing an indium arsenide / indium phosphide quantum dot laser epitaxial wafer with an ultra-broad emission spectrum, comprising the steps of:

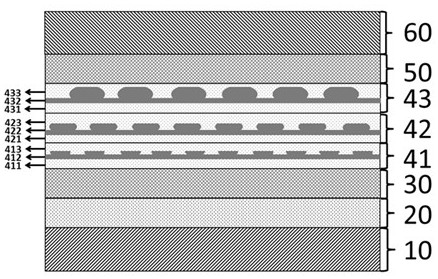

[0029] Step 1: Select the substrate 10, which is n + type indium phosphide single wafer, the crystal orientation is (100), its doping element is Si, and the doping concentration is (1-3)×10 18 cm -3 .

[0030] Step 2: epitaxially grow a layer of indium phosphide buffer layer 20 on the indium phosphide substrate, the growth thickness of the indium phosphide buffer layer is 500nm, perform n-type doping on it, the doping element is Si element, doping The concentration is 1×10 18 cm -3 .

[0031] Step 3: Epitaxially grow InGaAsP lower confinement layers 30 on the InP buffer layer 20 with a growth thickness of 200 nm, which is an intrinsic material without doping.

[0032] Step 4: By controlling the deposition thickness of quantum dots and the thickness of the first capping layer, sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Growth thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com