Sulfur-resistant monodisperse fusiform monatomic catalyst for denitration and preparation method of sulfur-resistant monodisperse fusiform monatomic catalyst

A monodisperse, catalyst technology, used in separation methods, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of increasing the active site of the reaction, fast reaction, efficient denitration and anti-sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

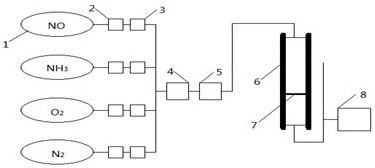

Method used

Image

Examples

Embodiment 1

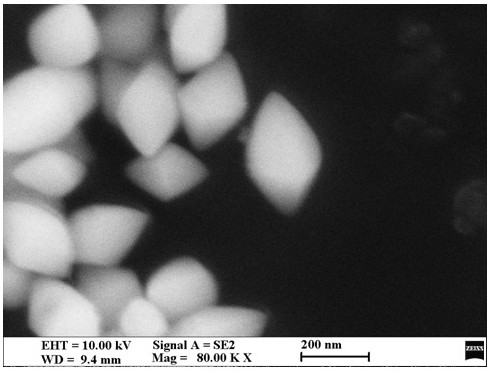

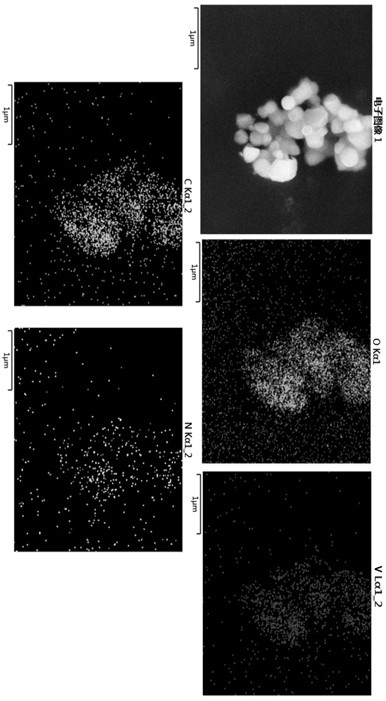

[0026] Accurately weigh 0.1 g of a monodisperse spindle-shaped iron oxide sample, dissolve it in 50 mL of deionized water, prepare an iron oxide solution, disperse it ultrasonically for 20 min, and mark it as solution A. Accurately weigh 0.15 g of dopamine hydrochloride, dissolve it in 50 mL of deionized water, then add 0.2 mg of vanadyl ethylene acetonate, ultrasonically disperse for 30 min, and mark it as solution B. Then add solution B to solution A, stir at room temperature for 30 minutes, add 40 mL of tris-hydrochloric acid solution (0.24 g of tris, 6 mL of hydrochloric acid, and 34 mL of deionized water), and continue stirring at room temperature for 12 hours After the reaction, the reaction solution was repeatedly suction filtered and dried for later use. The dried sample was calcined in a nitrogen-protected muffle furnace at 900°C for 2 hours to remove organic impurities. After cooling, the calcined sample was placed in 5% dilute hydrochloric acid solution to repeatedl...

Embodiment 2

[0029] Accurately weigh 0.1 g of a monodisperse spindle-shaped iron oxide sample, dissolve it in 50 mL of deionized water, prepare an iron oxide solution, disperse it ultrasonically for 20 min, and mark it as solution A. Accurately weigh 0.15 g of dopamine hydrochloride, dissolve it in 50 mL of deionized water, then add 0.4 mg of vanadyl ethylene acetonate, ultrasonically disperse for 30 min, and mark it as solution B. Then add solution B to solution A, stir at room temperature for 30 minutes, add 40 mL of tris-hydrochloric acid solution (0.24 g of tris, 6 mL of hydrochloric acid, and 34 mL of deionized water), and continue stirring at room temperature for 12 hours After the reaction, the reaction solution was repeatedly suction filtered and dried for later use. The dried sample was calcined in a nitrogen-protected muffle furnace at 900°C for 2 hours to remove organic impurities. After cooling, the calcined sample was placed in 5% dilute hydrochloric acid solution to repeatedl...

Embodiment 3

[0032] Accurately weigh 0.1 g of a monodisperse spindle-shaped iron oxide sample, dissolve it in 50 mL of deionized water, prepare an iron oxide solution, disperse it ultrasonically for 20 min, and mark it as solution A. Accurately weigh 0.15 g of dopamine hydrochloride, dissolve it in 50 mL of deionized water, then add 0.6 mg of vanadyl ethylene acetonate, ultrasonically disperse for 30 min, and mark it as solution B. Then add solution B to solution A, stir at room temperature for 30 minutes, add 40 mL of tris-hydrochloric acid solution (0.24 g of tris, 6 mL of hydrochloric acid, and 34 mL of deionized water), and continue stirring at room temperature for 12 hours After the reaction, the reaction solution was repeatedly suction filtered and dried for later use. The dried sample was calcined in a nitrogen-protected muffle furnace at 900°C for 2 hours to remove organic impurities. After cooling, the calcined sample was placed in 5% dilute hydrochloric acid solution to repeatedl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com