Small sewage treatment system with full-buried reinforced concrete structure and treatment method

A sewage treatment system, buried technology, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Physical filtration and other issues, to achieve the effect of easy discharge, good treatment effect and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

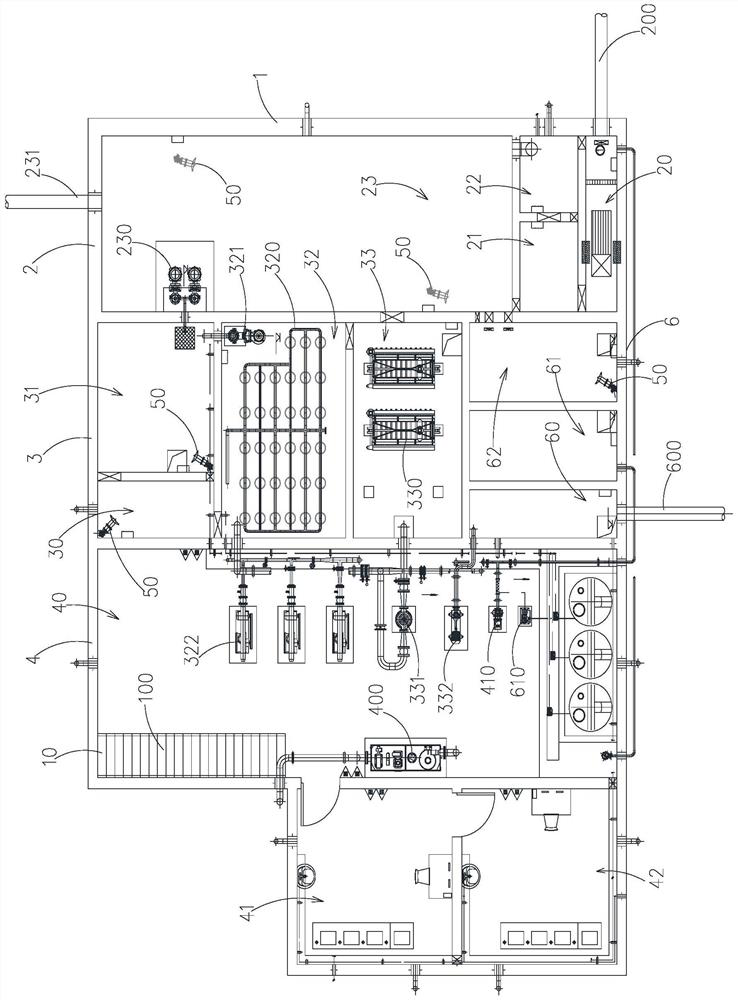

[0036] This embodiment takes a typical sewage treatment system with a sewage treatment capacity of 250 tons / day as an example to illustrate the structure and working mode of the sewage treatment system of the present invention.

[0037] refer to figure 1 ,lie in figure 1 On the far right is the pretreatment area 2, in which a physical filter device is installed to filter out particulate impurities and oil stains in the sewage, and the downstream of the pretreatment area 2 is connected to the biochemical treatment area 3.

[0038] Specifically, the physical filtering device in the pretreatment area 2 includes a water inlet channel 20 , a grit chamber 21 , a grease trap 22 and a regulating tank 23 , wherein the water inlet channel 20 communicates with a sewage water source through a water inlet pipe 200 .

[0039] In the water inlet channel 20, artificial grilles and mechanical grilles are arranged in sequence along the direction of sewage flow. The artificial grills (pore size...

Embodiment 2

[0055] This embodiment also provides a sewage treatment method for a small-scale sewage treatment system with a fully buried reinforced concrete structure in the first embodiment, including the following steps:

[0056] S1. The sewage flows through the pretreatment area 2, and the sewage entering through the water inlet channel 20 is filtered through the artificial grid and the mechanical grid to filter out the floating matter and large-pore particles in the sewage, and the grit chamber 21 and the grease trap 22 Remove large specific gravity particles and surface oil, reduce the burden of subsequent biochemical treatment through physical filtration, and save the cost of biochemical treatment.

[0057] S2. The sewage flows through the anaerobic pool 30, the anoxic pool 31, the aerobic pool 32, and the membrane pool 33 in the biochemical treatment area 3 in order to denitrify and dephosphorize the sewage, and return the sludge through the first return pipeline 331 to Maintain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com