Instant coarse cereal porridge and preparation method thereof

A technology for instant porridge and miscellaneous grain porridge, which is applied in the food field, can solve the problems of inability to show physiological functional characteristics, poor taste of corn ballast, poor processing characteristics, etc., and achieves great development prospects, increases the content of plant polysaccharides, and reduces the effect of concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention provides the preparation method of above-mentioned multigrain instant porridge, comprising the following steps:

[0025] (1) white granulated sugar, stabilizer and water are mixed to obtain a colloid mixed solution;

[0026] (2) After mixing the colloid mixed solution with the corn, mung bean, red kidney bean, peanut, glutinous rice and medlar; sterilizing the mixed raw materials to obtain miscellaneous grain instant porridge; the colloid mixed solution and miscellaneous grain instant porridge The mass volume ratio is 20~28g:1000ml.

[0027] The present invention mixes white granulated sugar, a stabilizer and water to obtain a colloid mixed solution. In the present invention, the mixing method is preferably to add the white granulated sugar and part of the water, and then add the stabilizer; when the white granulated sugar and the stabilizer are all dissolved, add the remaining water. In the present invention, the mixing is preferably accompanied...

Embodiment 1

[0034] 1. Weigh miscellaneous grains (42.3g of corn crumbs, 5.8g of mung beans, 13.4g of red kidney beans, 11.6g of peanuts, 13.1g of glutinous rice and 4.4g of medlar), and wash them continuously for 3 times;

[0035] 2. Take 6.16g of white granulated sugar, which is 6.8% of the total mass of miscellaneous grains (corn slag, mung beans, red kidney beans, peanuts, glutinous rice and medlar); weigh 0.875g of xanthan gum, which is the final system of miscellaneous grains instant porridge (250mL ) of 0.35%; 0.0375g of disodium edetate, which is 0.15‰ of the final system of multigrain instant porridge (250mL); 0.75g of sodium citrate, which is 0.3% of the final system of multigrain instant porridge (250mL); Sodium polyphosphate 0.0875g is 0.35‰ of the final system of multigrain instant porridge (250mL), D-sodium erythorbate 2.5g is 1% of the final system of multigrain instant porridge (250mL); In a large beaker of warm water, then add xanthan gum, disodium edetate, sodium citrate,...

Embodiment 2

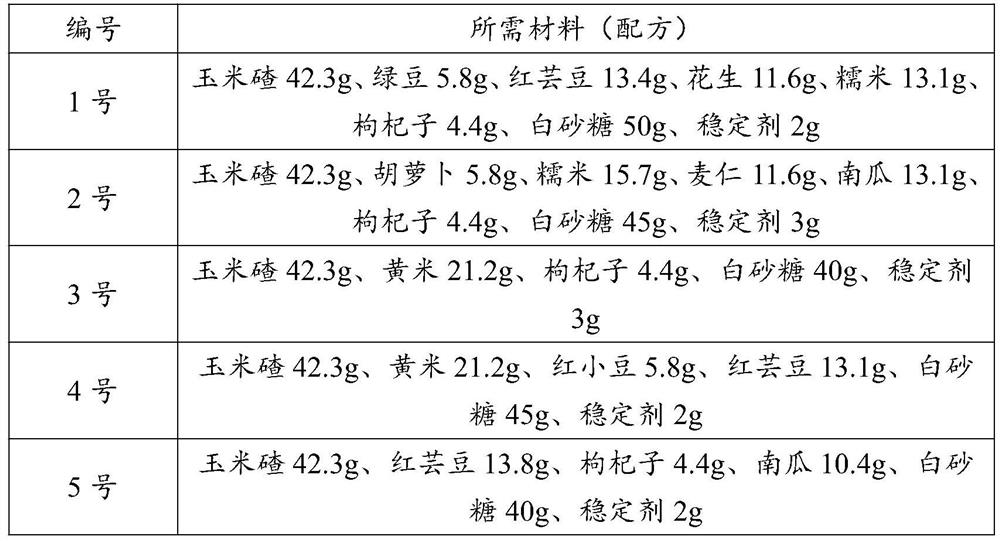

[0039] Different raw materials are used to make multigrain instant porridge, and the dosage of specific raw materials is shown in Table 1.

[0040] Table 1 The amount of raw materials of different miscellaneous grain instant porridge

[0041]

[0042] The preparation method is the same as in Example 1.

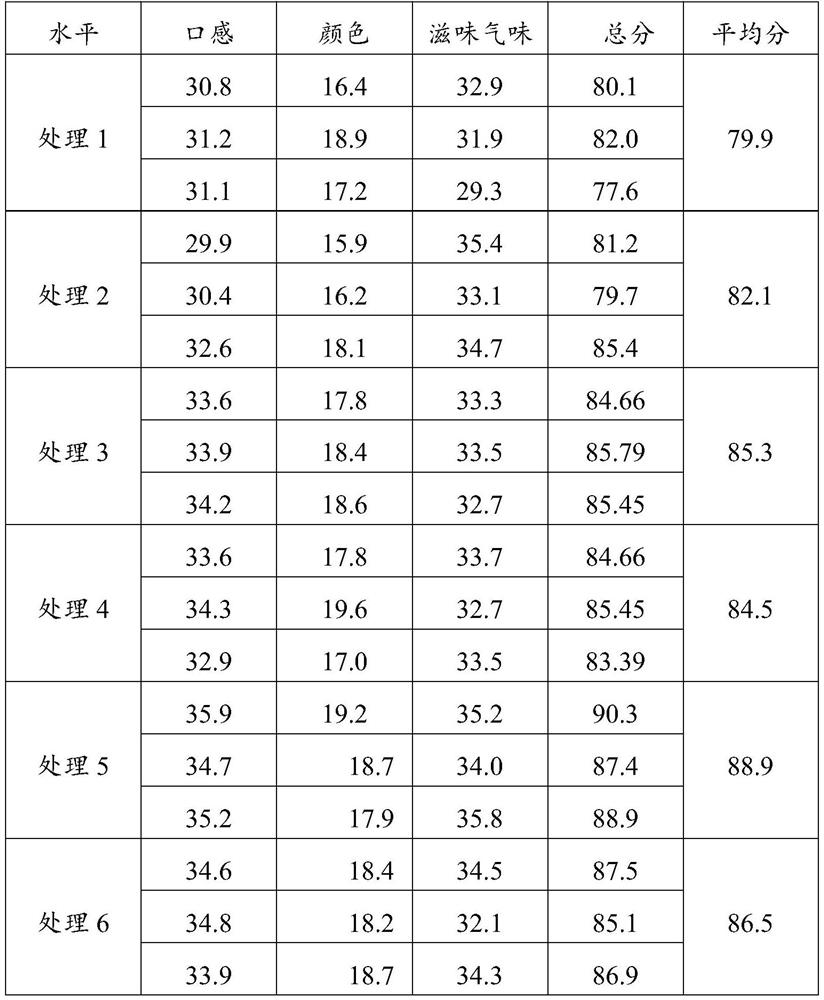

[0043] The multigrain instant porridge prepared from No. 1 to No. 5 was investigated, and the survey criteria were color (0-20 points), taste (0-20 points), taste and smell (0-20 points), and organizational state (0-20 points). points) and aftertaste (0-20 points), the full score is 100 points, the higher the score, the more qualified; the investigators are composed of teachers, postgraduates and undergraduates majoring in food, including 5 teachers, 10 postgraduates, and 15 undergraduates ; The survey results are shown in Table 2.

[0044] Table 2 Survey results

[0045] serial number color smell taste smell organizational status Aftertaste total sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com